Handheld type four-cycle engine

a four-cycle engine, handheld technology, applied in machine/engine, valve drive, auxillary lubrication, etc., can solve the problems of increasing the size of the engine main body, difficult to reduce the weight, and comparatively long and complicated circulation routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

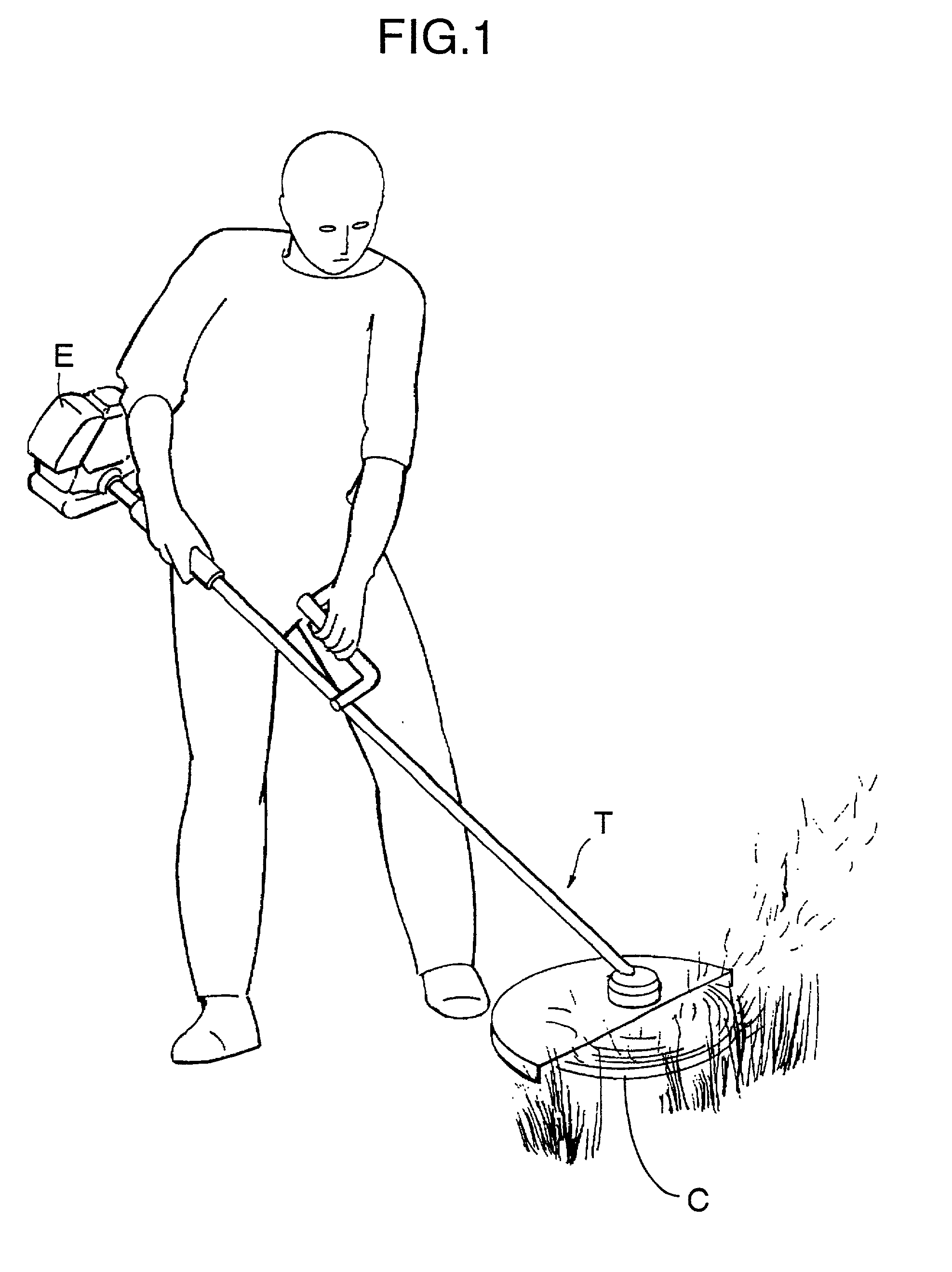

[0028] As shown in FIG. 1, a handheld type four-cycle engine E to which the present invention is applied is fitted as the source of power to the driving section of, for example, a powered trimmer T. Since the powered trimmer T is used in a manner in which a cutter C is positioned in various directions according to the operational conditions, the engine E is also tilted to a large extent or turned upside-down as a result, and the operational position is unstable.

