Novel high-pressure frequency variator low energy-consumption load testing method

A high-voltage frequency converter and load test technology, which is applied in the direction of instrumentation, power supply testing, and measurement of electrical variables, can solve problems such as low reliability and safety, complex test systems, and difficult control, and achieve simple control, simple test systems, and High practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

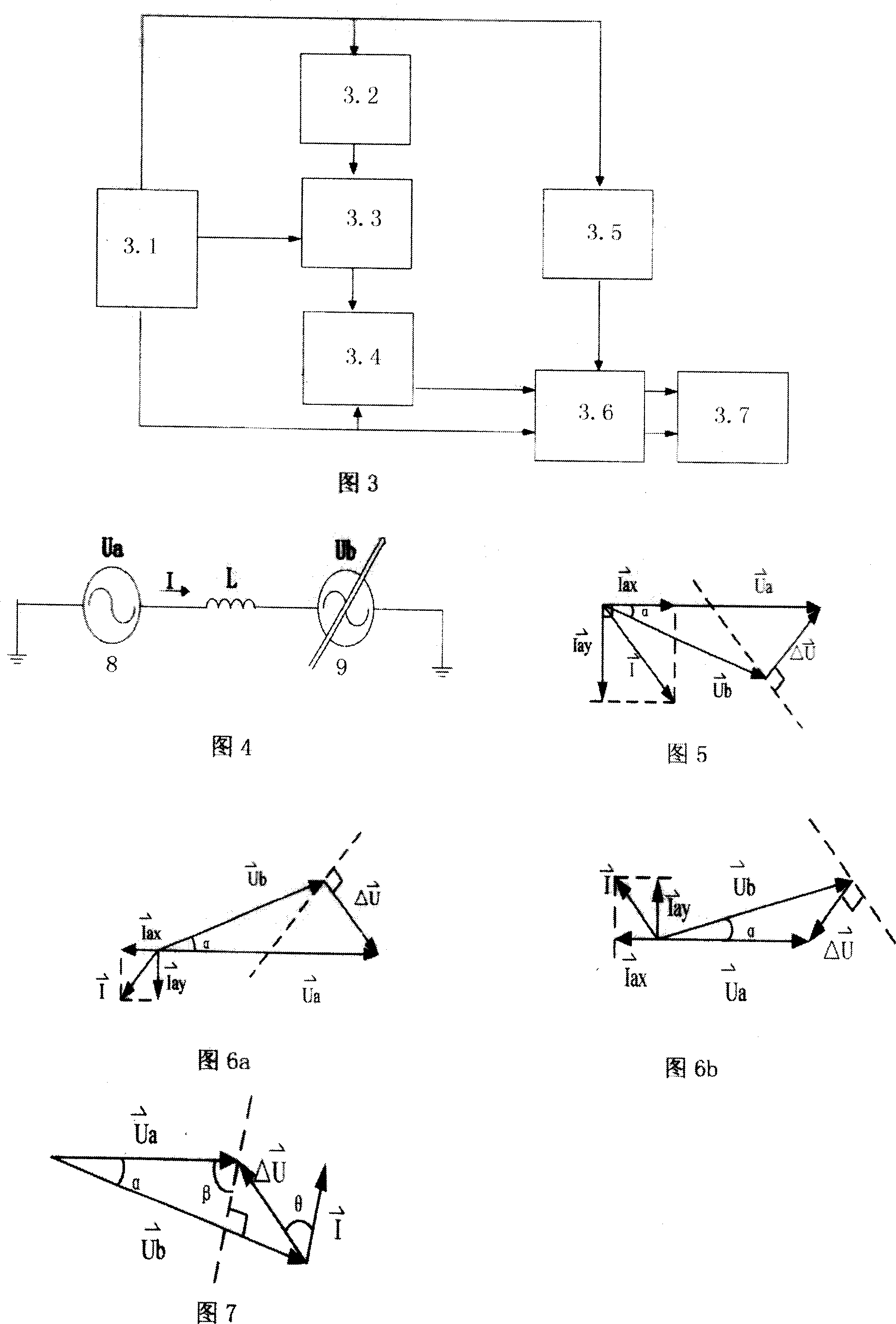

[0024] The working principle of the present invention will be further described below in conjunction with the accompanying drawings and unit embodiments.

