Organic electroluminescent device with improved hole injecting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Fabrication Procedure

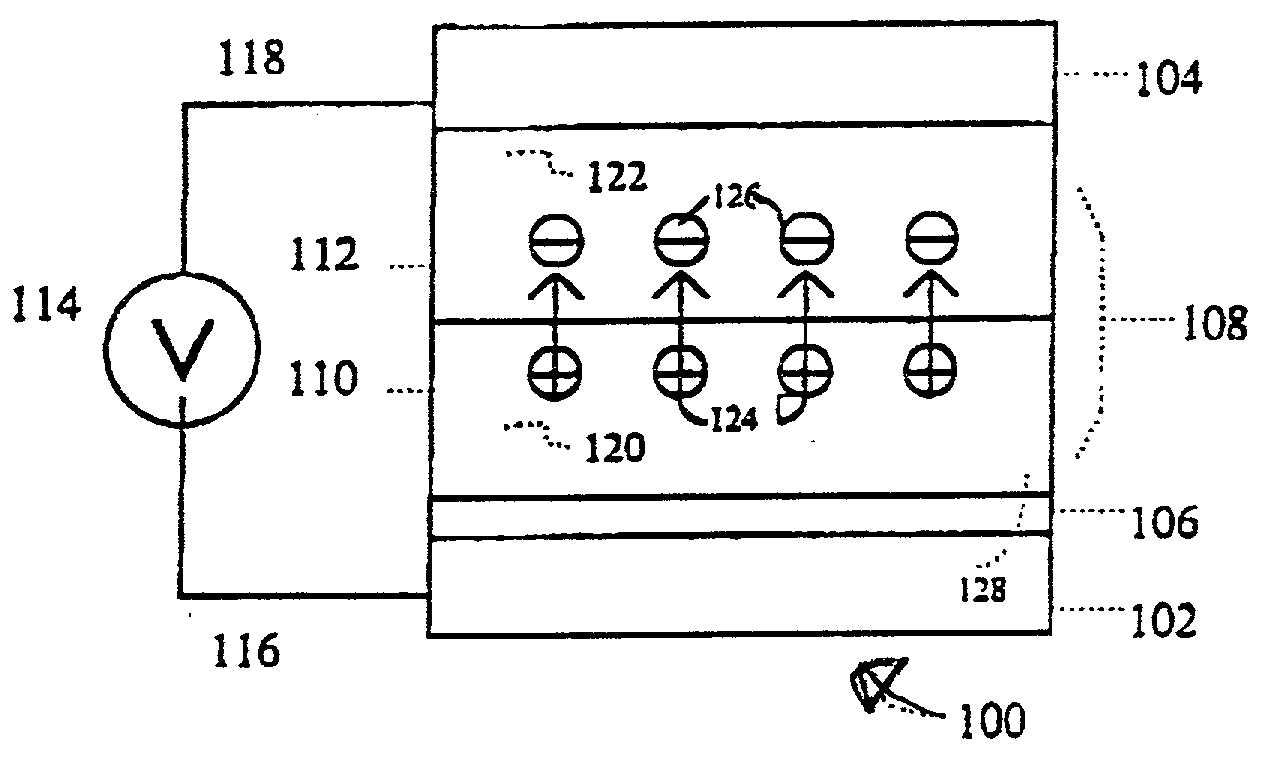

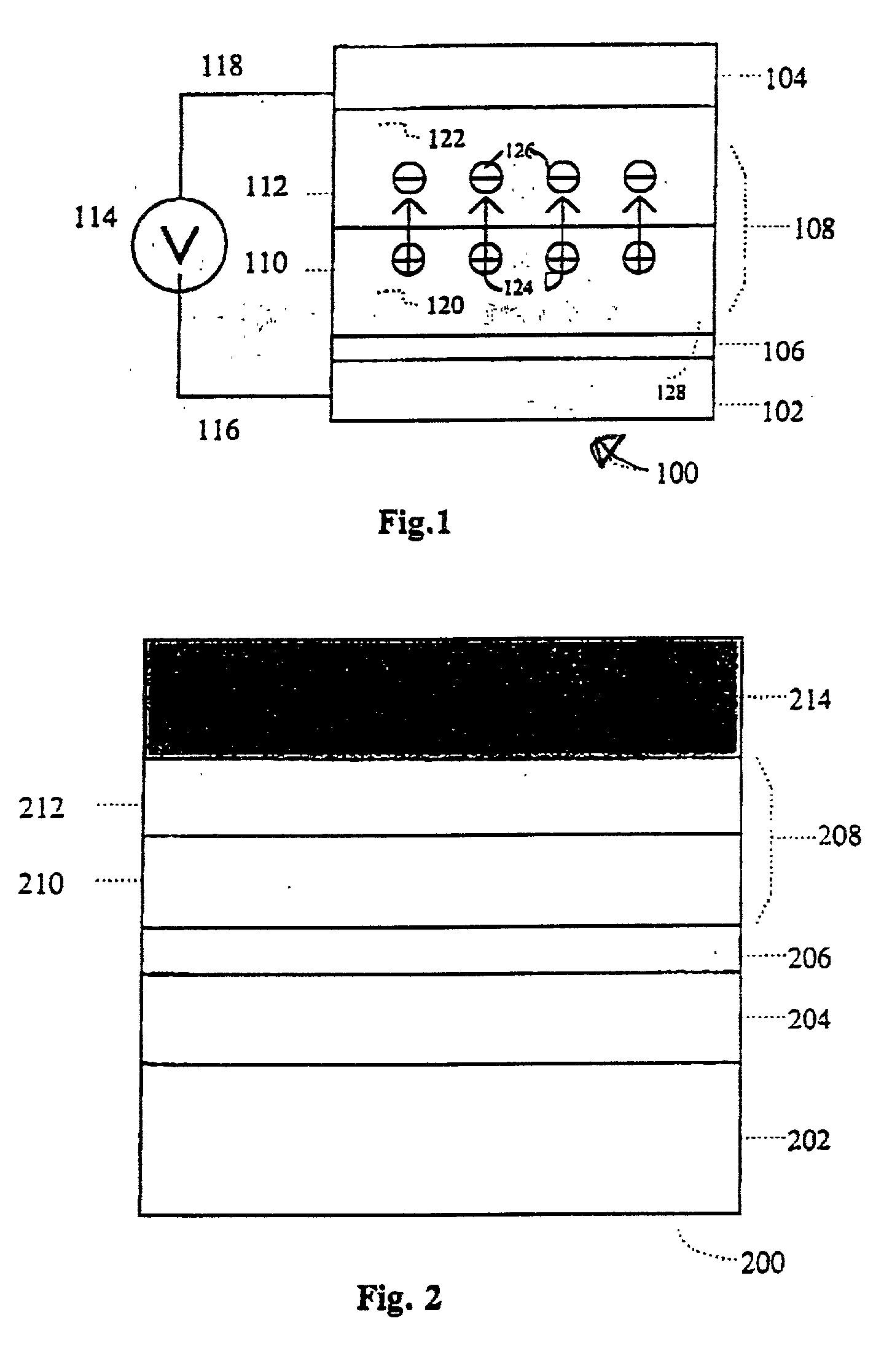

[0023] An OELD satisfying the requirements of the invention was constructed in the following manner. The device structure has an inorganic buffer layer and a two organic-layer stack, namely hole transporting layer and fluorescent emitting and electron transporting layer.

[0024] An indium-tin-oxide coated glass substrate was sequentially ultrasonicated in a commercial detergent, rinsed in deionized water, degreased in organic solvent, such as ethanol and acetone, and exposed to ultraviolet light and ozone for a few minutes.

[0025] An inorganic buffer layer (0-200 Angstroms) was then deposited on top of the ITO coated substrate by evaporation.

[0026] Onto the buffer layer was deposited a hole transporting layer of TPD or NPB (500-1,500 Angstroms), evaporated from a tantalum boat.

[0027] A fluorescent emitting and electron transporting layer of Alq (600 Angstroms) was then deposited onto the hole transporting layer.

[0028] On top of the Alq layer was deposited a ...

