Production process and application of multifunctional nano waterproof agent

A production method and technology of waterproofing agent, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problem of not being suitable for mass production, etc., and achieve the effect of strong waterproof function

Inactive Publication Date: 2007-06-27

黄希锋

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Most of the existing waterproofing agents are water-based materials, which need to be heated and dried or left to dry for a long time to achieve the waterproof effect, which is not suitable for industrial mass production

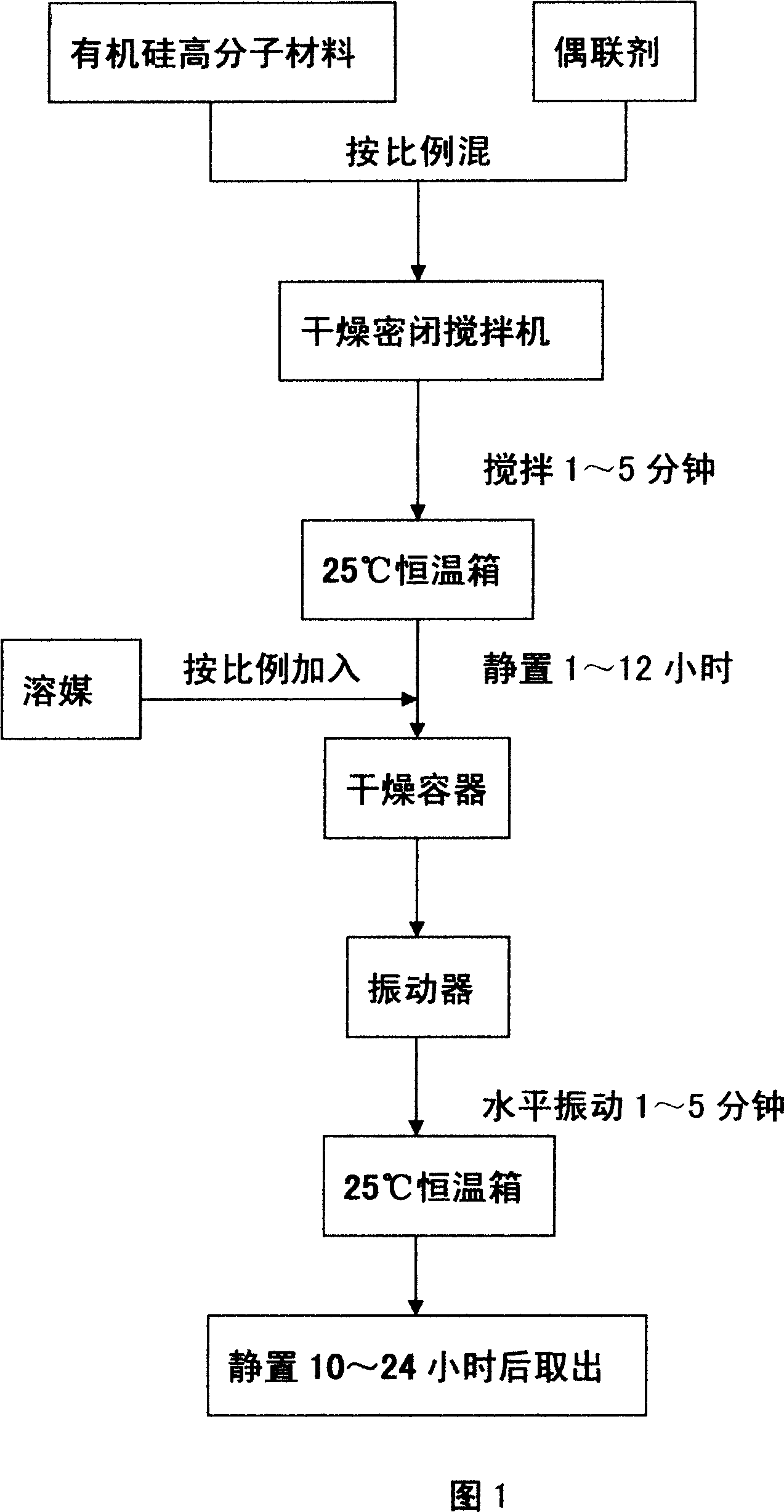

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

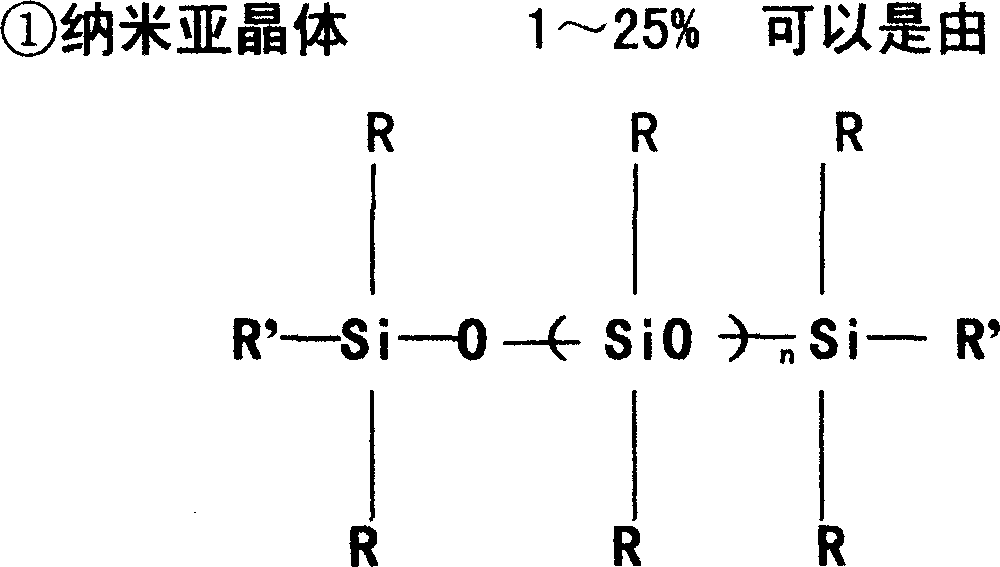

[0041] Components: Weight:

[0042]

[0043] Isopropyl Trioleoyl Titanate 10%

[0044] Ether 70%

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

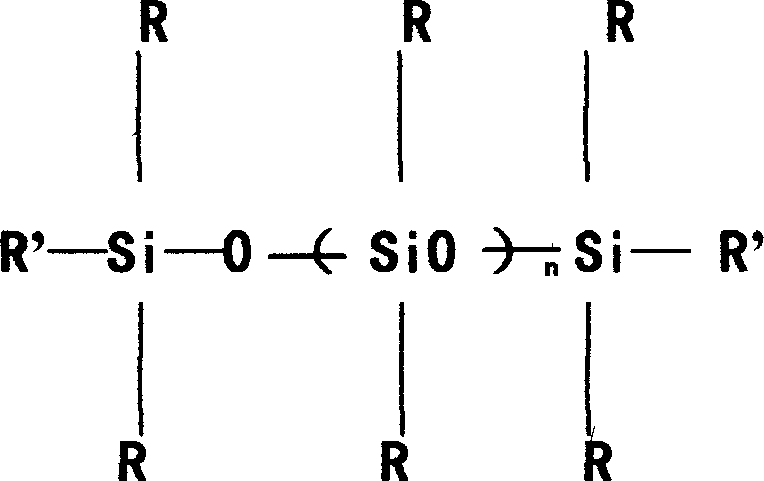

The multifunctional nanometer waterproof agent consists of nanometer subcrystal and solvent mainly, and reaches the waterproof effect through coating fiber with nanometer grains with hydrophobic functional group. The present invention features that the multifunctional nanometer waterproof agent may be used widely for fibrous material to reach waterproof effect, ventilating effect, antifouling effect and antimildew effect.

Description

technical field [0001] The invention is a chemical preparation for changing the waterproof performance of fiber-containing articles, so that the fiber-containing articles have a strong waterproof function. Background technique [0002] Natural fiber-containing items such as wood products, leather, and paper products are prone to mildew, deformation, and brittleness due to moisture absorption, which seriously affects product quality. [0003] At present, there have only been reports about leather waterproof and breathable materials in Ludwig's laboratory in Germany. Moreover, the laboratory's technology is not very mature, and the product can only be applied to leather. It can be applied on flexible materials, and the material has waterproof effect without changing the softness, air permeability, color, appearance, feel, etc., and the product that is convenient to use and simple in process has not been found. From a technical point of view, it is also very difficult to brea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K3/18

Inventor 黄希锋

Owner 黄希锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com