Head supporting device and disk drive using the same

a technology of supporting device and disk drive, which is applied in the field of supporting device, can solve the problems of slider jumping off the magnetic recording medium, affecting the operation reducing the amount of so as to achieve even faster rotational movement and reduce the effect of undesired vibration of the support arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

[0071] As a first exemplary embodiment, an operating principle of a head supporting device of the present invention will be described first, using a magnetic disk drive as an example.

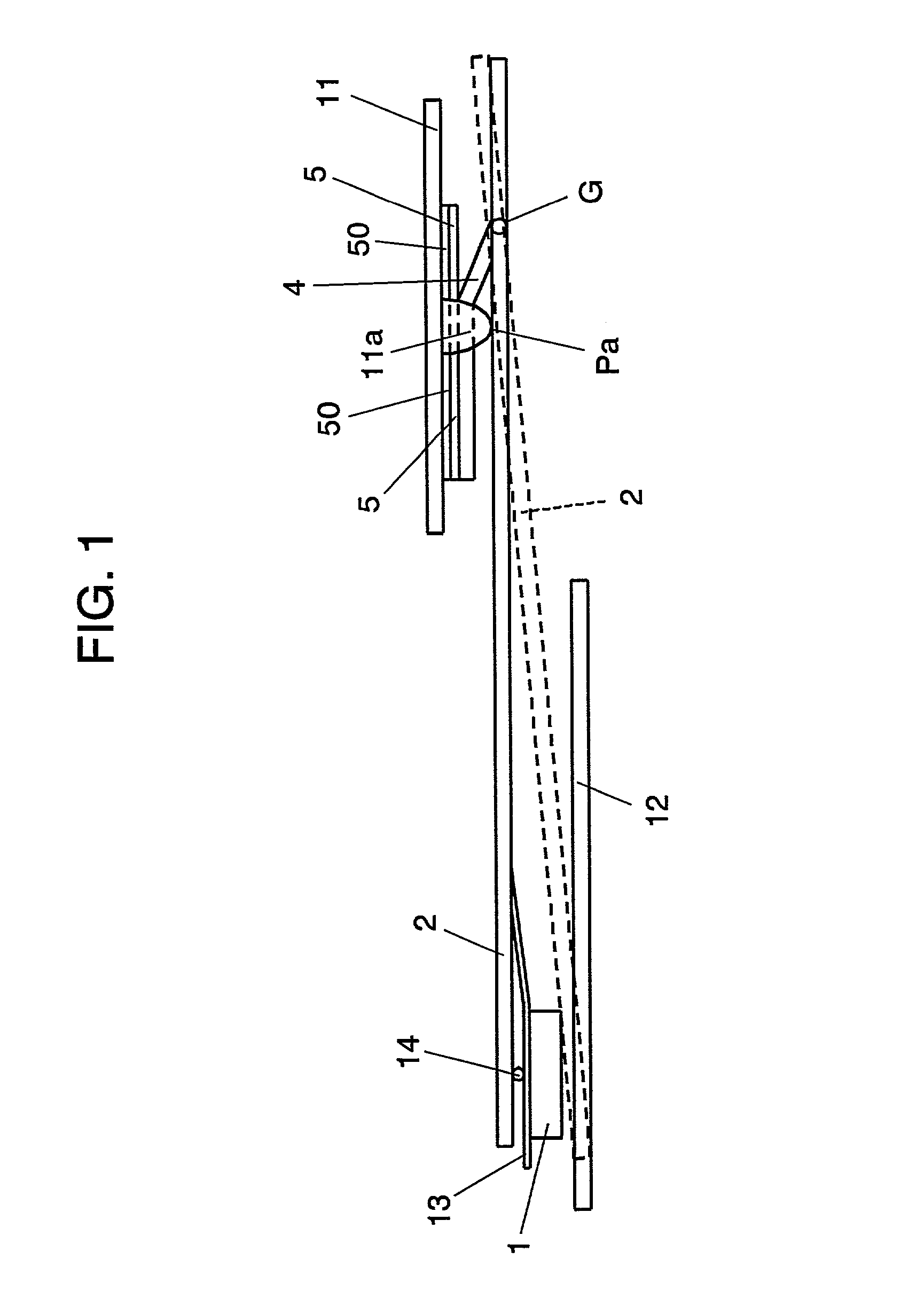

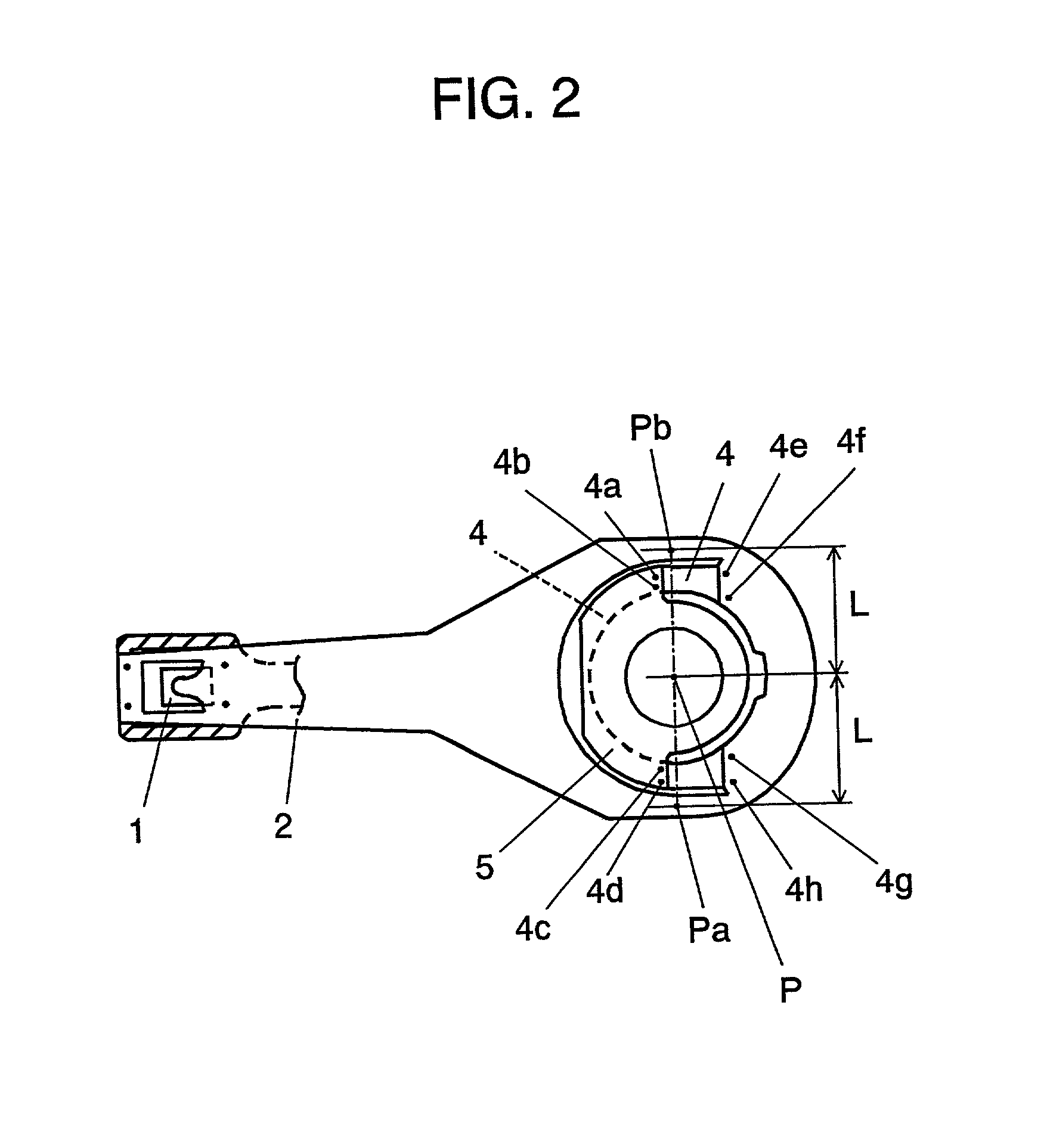

[0072] FIG. 1 is a side view depicting a general structure of a head supporting device, for the purpose of showing the operating principle of the head supporting device of this invention, FIG. 2 is a plan view, and FIG. 3 is an exploded structural illustration of the same.

[0073] In FIG. 1 and FIG. 2, slider 1 provided with a magnetic head (not show in the figures) on an underside surface thereof is mounted to an underside surface at one end of support arm 2, which is then fixed at the other end to one end portion of plate spring 4, as shown in the figures. The other end portion of the plate spring 4 is fixed to spring fixation member 5, which in turn is fixed to pivot pedestal 11 through spacer 50.

[0074] Accordingly, the support arm 2 is now in a configuration that it is flexibly secured to the pivot pe...

second exemplary embodiment

[0094] A structure of the head supporting device of this invention that achieves the operating principle shown in the first exemplary embodiment will be disclosed next as a second exemplary embodiment of this invention.

