Organic compound, polymer, organic mixture, composition and organic electronic device

A technology of organic compounds and organic mixtures, which is applied in the fields of organic electronic devices, organic mixtures, compositions, organic compounds, and polymers, and can solve problems such as different carrier transport rates, shortened device life, and roll-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

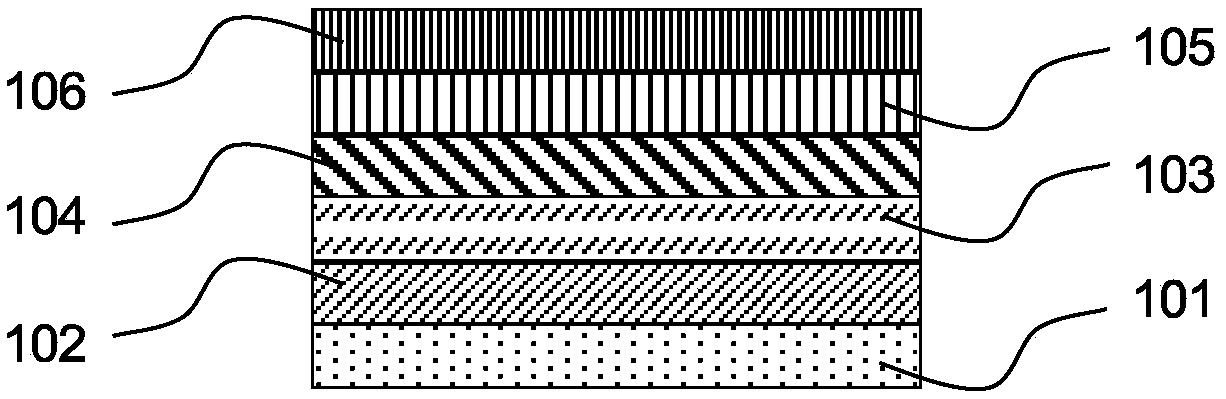

[0220] An embodiment of a method for preparing an organic electronic device includes forming a functional layer on a substrate by vapor deposition of an organic compound or an organic mixture, and co-evaporating the organic compound and organic functional material on a substrate To form a functional layer, to form a functional layer on a substrate by co-evaporating the organic mixture with organic functional materials, and to coat the composition on a substrate by printing or coating to form a functional layer. One kind.

[0221] Specifically, the printing or coating method is selected from one of the following methods, but not limited to the following methods: inkjet printing, nozzle printing, letterpress printing, screen printing, dip coating, spin coating, doctor blade Coating, roller printing, twisting roller printing, offset printing, flexographic printing, rotary printing, spraying, brushing, pad printing and slit extrusion coating, etc.

[0222] Further, the composition is ...

Embodiment 1

[0242]

[0243] (1) Synthesis of compound 1-1

[0244] The compound 10H-spiro[吖-9,9'-fluorene] (16.55g, 50mmol) and 4-bromo-2-chloro-1-fluorobenzene (10.50g, 50mmol) were added to a three-necked flask, with 200mL of N, N-Dimethylformamide (DMF) is stirred and dissolved, protected by nitrogen, then Cs is added 2 CO 3 (19.5g, 60mmol) and K 2 CO 3 . The reaction solution was stirred and refluxed for 12 hours and cooled. The reaction solution was poured into 1000 mL of water and filtered with suction. The filter cake was washed with a mixed solvent of ethanol and petroleum ether and filtered with suction. The filter cake was used with a mixed solvent of dichloromethane and petroleum ether ( DCM / PE) was recrystallized to obtain compound 1-1 (16.09 g, yield 62%) as a white solid.

[0245] (2) Synthesis of compound 1-2

[0246] Add compound 1-1 (15.57g, 30mmol) and 9-phenyl-carbazole-3-boronic acid (8.61g, 30mmol) into a three-necked flask, stir to dissolve with 200mL of toluene, protect ...

Embodiment 2

[0250]

[0251] (1) Synthesis of compound 2-1

[0252] Add compound 1-1 (10.38g, 20mmol) and 9-(1.1) biphenyl-carbazole-3-boronic acid (7.26g, 20mmol) into a three-necked flask, stir to dissolve with 200mL of toluene, protect with nitrogen, and then add four (Triphenylphosphine) Palladium (Pd(PPh 3 ) 4 ) (1.13g, 1mmol) and K 2 CO 3 (5.52g, 40mmol). The reaction solution was stirred and refluxed for 12 hours, cooled, and then washed three times with 100 mL of water, dried with anhydrous sodium sulfate, and evaporated to remove the solvent. The residue was purified by column with DCM / PE (1:15) to obtain a white solid, compound 2-1 (8.95g, yield 59%).

[0253] (2) Synthesis of compound 2

[0254] Compound 2-1 (7.59g, 10mmol) and K 2 CO 3 (2.76g, 20mmol) was added to a three-necked flask, stirred with 100mL DMA to dissolve, protected by nitrogen, and then added Pd(dba) 2 (278 mg, 0.5 mmol) and tricyclohexylphosphine tetrafluorophenylboronic acid (368 mg, 1 mmol). The reaction solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com