Flue gas discharge continuous monitoring system based on image processing

A flue gas emission and image processing technology, applied in measurement devices, color/spectral property measurement, material analysis by optical means, etc., can solve the problems of high cost, limited scope of application, high cost and equipment loss, and achieve high sensitivity and accuracy, easy installation and maintenance, and strong function expansibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

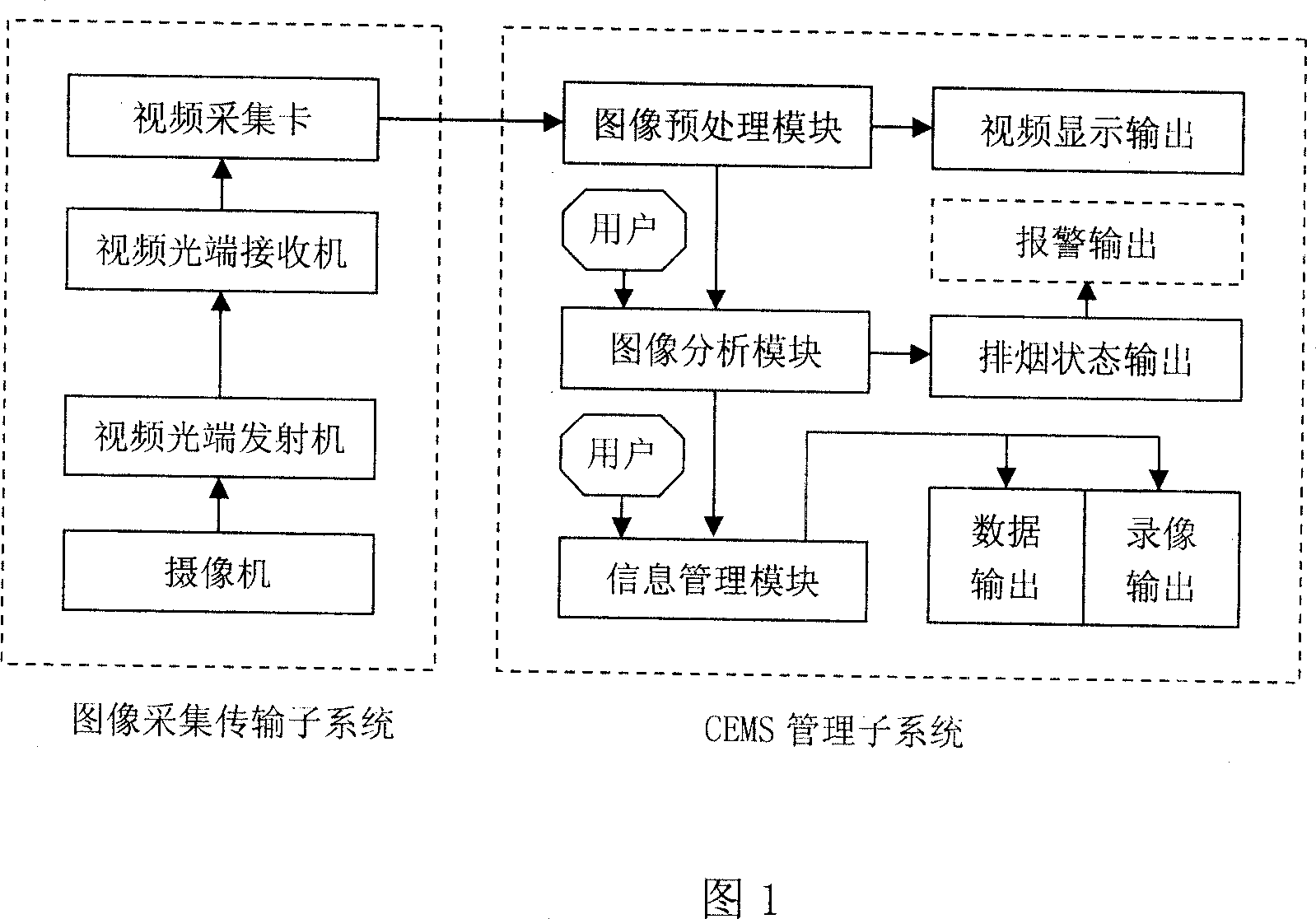

[0033] As shown in Figure 1, the analog video information collected by the front-end camera is transmitted to the local area through optical fiber communication, and converted into digital video information by the video acquisition card, that is, digital image sequence. In the following image preprocessing, the sequenced digital images are first converted from YUV format to RGB format, and then through filtering, sharpening, histogram transformation and other necessary processing to enhance their image quality, and then at a certain frame rate in the software displayed in real time on the interface.