example 2

[0030] OELDs with SiO.sub.2 Buffer Layer

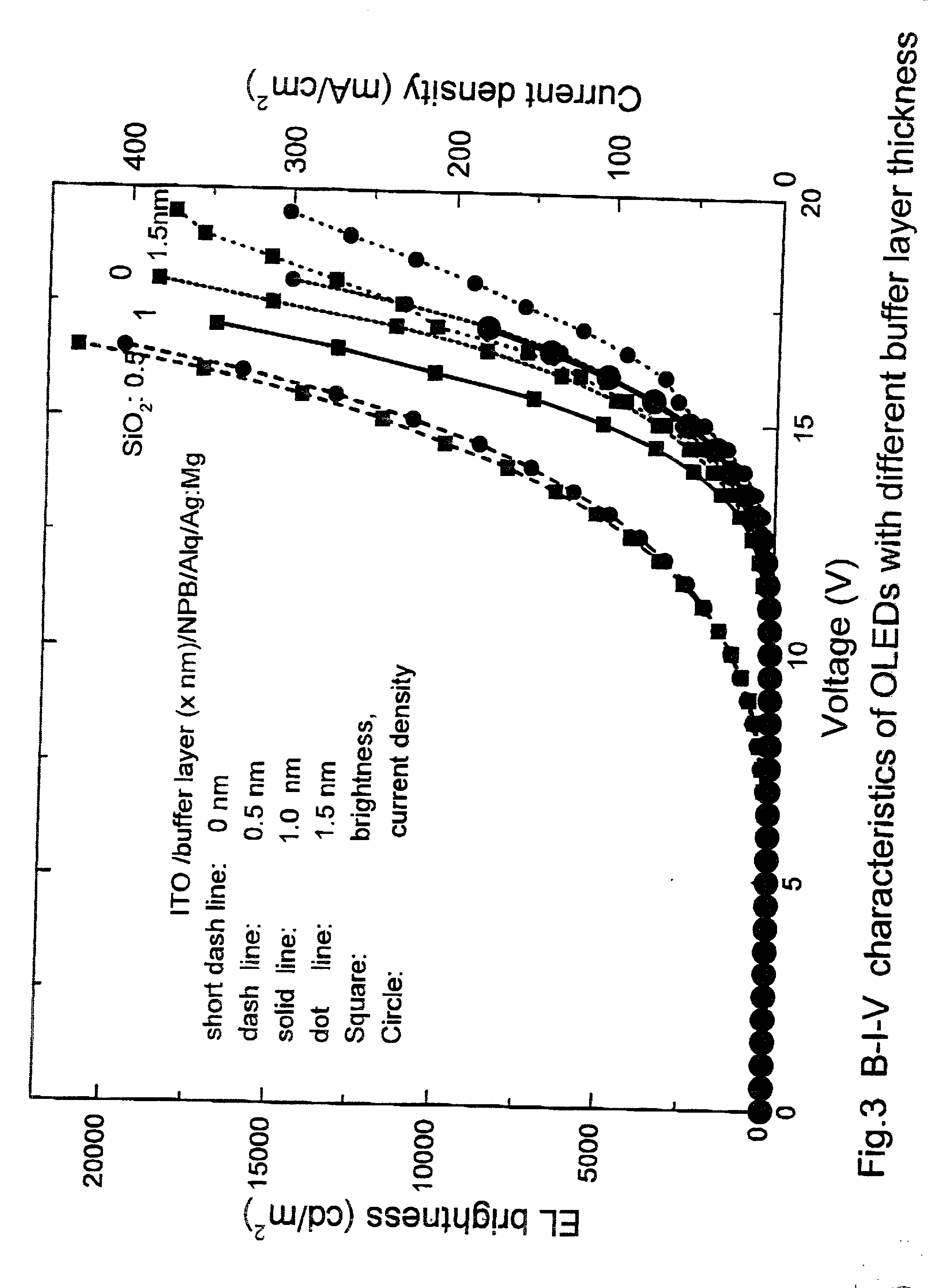

[0031] The OELDs were fabricated according to the procedure of Example 1. The buffer layers with different thicknesses of SiO.sub.2 were used. Table 1 lists the EL luminance quantum efficiency measured in unit of candela per ampere, and luminance output under a constant current bias of 20 mA / cm.sup.2.

1TABLE 1 SiO.sub.2 Thickness (nm) 0 0.5 1.0 1.5 CIEx 0.334 0.338 0.339 0.339 CIEy 0.562 0.563 0.562 0.562 Luminance 1,140 960 1,820 1,680 Luminance Eff. (cd / A) 5.7 4.8 9.1 8.4

[0032] Referring to the luminance efficiency, it can be observed that there may be a reduction in efficiency with a particularly thin layer. However, as shown in this example using SiO.sub.2, the efficiency increases towards the thickness of 1 nm. There may then be a tailing off of efficiency as the thickness increases. This particular buffer layer is an insulating layer and will inhibit current as the layer thickness increases. The thickness as provided in this table shows t...

example 3

[0033] Brightness-Current-Voltage (B-I-V) Characteristics

[0034] The OELDs were fabricated according to the procedure of Example 1. FIG. 3 shows the B-I-V curves of four devices with different thicknesses of buffer layer (SiO.sub.2)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com