Waterproof material for electronic controller and preparation method thereof

A technology for electronic controllers and waterproof materials, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as bulkiness, damage, and paint poisoning, and achieve simple preparation process and reduce production costs , the effect of strong waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

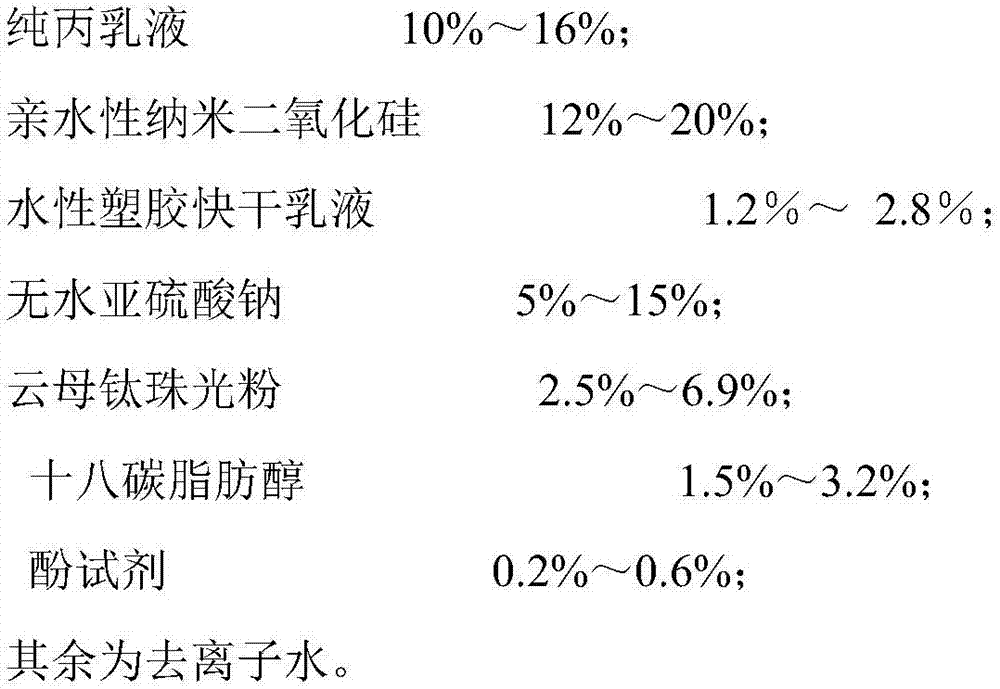

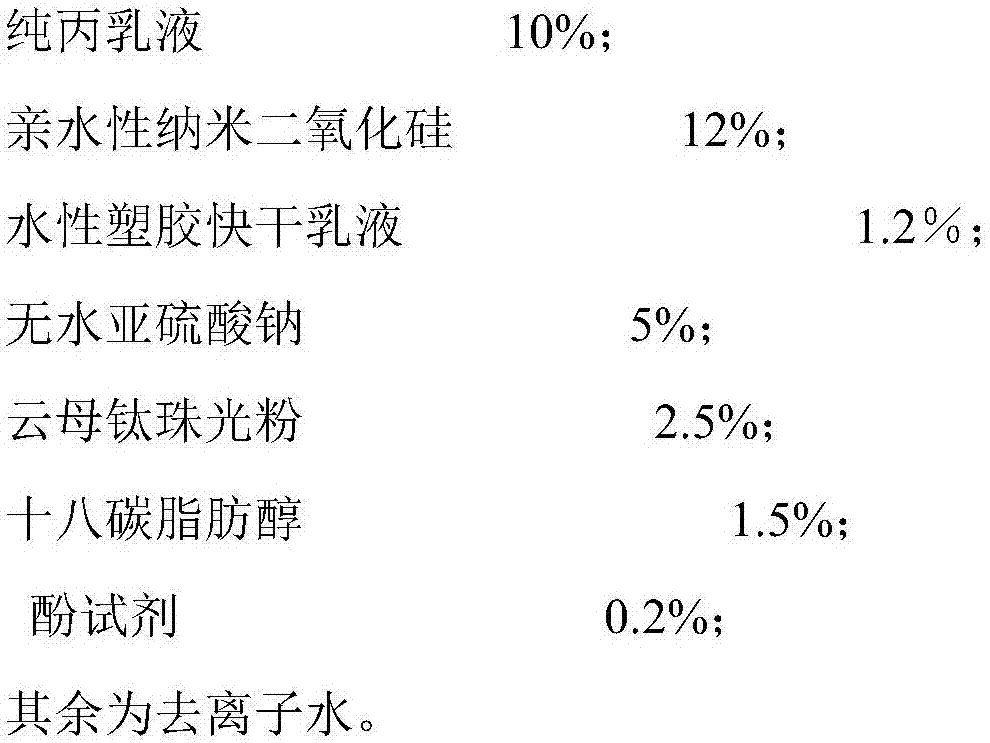

Embodiment 1

[0023] Embodiment 1. Weigh 10kg of pure acrylic emulsion, then slowly add it into a reaction kettle filled with appropriate deionized water through an automatic feeding system, and stir fully. The stirring temperature is 40 degrees, and the stirring pressure is 1.2Mpa. Stir The time was 10 minutes, and the stirring speed was 45 rpm;

[0024] Then take by weighing 12kg of hydrophilic nano silicon dioxide, 1.2kg of water-based plastic quick-drying emulsion, 5kg of anhydrous sodium sulfite, 2.5kg of isopropyl n-sulfide, 0.2kg of phenol reagent, 1.5% kg of octadecyl Carbofatty alcohol and appropriate deionized water, and fully stirred, the stirring temperature is 30 degrees, the stirring air pressure is 2.2Mpa, the stirring time is 15 minutes, and the stirring speed is 55 rpm;

[0025] Finally, start the diaphragm pump, circulate the prepared mixture through a 0.2um filter for 2 hours, and then filter through a 0.12μm filter to remove harmful particles with a particle size greater...

