Film-forming apparatus, method of cleaning the same, and method of manufacturing a light-emitting device

a film-forming apparatus and film-forming technology, applied in the direction of spray discharge apparatus, vacuum evaporation coating, coating, etc., can solve the problems of reducing throughput and inability to subject organic el materials to photolithography after

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 1

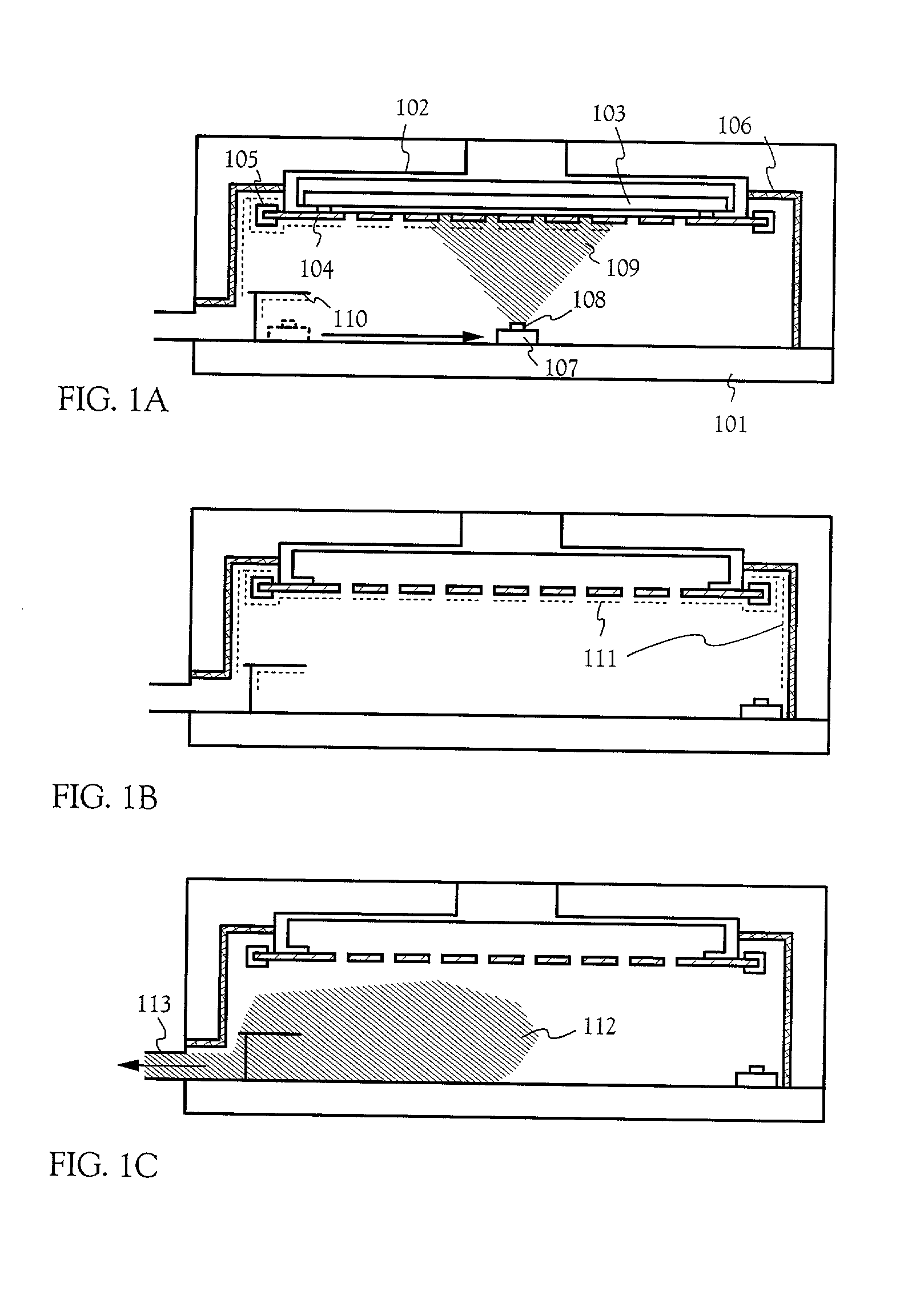

[0039] In this embodiment, a method of cleaning a film-forming apparatus will be described, which is characterized in that equipments provided in a film-forming apparatus are irradiated with infrared light, UV-light, or visible light to sublimate a vapor-deposition material adhering to the equipments, and the sublimated vapor-deposition material is exhausted. The present example is one example of the present invention, and can cite the above description.

