Cleaning method for membrane filter device

A membrane filtration and cleaning liquid technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of deformation of membrane filaments, poor cleaning effect, and insufficient cleaning effect, and achieve extended service life, Good cleaning effect and the effect of reducing the amount of cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

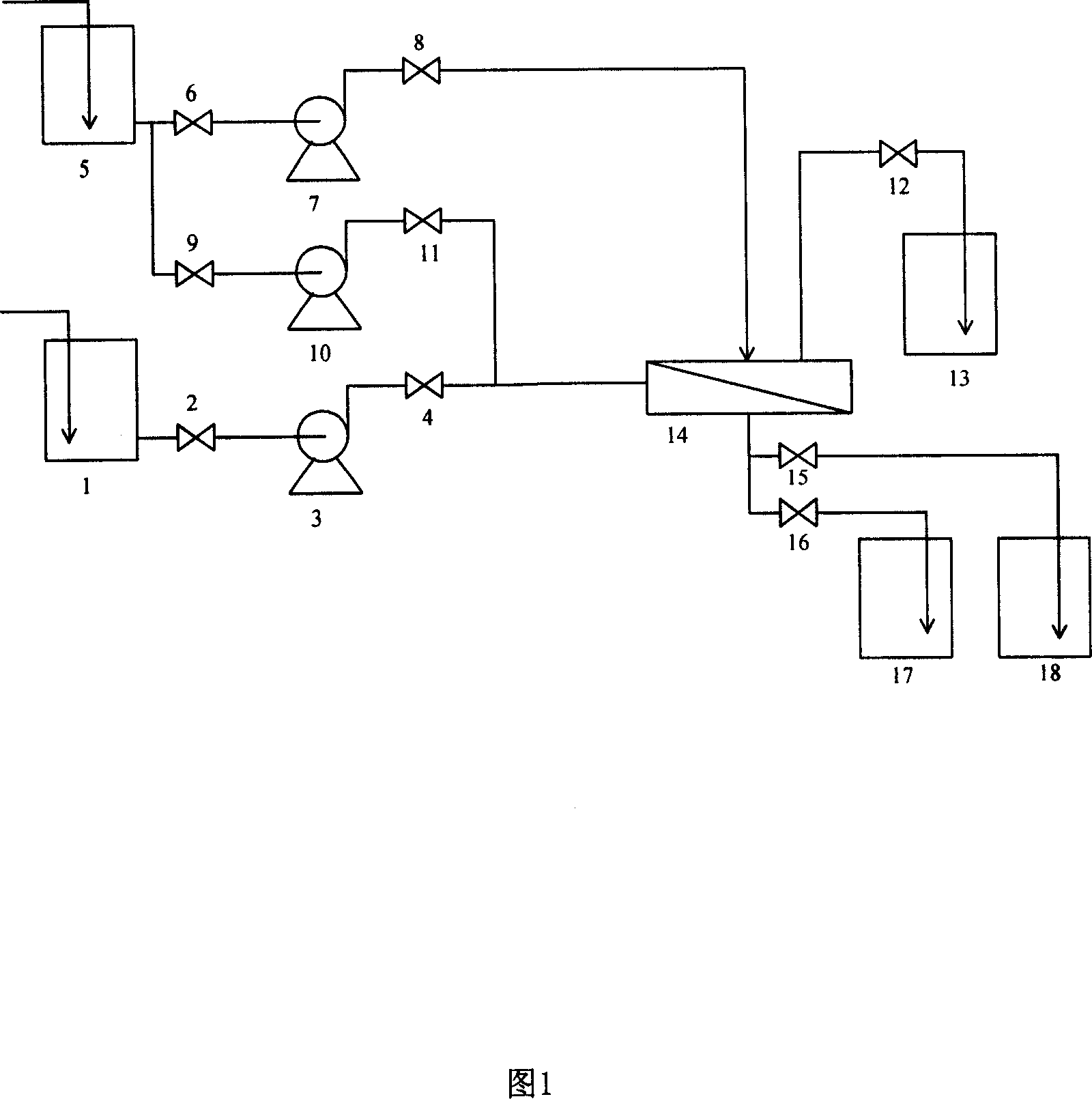

Method used

Image

Examples

Embodiment 1

[0014] The polyvinyl chloride capillary ultrafiltration membrane device filters the fulvic acid solution with a TOC of about 5mg / L. When the flux of the polluted membrane drops to 25% of the initial value, the permeation flux of the membrane after cleaning will only recover 80% at the initial time, and adopt the present invention, promptly adopt forward flushing (forward flushing flow rate is 2.5mL / s) to be full of membrane silk earlier, after about 3sec, start recoil (recoil pressure is 2.0 Mpa), forward recoil At the same time, after 20 sec, the flux of the polluted membrane filaments recovered to 99% of the initial value.

Embodiment 2

[0016] Polyvinyl chloride capillary ultrafiltration membrane device filters polysaccharide solution with a TOC of about 5mg / L. When the flux of the polluted membrane drops to 30% of the initial value, the permeation flux of the membrane after cleaning can only recover to 30% of the initial value. 85% at the initial stage, and adopt the present invention, promptly adopt forward flushing (forward flushing flow rate is 2.8mL / s) to be full of membrane silk first, after about 2.5sec, start recoil (recoil pressure is 2.2Mpa), forward recoil At the same time, after 15 sec, the flux of the polluted membrane filaments recovered to 99% of the initial value.

Embodiment 3

[0018] The polypropylene hollow fiber microfiltration membrane device filters laboratory water with a turbidity of about 15NTU. When the flux of the polluted membrane drops to 20% of the initial value, the permeation flux of the membrane after cleaning can only recover to 20% of the initial value. 85% at the initial stage, and adopt the present invention, promptly adopt forward flushing (forward flushing flow rate is 2.3mL / s) to be full of membrane filament, after about 2sec, start recoil (recoil pressure is 1.5Mpa), forward recoil simultaneously After 18 sec, the flux of the fouled membrane filaments recovered to 99% of the initial value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com