Nano ferric oxide material and its preparing process and use in water treatment

A technology of nanomaterials and oxides, which is applied in ferrous oxides, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of lengthy and complicated steps, limited application, high price, etc., and achieve high specific surface area , The reaction conditions are not high, and the effect of the ability to remove pollutants is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

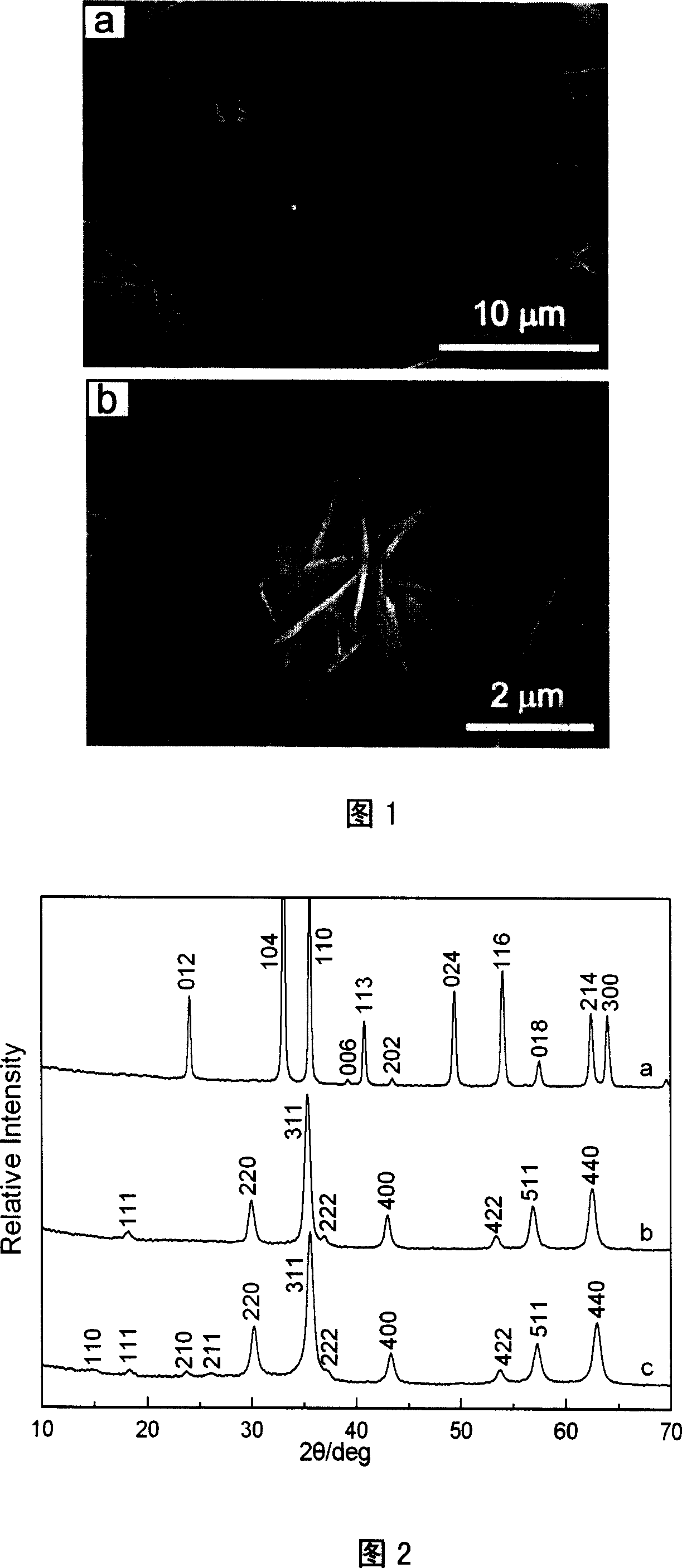

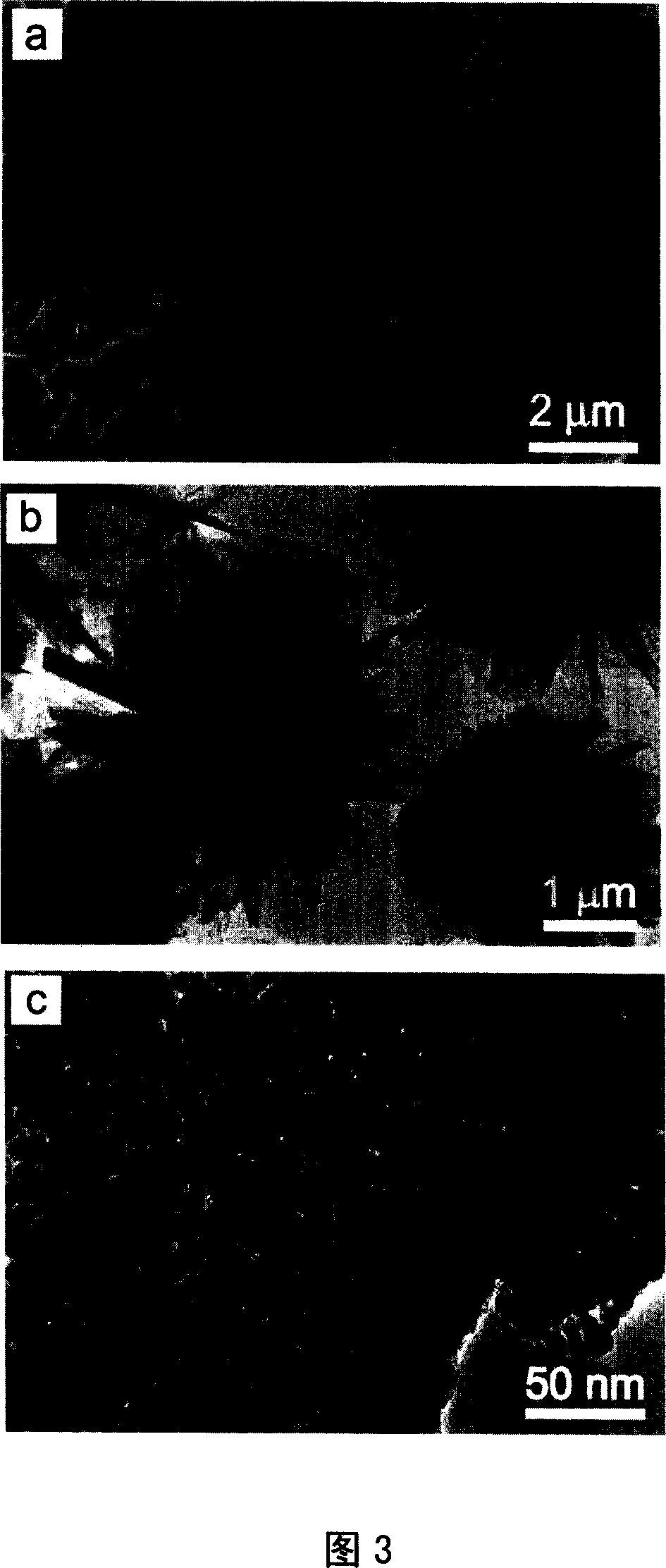

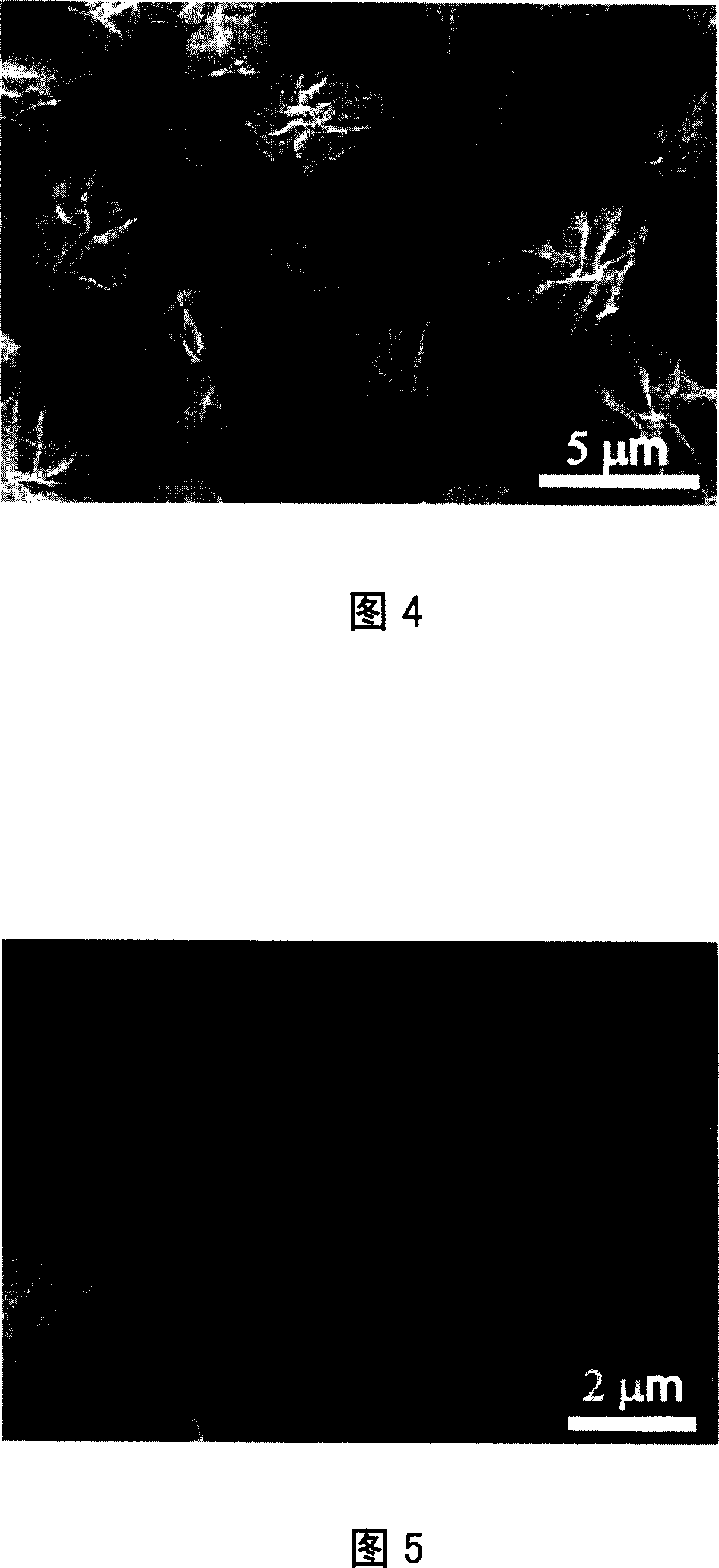

Image

Examples

Embodiment 1

[0046] 1.2 g of ferric chloride hexahydrate, 2.7 g of urea and 7.2 g of tetrabutylammonium bromide were added to 180 ml of ethylene glycol, followed by heating with stirring. Heating was stopped after 