Process for metallic contamination reduction in silicon wafers

A technology of silicon wafers and impurities, applied in the field of semiconductor material substrates, can solve problems such as limitations, increased wafer costs, and reduced yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

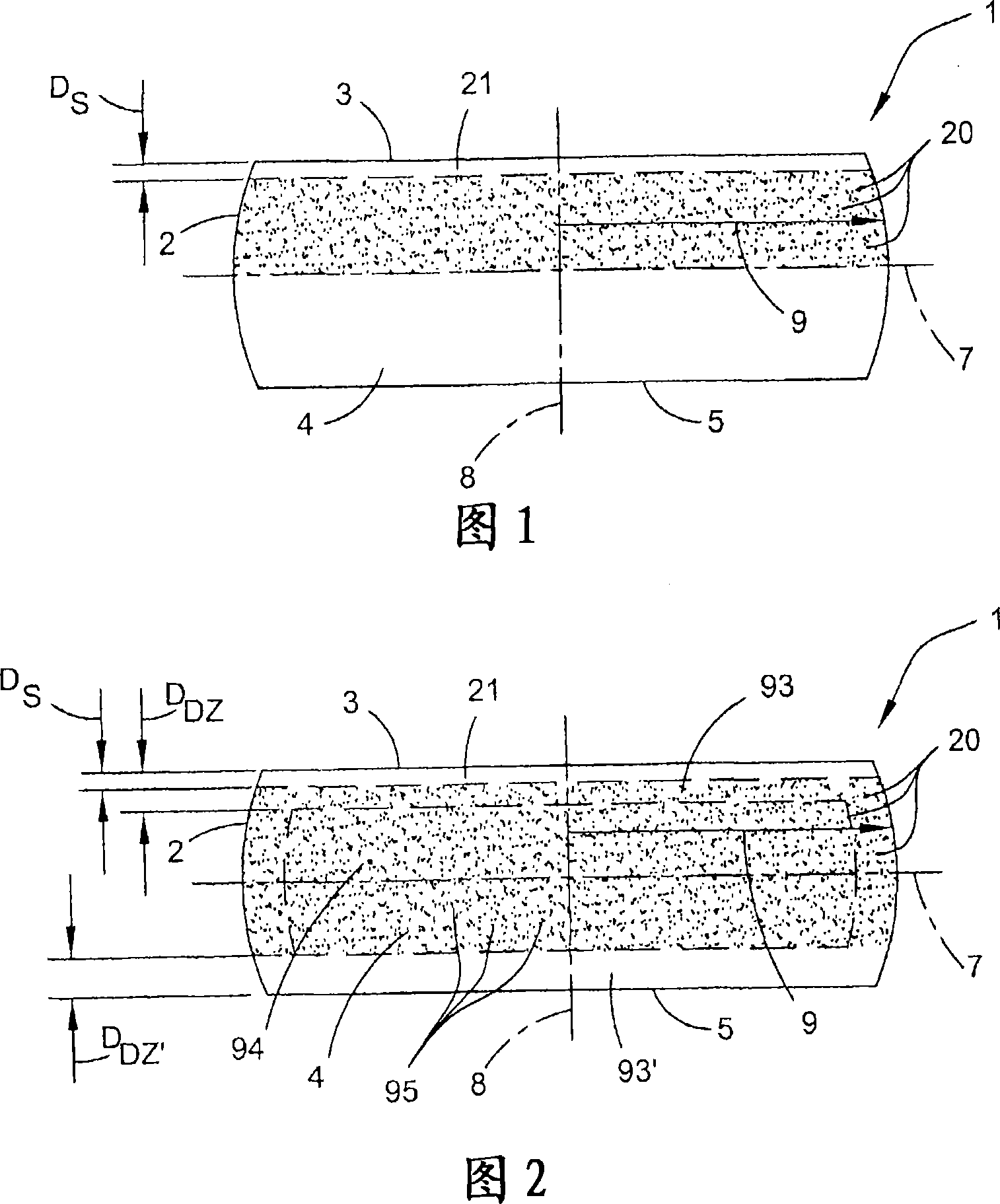

Image

Examples

Embodiment Construction

[0015] The following discussion focuses on copper impurities in silicon; copper is the most studied and is usually the biggest problem among metallic impurities. However, the methods described here for copper are also applicable to other metallic impurities found in silicon (eg, nickel, iron, aluminum, chromium, etc.).

[0016] Without being bound to any particular theory, the copper is thought to form some sort of complex with boron and in this way be bound or "stored" in the boron-doped silicon wafer. In addition, these copper-boron complexes are also believed to be metastable even at room temperature. Thus, over time, these complexes dissociate, leaving the copper in interstitial positions. Copper is a fast diffuser in silicon; the fastest of all metals and very active even at room temperature. However, the solubility of copper in silicon is very temperature dependent and very low at low temperatures such as room temperature. Therefore, at low temperatures, interstitial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com