Fluoroelastomer, production thereof, crosslinkable composition and curing product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

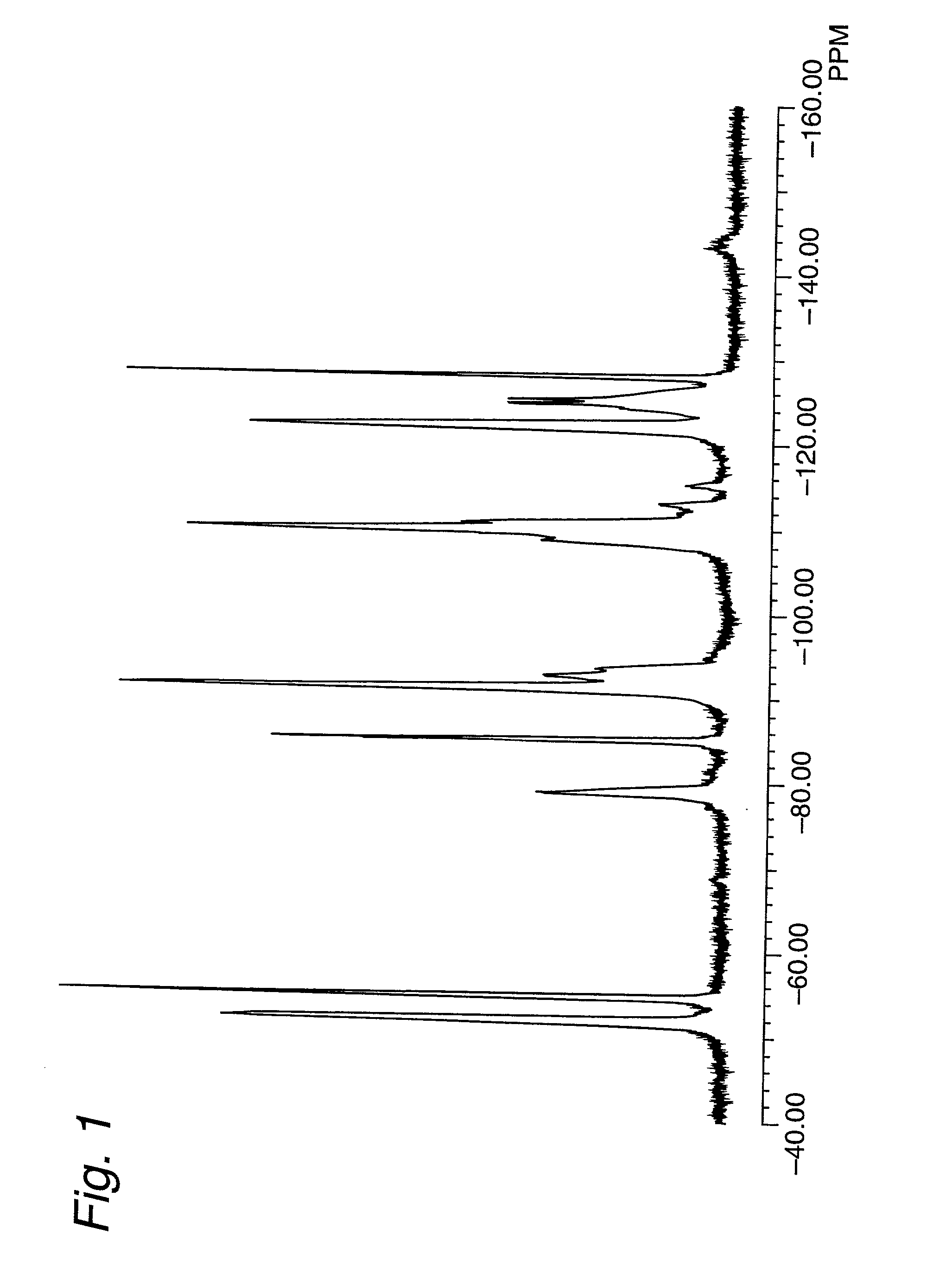

Image

Examples

example 1

[0084] A 500 ml autoclave was charged with:

[0085] 44 g (69.3 mol %) of vinylidene fluoride (VdF),

[0086] 6 g (6.1 mol %) of tetrafluoroethylene (TFE),

[0087] 24 g (14.6 mol %) of perfluoro(methyl vinyl ether)

[0088] (FMVE) and 32 g (10.0 mol %) of perfluoro(methoxypropyl vinyl ether) (MPVE),

[0089] 5 g of ammonium perfluorooctanoate,

[0090] 0.54 g of Na.sub.2HPO.sub.4.multidot.12H.sub.2O,

[0091] 0.02 g of NaHSO.sub.3,

[0092] 200 ml of water, and

[0093] 1.0 g of CF.sub.2.dbd.CFOCF.sub.2CF.sub.2Br.

[0094] The mixture was heated to 50.degree. C., and 0.1 g of ammonium persulfate was added thereto to thereby initiate a polymerization. The reaction was performed for 8 hr, and the mixture was cooled to about 30.degree. C. Unreacted gas was released, and the polymerization was terminated.

[0095] The obtained product was subjected to salting out with the use of a 2% aqueous solution of calcium chloride, and dried. Thus, there was obtained 100.6 g (polymerization ratio: 94.0%) of white fluoroelastomer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Substance count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com