30 minutes at reflux. After the solution was cooled to room temperature, the precipitate was centrifuged and washed four times with absolute ethanol, and then the washed precipitate was dried in an oven at 70° C. for 12 hours to obtain the iron precursor.

[0047] Put the obtained iron precursor into a muffle furnace, heat from room temperature to 450°C in an air atmosphere (the heating rate is about 40°C / min), stop heating after constant temperature for 3 hours, and cool to room temperature to obtain α-Fe 2 o 3 ; The precursor of the iron obtained is put into a tube furnace, and high-purity nitrogen gas is fed into the tube furnace for 30 minutes, and then heated from room temperature to 450° C. (the heating rate is about 40° C. / min) while continuing to feed nitrogen gas. Aft...

Embodiment 2

[0049] Trisodium arsenate (Na 3 AsO 4 12H 2 (0) and ultra-clean water to prepare a solution with arsenic concentration of about 10ppm (mg / L), and adjust the pH value to 4 with hydrochloric acid or sodium hydroxide solution. Get the prepared arsenic solution of 25ml, add 0.05g α-Fe prepared by the present invention wherein 2 o 3 nanomaterial and start stirring. After 30 minutes, solid-liquid separation was performed by centrifugation, and the supernatant was collected. The content of arsenic in the solution was measured by inductively coupled plasma atomic emission spectroscopy (ICP-AES). The results are shown in Table 1.

Embodiment 3

[0051] By the same procedure in Example 2, but the adsorbent added is Fe prepared by the present invention 3 o 4 nanomaterials. The results are shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap