Coil component, manufacturing method thereof, and circuit board on which coil component are mounted

a manufacturing method and coil technology, applied in the field of coil components, can solve the problems of low connection reliability, unsuitable power supply use, inconvenient assembly of coil components, etc., and achieve the effect of facilitating the formation of the first and second external terminals, and reducing the thickness of the first magnetic member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Preferred embodiments of the present invention will now be explained in detail with reference to the drawings.

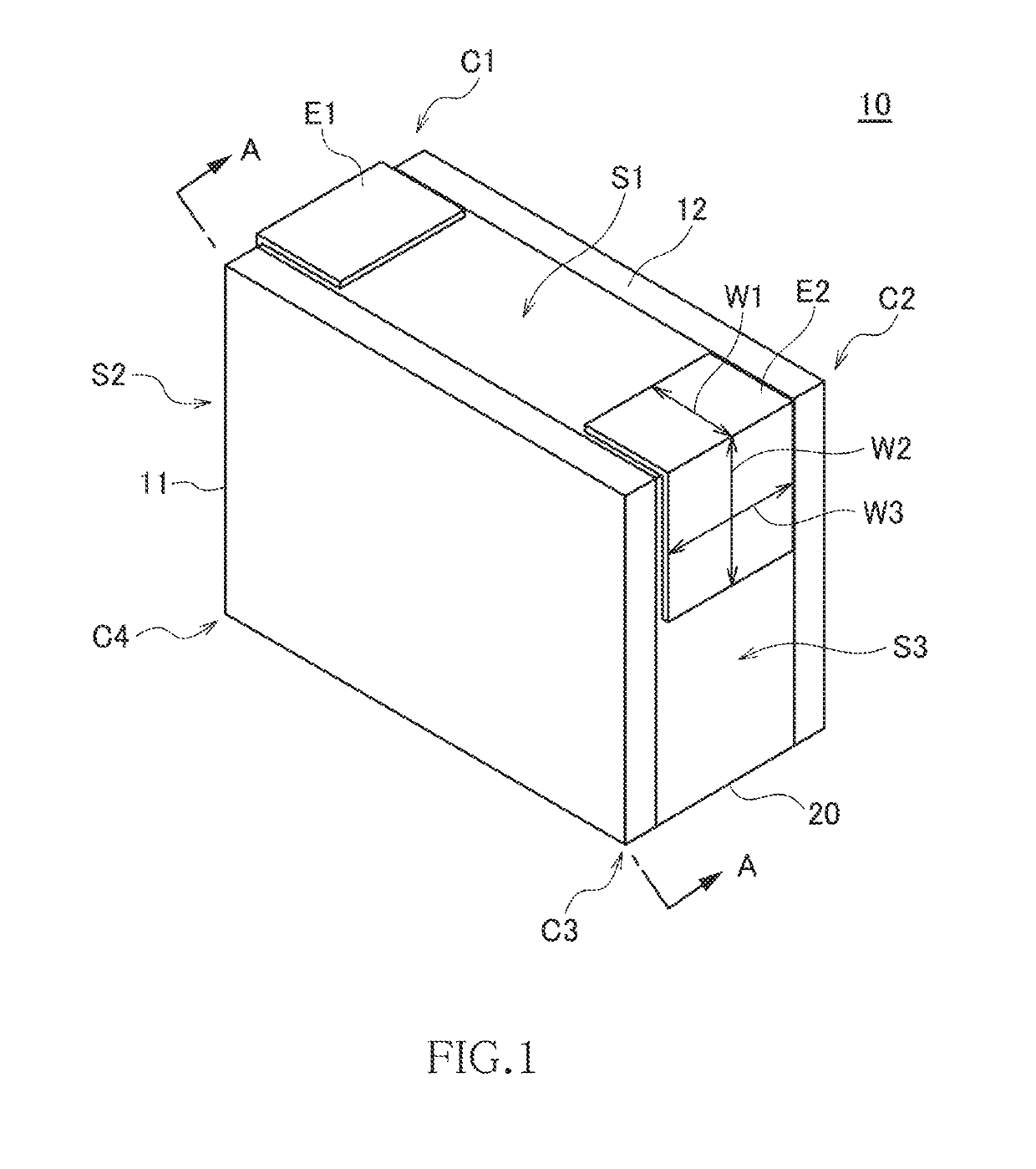

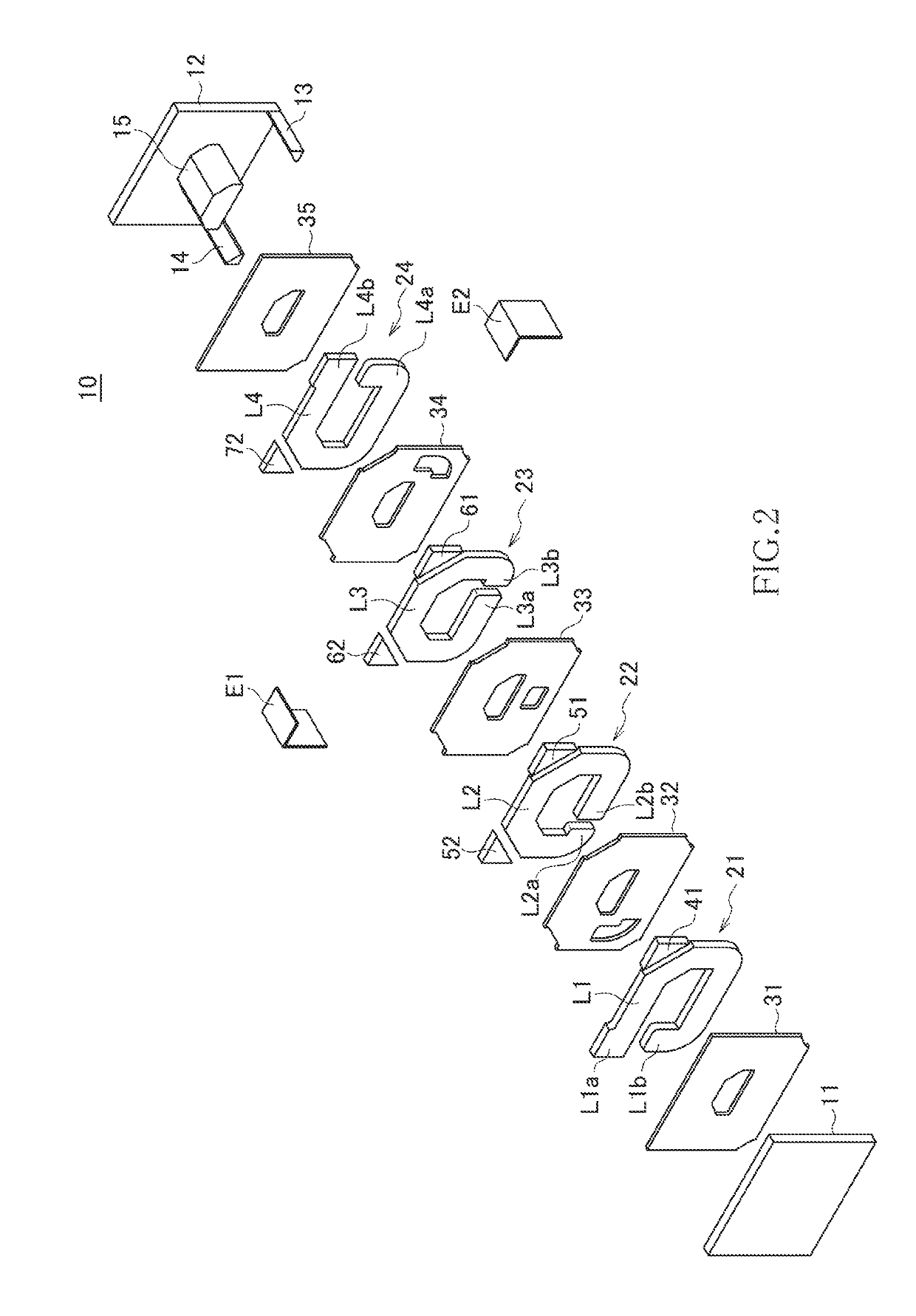

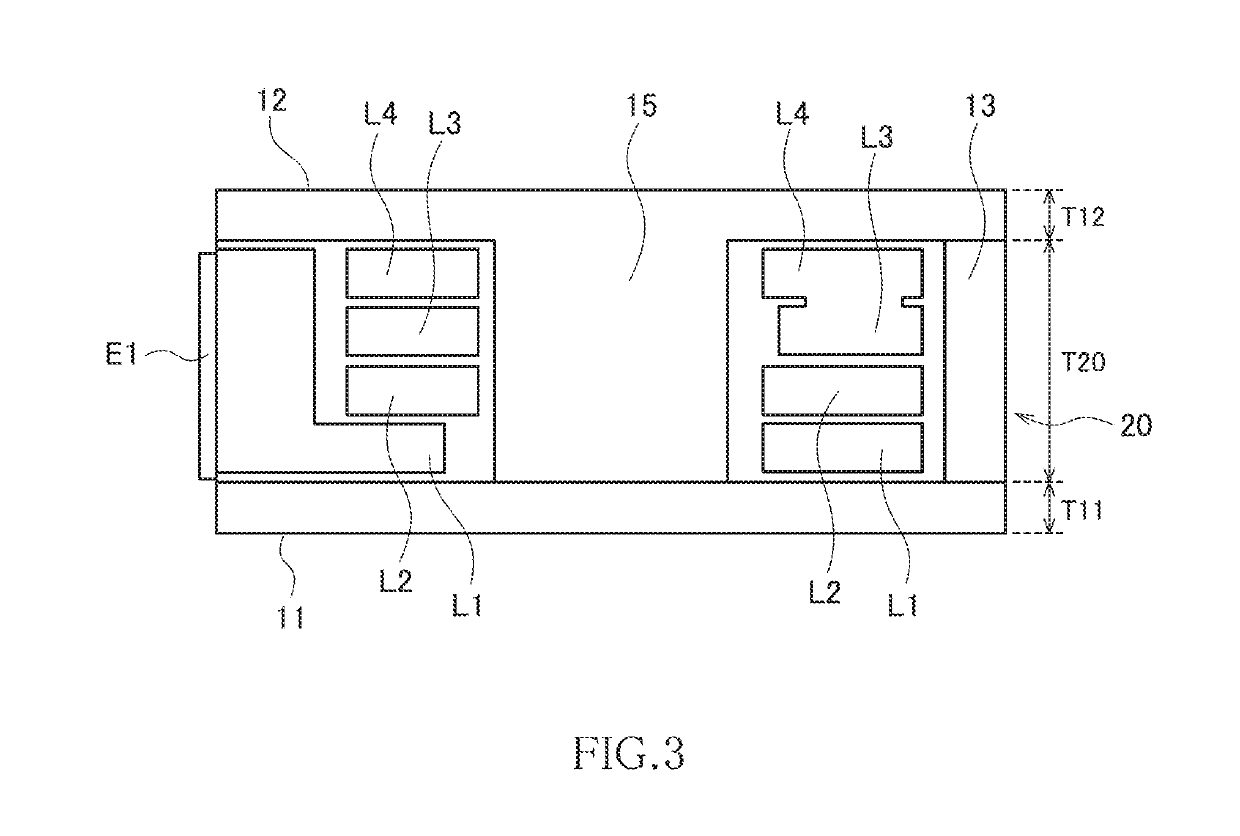

[0034]FIG. 1 is a perspective view illustrating the outer appearance of a coil component 10 according to a preferred embodiment of the present invention. FIG. 2 is an exploded perspective view of the coil component 10. FIG. 3 is a cross-sectional view taken along the line A-A illustrated in FIG. 1.

[0035]The coil component 10 according to the present embodiment is a surface-mount type chip component that can be used as an inductor for a power supply circuit. As illustrated in FIGS. 1 to 3, the coil component 10 includes first and second magnetic members 11 and 12 and a coil layer 20 sandwiched between the first and second magnetic members 11 and 12.

[0036]The magnetic member 11 is a substrate made of a magnetic material such as a ferrite. As described later, in the manufacturing process of the coil component 10, the magnetic member 11 is used as a substrate, and the coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| switching frequency | aaaaa | aaaaa |

| non-magnetic | aaaaa | aaaaa |

| magnetic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com