Oxide layer adhesion-tight hot-rolled black-skin surface steel sheet and its manufacturing method

A manufacturing method and oxide layer technology, applied in the field of hot-rolled steel plates, can solve problems affecting production efficiency, etc., and achieve the effects of improving service life, saving energy, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

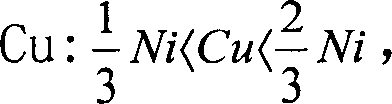

[0029] Below by embodiment the present invention will be further described. Firstly, steel grades are designed according to the composition scope of the present invention. The embodiment of the present invention provides 8 steel grade compositions, and the specific compositions are shown in Table 1. Then the steel billets with different components are heated, kept warm, rough rolled, descaled, finished rolled, cooled and coiled according to the prescribed rolling system. The present invention provides 14 embodiments of rolling systems, see Table 2 for details. See Table 3 for the steel plate performance and oxide layer conditions corresponding to each embodiment. As can be seen from Table 3, the mechanical properties of the steel plate of the embodiment of the present invention fully meet the requirements of the steel plate supply performance standard, and the thickness of the surface oxide layer and the Fe 3 o 4 content met the design requirements. For those that need to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com