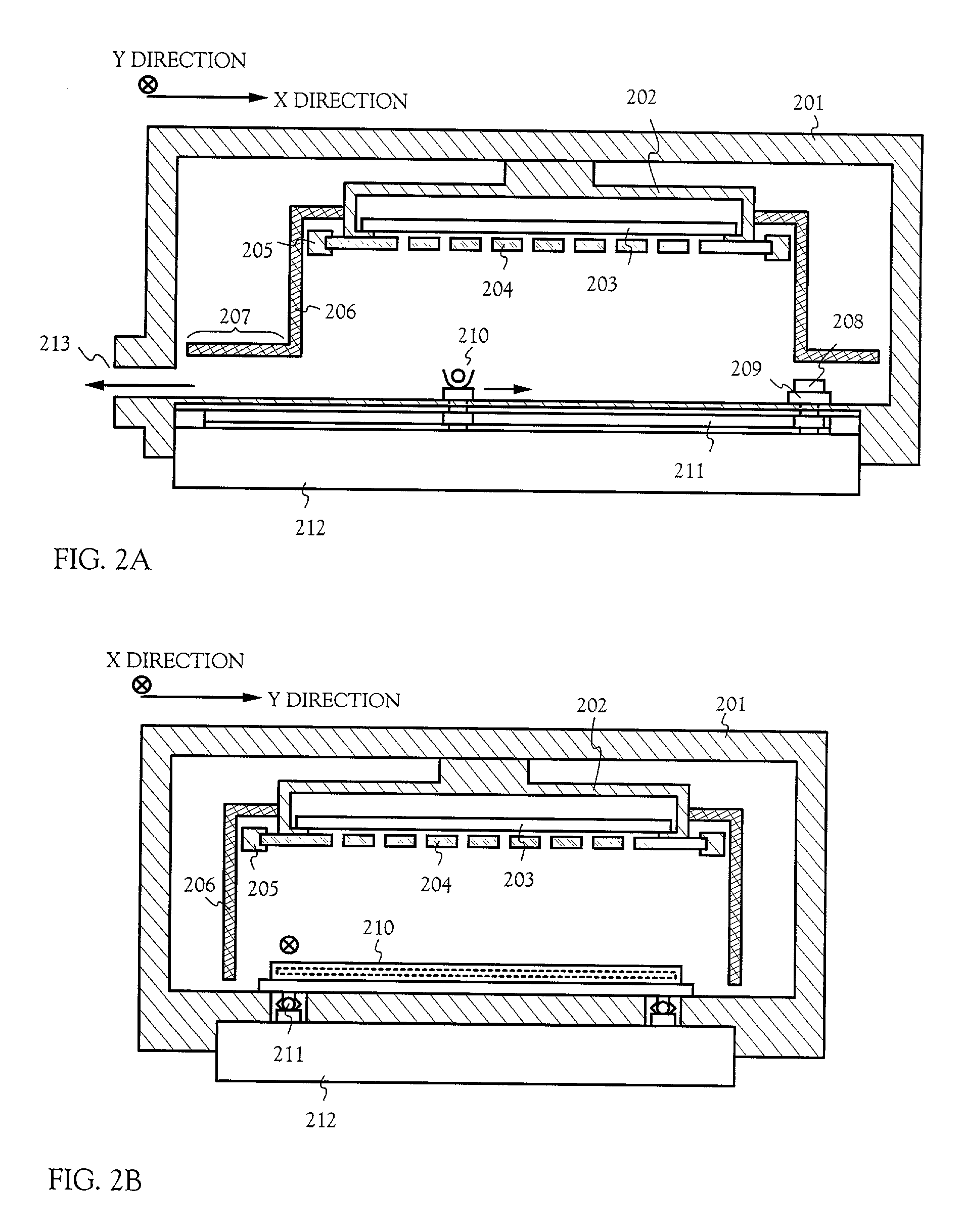

[0040] FIGS. 2A-2B show cross-sectional structures of a film-forming portion in a film-forming apparatus of this embodiment. FIGS. 2A and 2B show cross-sectional structures taken in directions vertical to each other. FIG. 2A shows a cross-section in an X-direction, and FIG. 2B shows a cross-section in a Y-direction. FIG. 4 is a top view of the film-forming portion in the film-forming apparatus of this embodiment.

[0041] In FIGS. 2A and 2B, a substrate holder 202 is provided in a film-forming chamber 201, and a substrate 203 is support...

embodiment 2

[0053] In this embodiment, a method of cleaning a film-forming apparatus will be described, which is characterized in that equipments provided in a film-forming chamber are heated with radiation heat to sublimate a vapor-deposition material adhering to the equipments, and the sublimated vapor-deposition material is exhausted. Radiation heat may be generated by flowing a current through a metal line (typically, a nichrome line) with high electrical resistance. Further, this embodiment is one example of the present invention, and can cite the above description.

[0054] FIGS. 5A-5B show cross-sectional structures of a film-forming portion in a film-forming apparatus of this embodiment. FIGS. 5A and 5B show cross-sectional structures taken in directions vertical to each other. FIG. 5A shows a cross-section in an X-direction, and FIG. 5B shows a cross-section in a Y-direction. Further, FIG. 6 is a top view of the film-forming portion in the film-forming apparatus of this embodiment.

[0055] ...

embodiment 3

[0064] In this embodiment, a film-forming apparatus will be described in which an exhaust treatment chamber is connected to a film-forming chamber. In the film-forming apparatus of this embodiment shown in FIG. 7, a film-forming chamber 702 has the same structure as that shown in FIG. 2A, and an exhaust treatment chamber 701 is connected in series to the film-forming chamber 702. Thus, regarding the film-forming chamber 702, Embodiment 1 will be referred to, and the exhaust treatment chamber 701 will be mainly described.

[0065] In FIG. 7, the exhaust treatment chamber 701 is connected to the film-forming chamber 702 through a gate 703. The gate 703 plays a role in preventing exhaust gas from being mixed in the film-forming chamber 702 from the exhaust treatment chamber 701. Heating wires 704 are provided at a pipe in the vicinity of the gate 703, and the pipe 705 can be heated. The heating wires 704 are provided so as to prevent the vapor-deposition material exhausted from the film-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com