Double heater and chemical vapor deposition process for preparing super conductive film therein

A technology of chemical vapor deposition and superconducting thin film, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of affecting film quality, difficult film thickness, poor uniformity, etc., and achieves low cost, The effect of good uniformity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

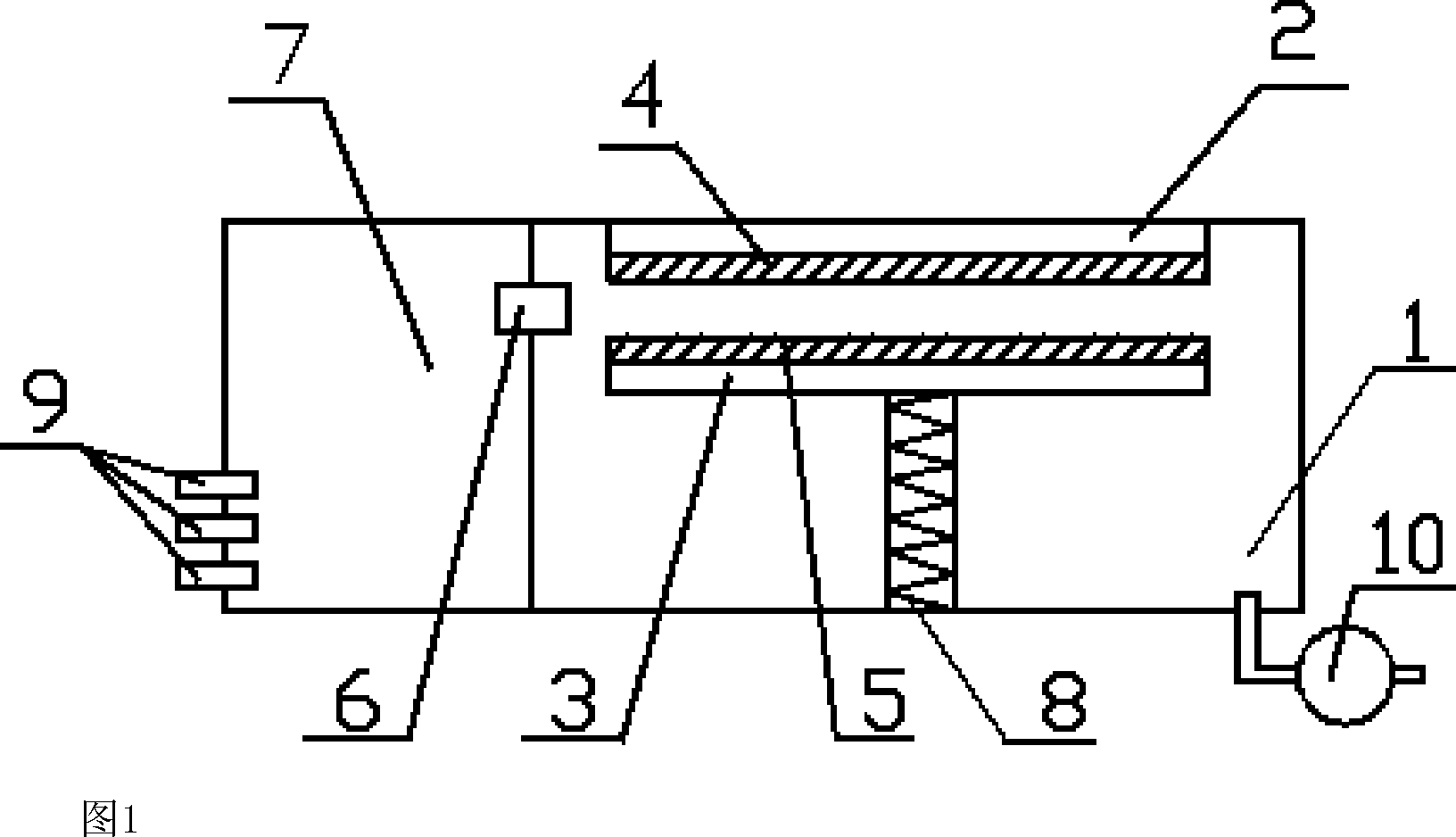

[0016] Embodiment: the substrate heater 2 is fixed above the deposition chamber 1, the substrate placement surface 4 faces downward, the substrate heater 2 is heated by resistance wire, and its heating temperature range is 400-550° C., the magnesium ingot heater 3 is connected with the deposition chamber The bottom of the chamber 1 is connected by a screw 8, the magnesium ingot placement surface 5 is upward, and the heating temperature range of the magnesium ingot heater 3 is 650-800°C. One end of the deposition chamber 1 is provided with a gas mixing chamber 7, and the gas mixing chamber 7 passes through the air vent 6 Connected with the deposition chamber 1 , the gas mixing chamber 7 is provided with an air inlet 9 , and the deposition chamber 1 is provided with a vacuum pump 10 .

[0017] The substrate heater 2 is heated by resistance wire to ensure that the substrate maintains a uniform temperature during the heating process, so that a large-area film can be generated. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com