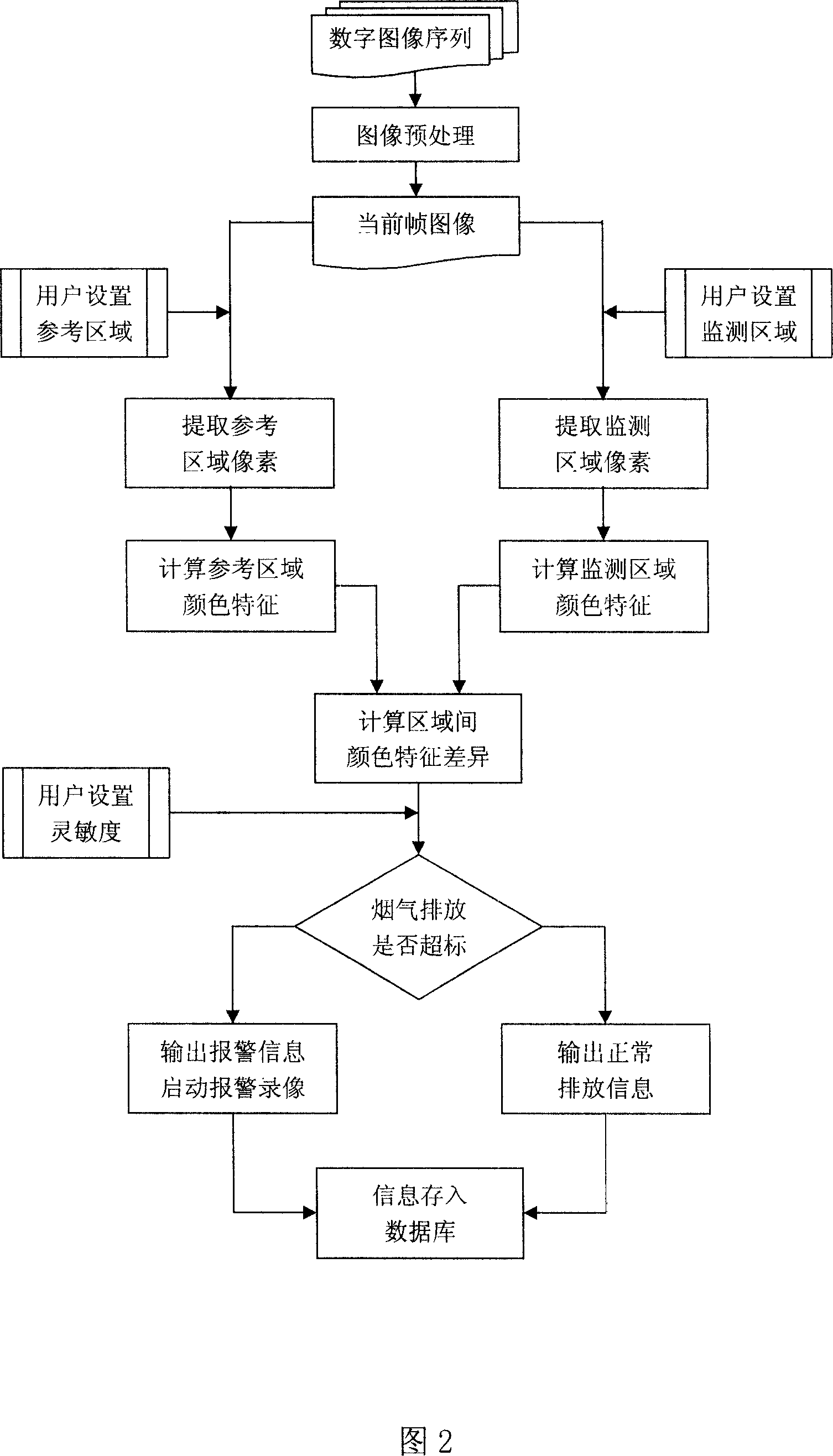

[0034] The subsequent image analysis module is the core of realizing the smoke monitoring function, and the processing steps are as follows:

[0035] 1. First obtain the reference area set by the user (specified as 8×8 pixel size) and the monitoring area;

[0036] 2. According to the reference area and monitoring area set by the user, the area positioning and pixel extraction ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com