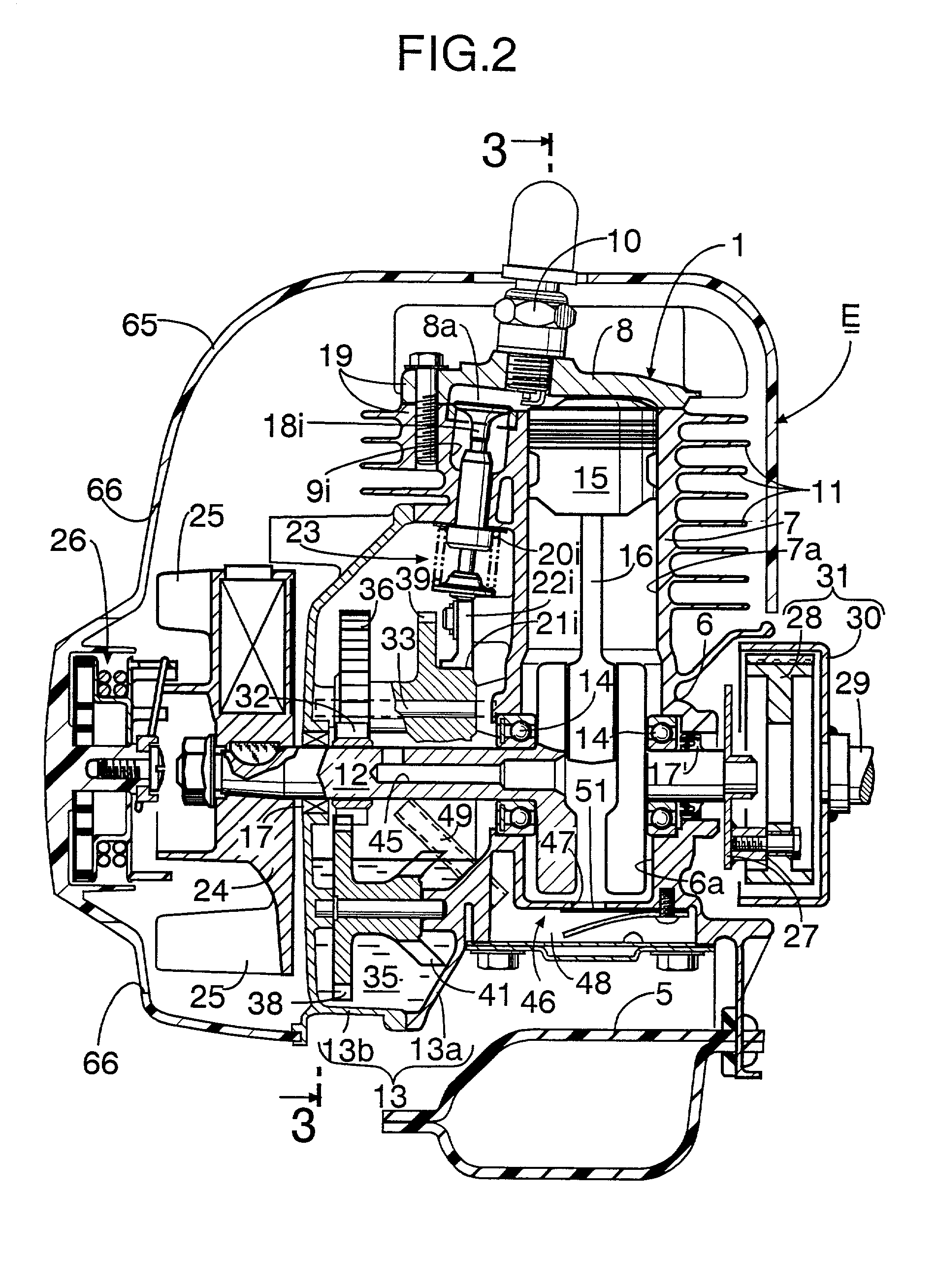

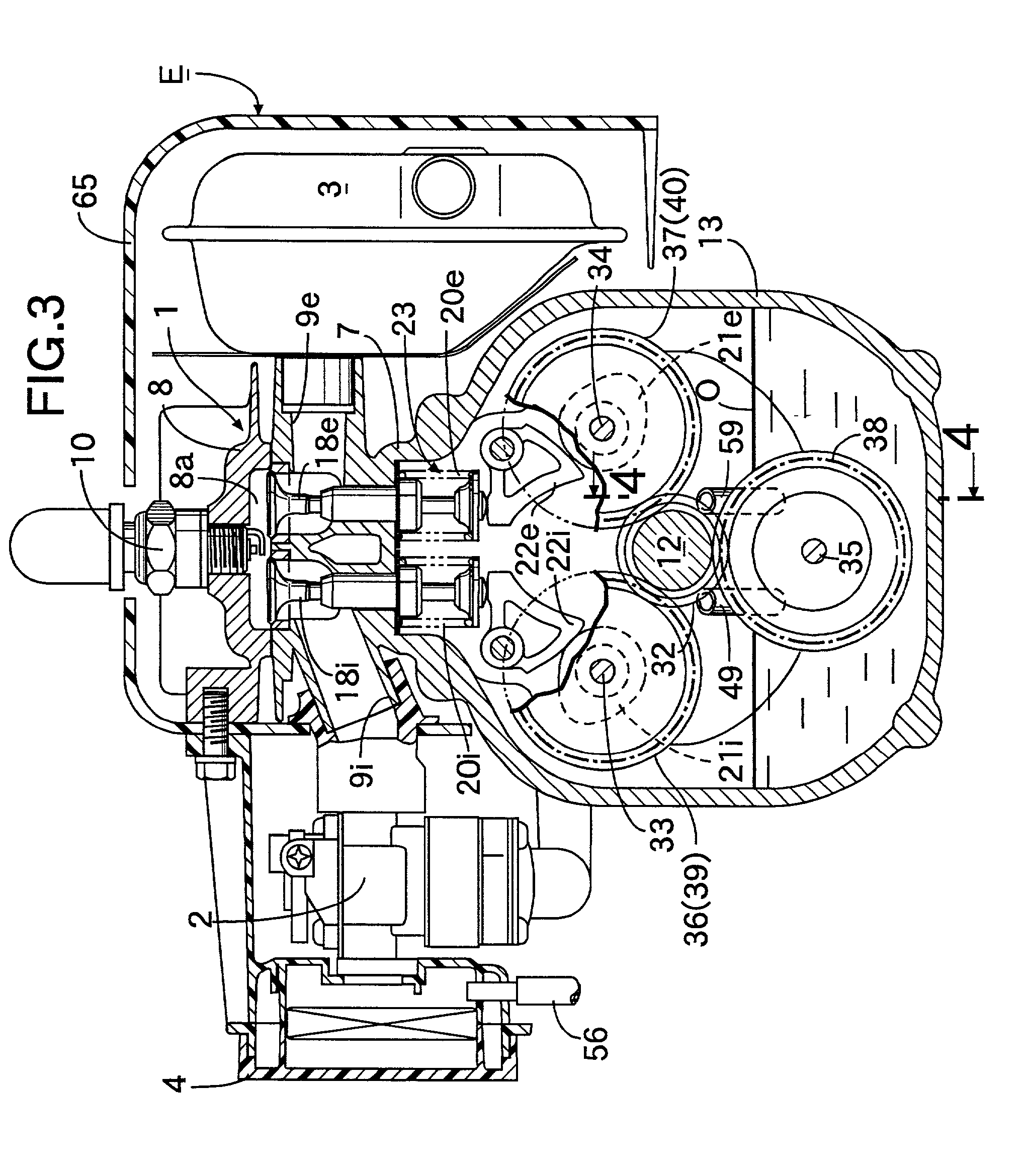

[0029] As shown in FIGS. 2 and 3, the engine main body 1 of the above-mentioned handheld type four-cycle engine E includes a crankcase 6 having a crank chamber 6a, a cylinder block 7 having one cylinder bore 7a, and a cylinder head 8 having a combustion chamber 8a, and a large number of cooling fins 11 are formed on the outer peripheries of the cylinder block 7 and the cylinder head 8.

[0030] The crankshaft 12 housed in the crank chamber 6a is supported in right and left side walls of the crankcase 6 in a rotatable manner via ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com