Method and tunnel drilling machine or selective cutting machine for driving a tunnel borehole

A technology for drilling and excavating machines, used in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as increased wear and tear, and achieve the effect of reducing downtime and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

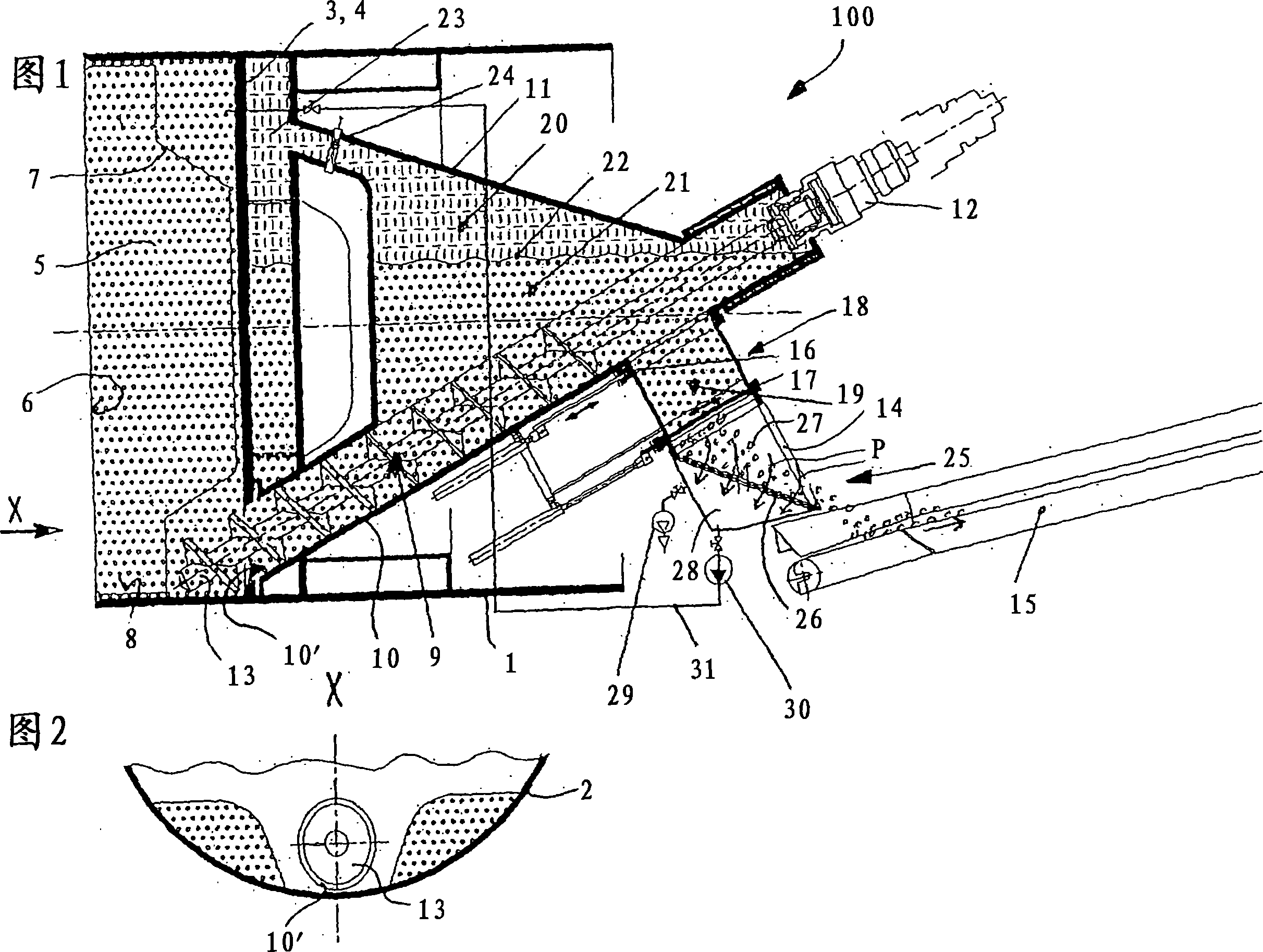

[0045] The tunnel boring machine generally indicated at 100 comprises a body 1 , its outer surface 2 and its rear wall 4 functioning as a rear wall 3 forming a drilling head space 5 behind the working face.

[0046] A drill head 7 of known design works in the drill head space. In the region of the base 8 of the drilling head space 5 a screw conveyor 9 opens into the drilling head space 5 . The screw conveyor 9 has a housing 10 which can be closed in a gas-tight manner relative to the surroundings, which in the closed state only communicates with the drilling head space 5 .

[0047] The housing 10 is initially tubular in the exit region of the drilling head space. Rising in the conveying direction. Adjoining the tubular region of the housing 10 is an upwardly extending groove-shaped extension 11 , which opens into a pressure chamber 23 arranged behind the rear wall 3 . The pressure chamber 23 can be separated from the groove-shaped extension 11 by means of a closing slide va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com