Method for producing radio frequency identifying antenna and its antenna structure

A manufacturing method and a technology for identifying antennas, which are applied in the structural form of radiating elements, antennas, and antenna components, etc., and can solve problems such as larger component volume, increased resistance value, and reduced sensing distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

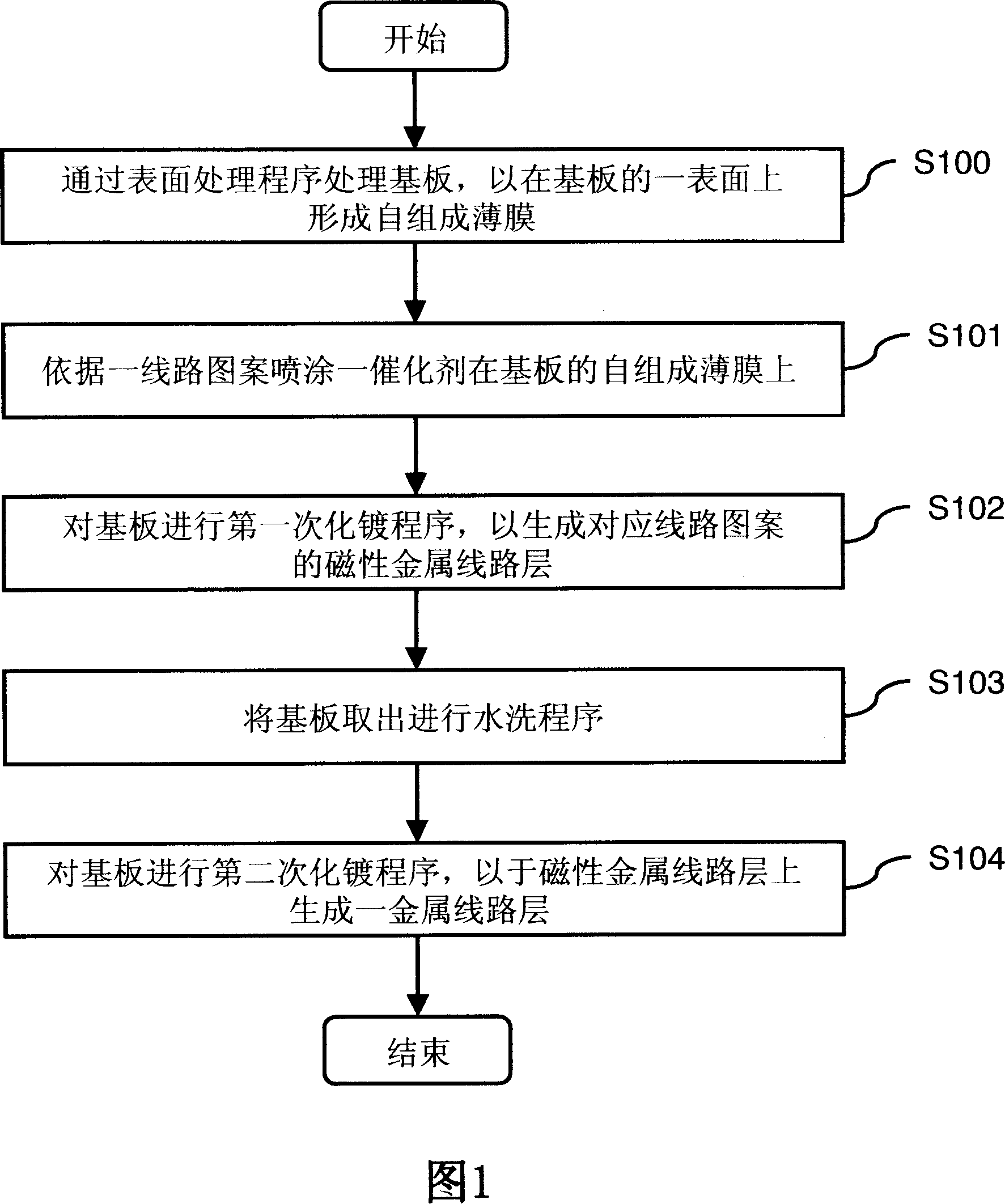

[0028] Please refer to FIG. 1, which is a flow chart of the manufacturing steps of the single-layer radio frequency identification antenna of the first embodiment of the present invention, including:

[0029] In step S100, first, the substrate is treated by a surface treatment program (for example, plasma treatment, ion beam treatment or ozone treatment) to form a self-assembly thin film (Self-Assembly) on a surface (for example, upper surface or lower surface) of the substrate. Membrane, SAM);

[0030] Step S101, spray a catalyst (for example, sodium tetrachloropalladate (Na 2 PdCl 4 ) solution and tetraammonia palladium dichloride (Pd(NH 3 ) 4 Cl 2 ) solution) on the self-composed thin film of the substrate, wherein the micro-droplet generation device uses an inkjet head or a dot array head (arrayer) to spray the catalyst on the substrate.

[0031] Step S102, performing the first electroless plating process on the substrate to generate a magnetic metal (for example, nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com