Automatic tuning bed

A hospital bed, automatic technology, applied in the direction of hospital beds, medical science, hospital equipment, etc., can solve the problems of high labor intensity, high cost, damage to the spinal cord, etc., and achieve the effect of good mechanism self-locking performance, lower production costs, and lower labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

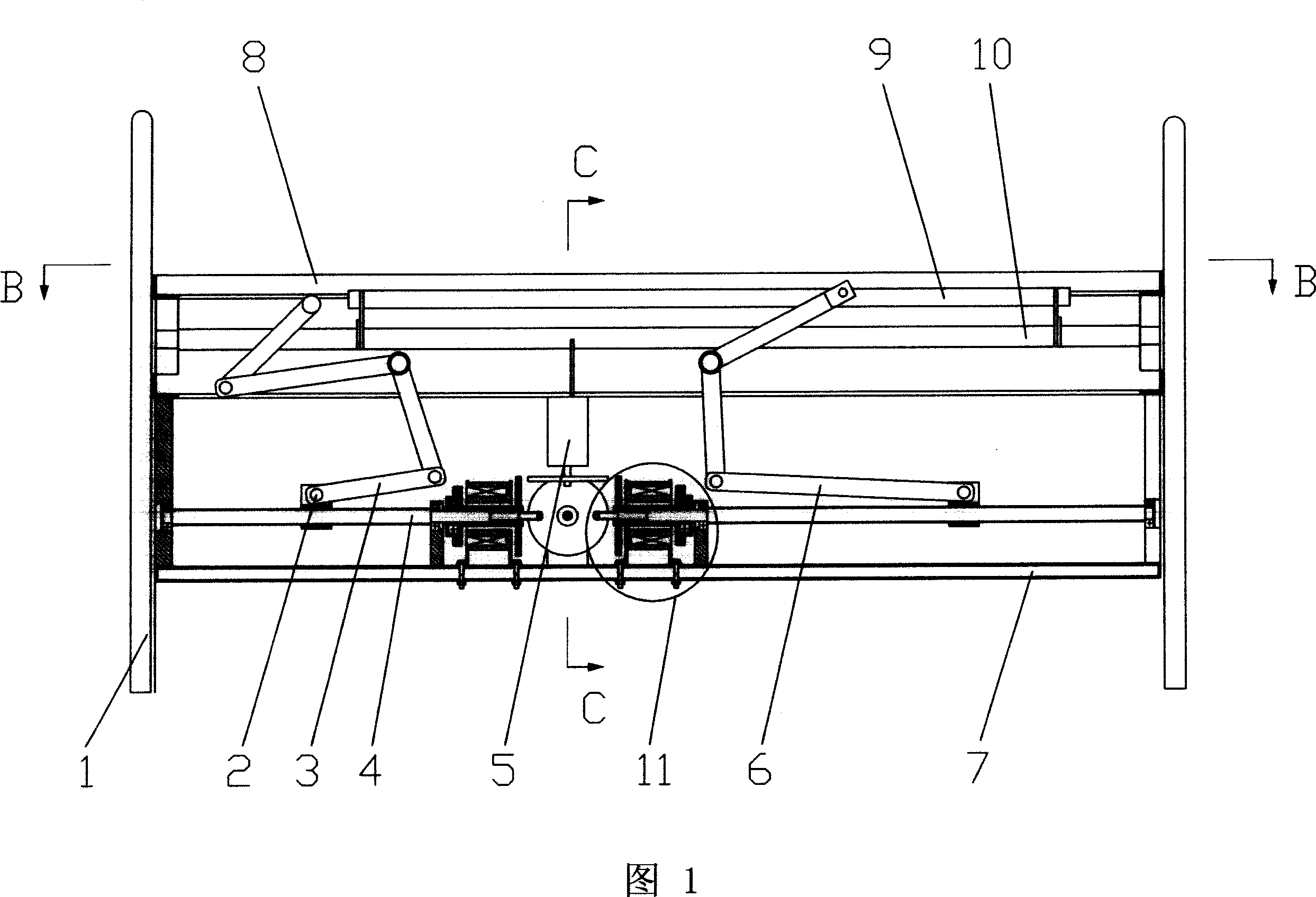

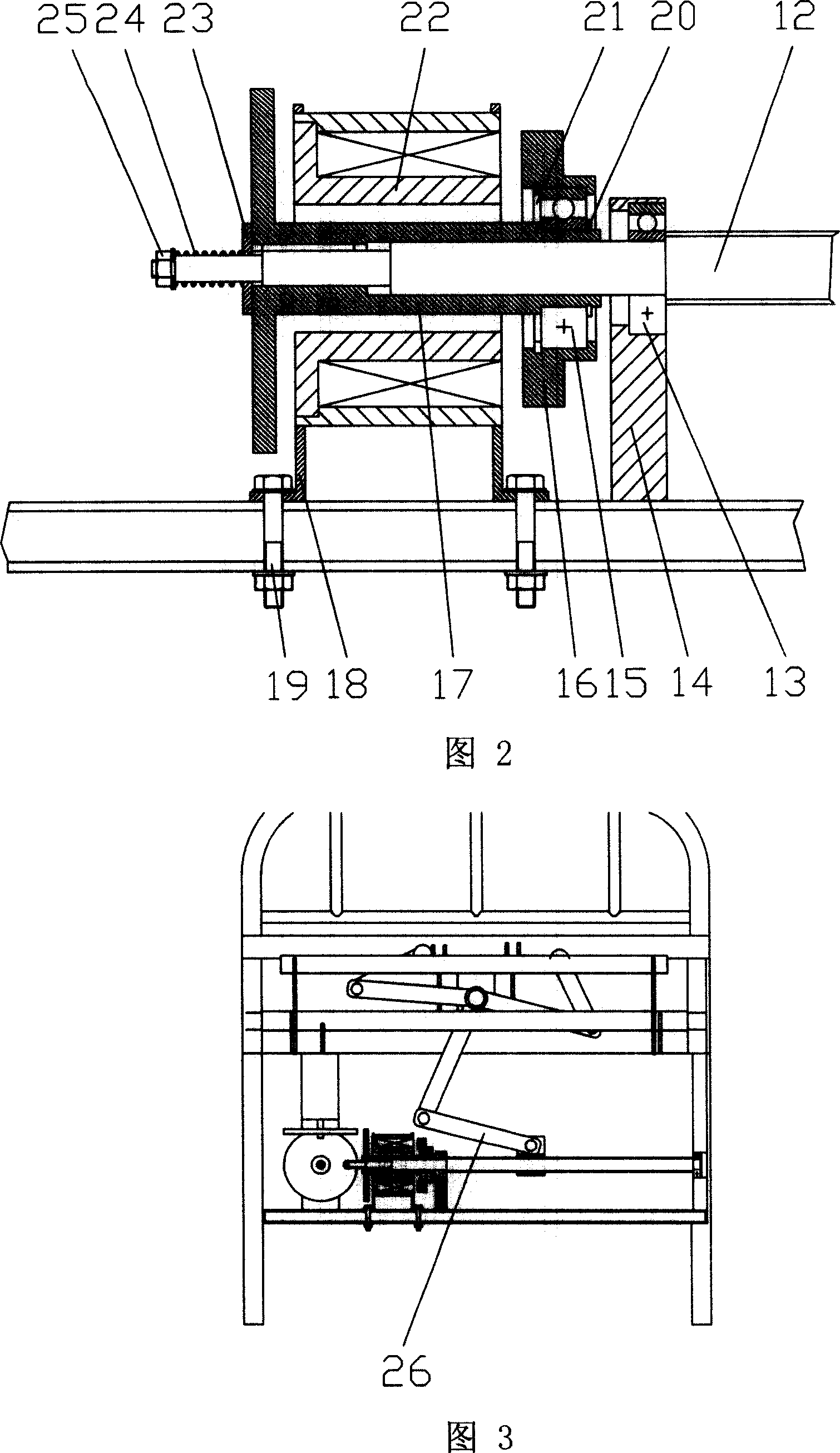

[0021] Press the control button of the direction of getting up, and now the electromagnet is energized, and the magnetic force is generated to hold the static and dynamic separation bearing sleeve suction iron 16, the inner hole of the bearing 13 and the step of the friction wheel 17 are fastened with jump ring 20 and jump ring 21, so that the suction is realized. When the iron moves to the electromagnet, the friction wheel 17 is pushed to slide on the screw mandrel 4, thereby cooperating with the friction wheel of the motor 5, providing positive pressure simultaneously, ensuring normal transmission. At this time, start the motor, and the screw mandrel 4 will make a rotary motion. The rotation of the screw mandrel 4 will drive the transmission nut 2 to move on the screw mandrel 4. The connecting rod and the card position of the linkage mechanism form a hinge to push the bed board. The bed board uses the connection point between the bed boards as the other support to rotate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com