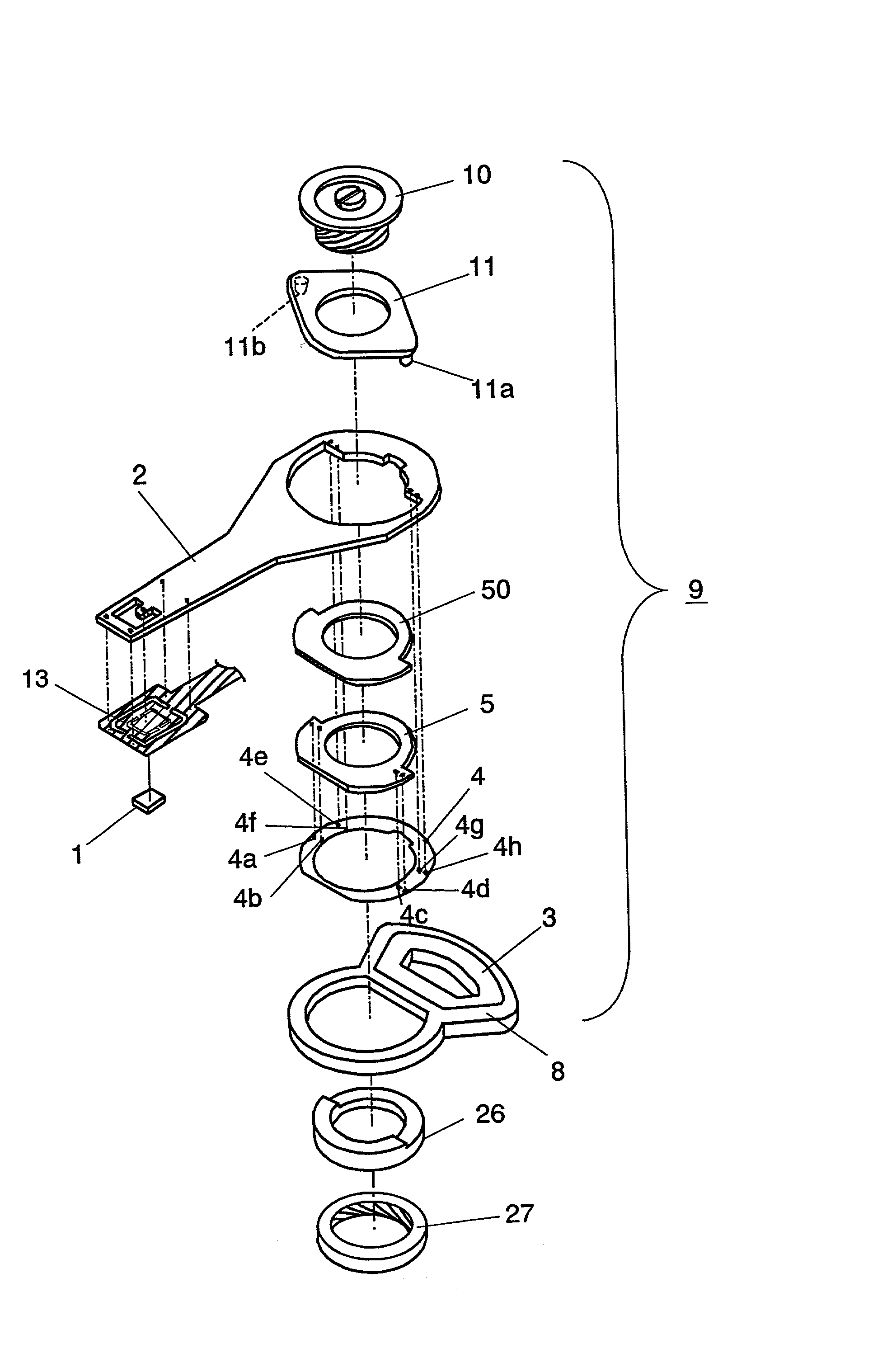

[0095] FIG. 3 is an exploded perspective view depicting the structure of the head supporting device of this invention, FIG. 4 is also an exploded perspective view, and FIG. 5 is a side view showing a main portion in the vicinity of a bearing unit of the same.

[0096] In the head supporting device 9, plate spring 4 of an annular shape and spring fixation member 5 also of an annular shape are connected by welding at points 4a, 4b, 4c and 4d, as shown in FIG. 3 and FIG. 4. Support arm 2 and the plate spring 4 are connected also by welding at points 4e, 4f, 4g and 4h. The support arm 2 is connected to coil holder 8 provided with coil 3, so as to be rotatable by a voice coil motor in a radial direction of magnetic recording medium 12. This structure is such that the above me...

third exemplary embodiment

[0119] Referring to the accompanying figures, a structure of a disk drive of this invention will be described using a magnetic disk drive as an example of the third exemplary embodiment. FIG. 6 is a plan view depicting a structure of magnetic disk drive 23 of the present invention, and FIG. 7 is a sectional view taken along a line A-A in FIG. 6.

[0120] A structure and operation of the magnetic disk drive of the invention and its head supporting device will be described first.

[0121] FIG. 6 and FIG. 7 illustrate the magnetic disk drive when it is not operating, i.e. in a state that a magnetic recording medium is not spinning.

[0122] Magnetic disk drive 23 of the present invention is provided with head supporting device 9 having support arm 2 formed unitary with a single material, as shown in FIG. 6 and FIG. 7.

[0123] The structure of the head supporting device 9 of the magnetic disk drive 23 of this invention is described hereinafter with reference to FIG. 6, FIG. 7 and FIG. 8. FIG. 8 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com