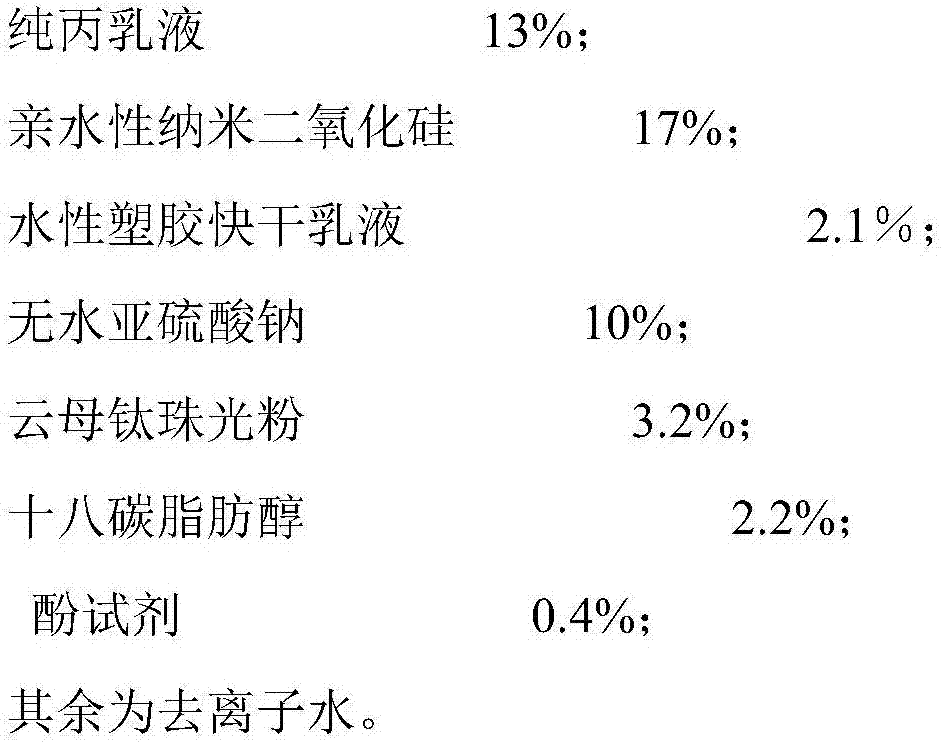

Embodiment 2

[0027] Embodiment 2. Weigh 13kg of pure acrylic emulsion, then slowly add it into a reaction kettle filled with appropriate deionized water through an automatic feeding system, and fully stir. The stirring temperature is 50 degrees, and the stirring pressure is 1.7Mpa. Stir The time was 12 minutes, and the stirring speed was 45 rpm;

[0028] Then take by weighing 17kg of hydrophilic nano silicon dioxide, 2.2kg of water-based plastic quick-drying emulsion, 10kg of anhydrous sodium sulfite, 4.5kg of isopropyl n-sulfide, 0.4kg of phenol reagent, 2.5% kg of octadecyl Carbofatty alcohol and appropriate deionized water, and fully stirred, the stirring temperature is 35 degrees, the stirring air pressure is 2.9Mpa, the stirring time is 20 minutes, and the stirring speed is 65 rpm;

[0029] Finally, start the diaphragm pump, circulate the prepared mixture through a 0.2um filter for 2.5 hours, and then filter through a 0.12μm filter to remove harmful particles with a particle size grea...

Embodiment 3

[0031] Example 3. Weigh 16kg of pure acrylic emulsion, then slowly add it into a reaction kettle filled with appropriate deionized water through an automatic feeding system, and fully stir. The stirring temperature is 60 degrees, and the stirring pressure is 2.3Mpa. Stir The time was 15 minutes, and the stirring speed was 45 rpm;

[0032] Then take by weighing 20kg of hydrophilic nano silicon dioxide, 2.8kg of water-based plastic quick-drying emulsion, 15kg of anhydrous sodium sulfite, 6.9kg of isopropyl n-sulfide, 0.6kg of phenol reagent, 3.2% kg of octadecyl Carbofatty alcohol and appropriate deionized water, and fully stirred, the stirring temperature is 40 degrees, the stirring air pressure is 3.3Mpa, the stirring time is 25 minutes, and the stirring speed is 75 rpm;

[0033] Finally, start the diaphragm pump, circulate the prepared mixture through a 0.2um filter for 3 hours, and then filter through a 0.12μm filter to remove harmful particles with a particle size greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com