Leakage coaxial optical fiber cable with double-steel-wire reinforced inner conductor and method for making same

A technology of inner conductor and steel wire, applied in the direction of fiber mechanical structure, etc., can solve the problems of low tensile strength, fluctuation of coupling loss, deterioration of leakage coaxial characteristics, etc., to achieve stable and reliable coupling performance, increased tensile strength, and great economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

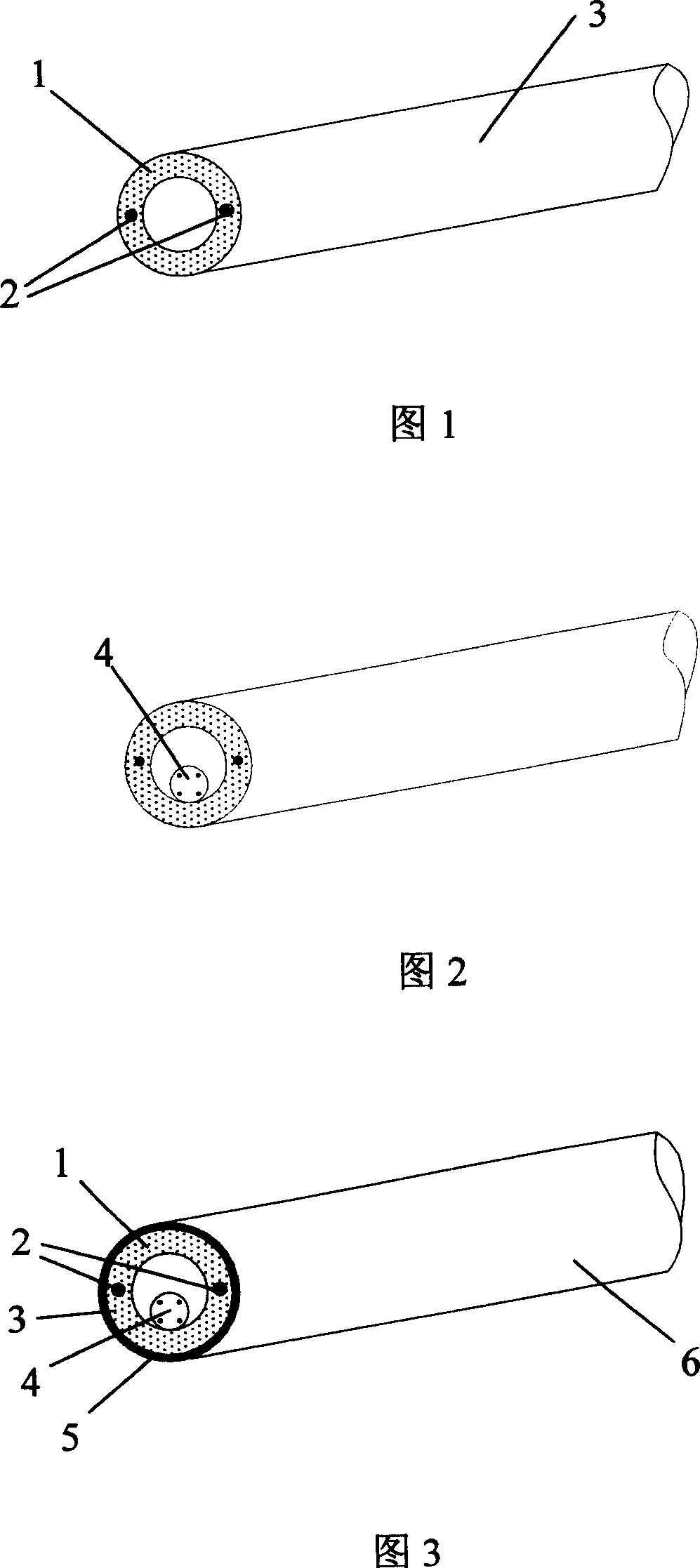

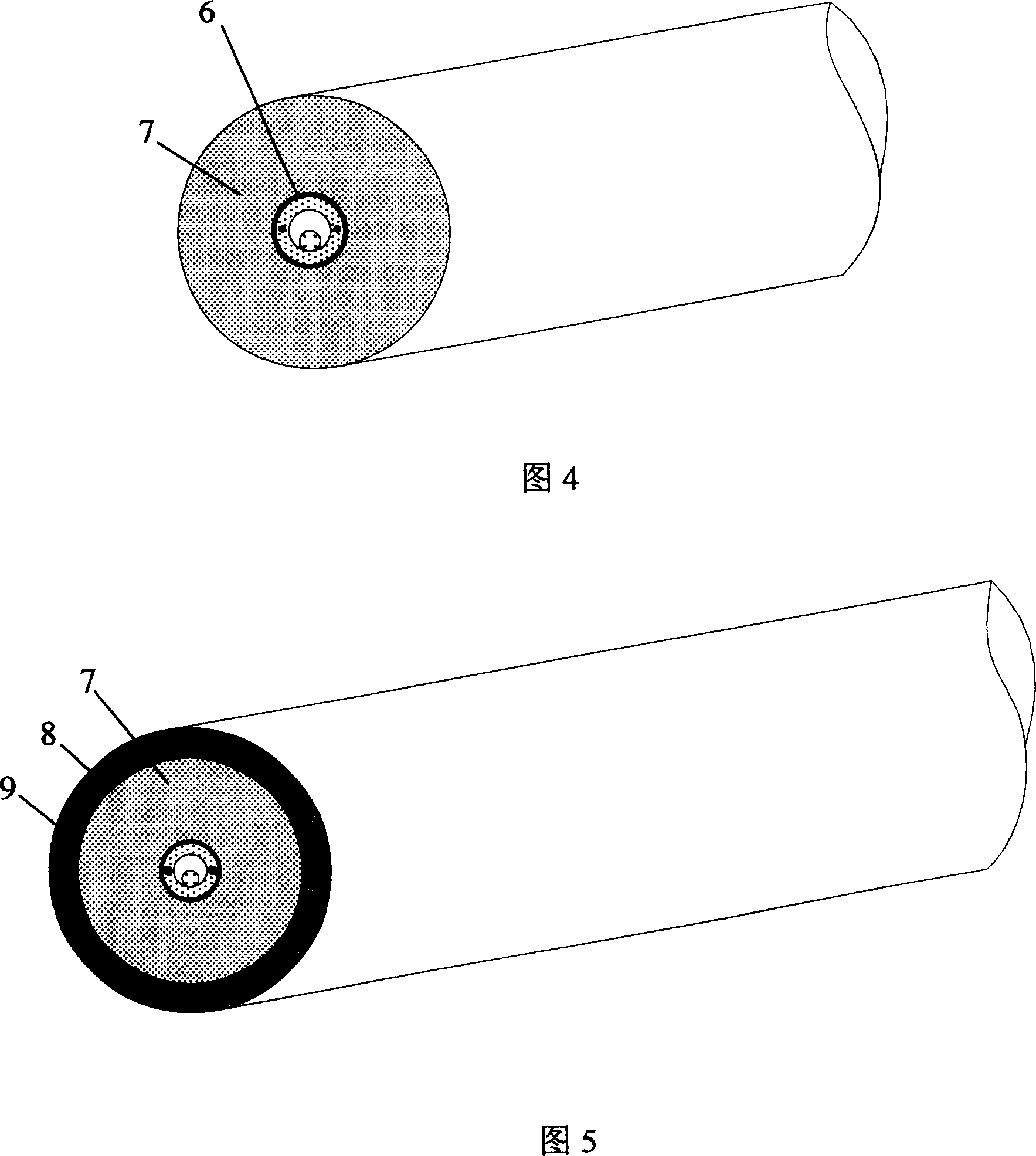

[0020] 1. Strand several optical fibers with SZ, and then enter the extrusion process to form an optical fiber bundle tube containing ointment (4). The oil-filled optical fiber bundle tube (4) with multiple optical fibers is an optical transmission medium for vehicle-to-ground communication, and can constitute a high-quality vehicle-to-ground communication system with photoelectric conversion to ensure driving safety. The number of fibers in the oil-filled bundle is determined by system requirements.

[0021] 2 Put the above-mentioned optical fiber bundle tube (4) into the extruder again. During the extrusion process, two reinforcing steel wires (2) need to be added in parallel, and the extruded plastic empty tube (1) contains the reinforcing steel wire in the tube wall, The two reinforcing steel wires (2) are in the same plane as the center line of the plastic empty pipe (1), thereby constituting the mechanical support body (3) for the inner conductor of the leaky coaxial opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com