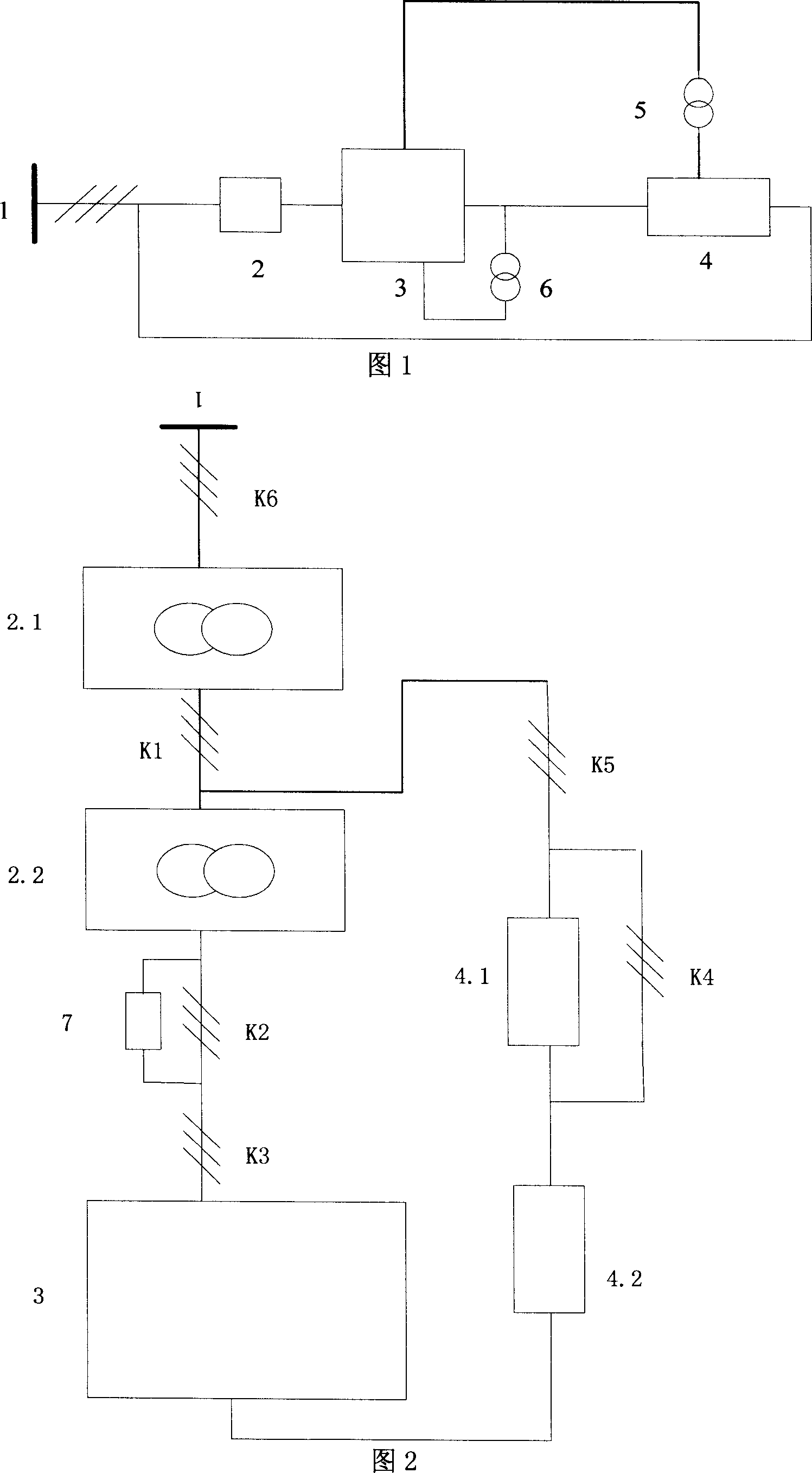

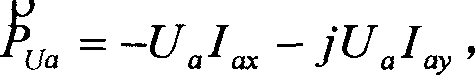

[0025] As shown in Fig. 1 test principle diagram of the present invention. The busbar 1 of the distribution network is connected to the frequency converter 3 through the isolation transformer 2, and its output end is connected in parallel with the busbar 1 after the resistive load 4 is connected in series. It is determined by the voltage of the resistor in the resistive load, because when the unit output voltage and phase are consistent with the input AC voltage, the active power consumption of the system is theoretically 0, and the resistor voltage drop should also be 0 theoretically, but due to the existence of frequency conversion The loss of the resistor, the resistance voltage drop should be a value close to 0. In fact, finding its minimum value means that the output and input AC are consistent in size and phase. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com