Water heater and water heater component construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

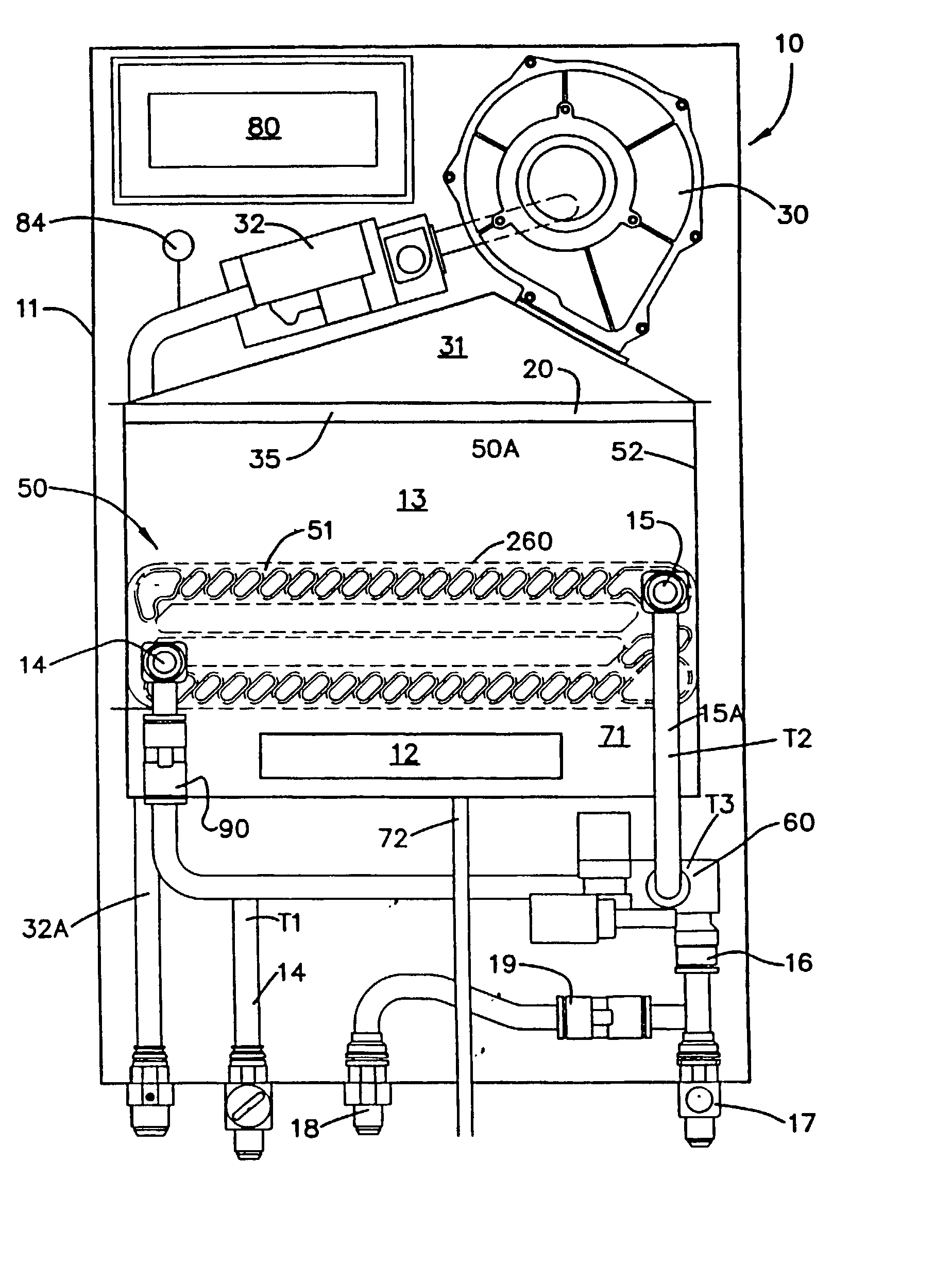

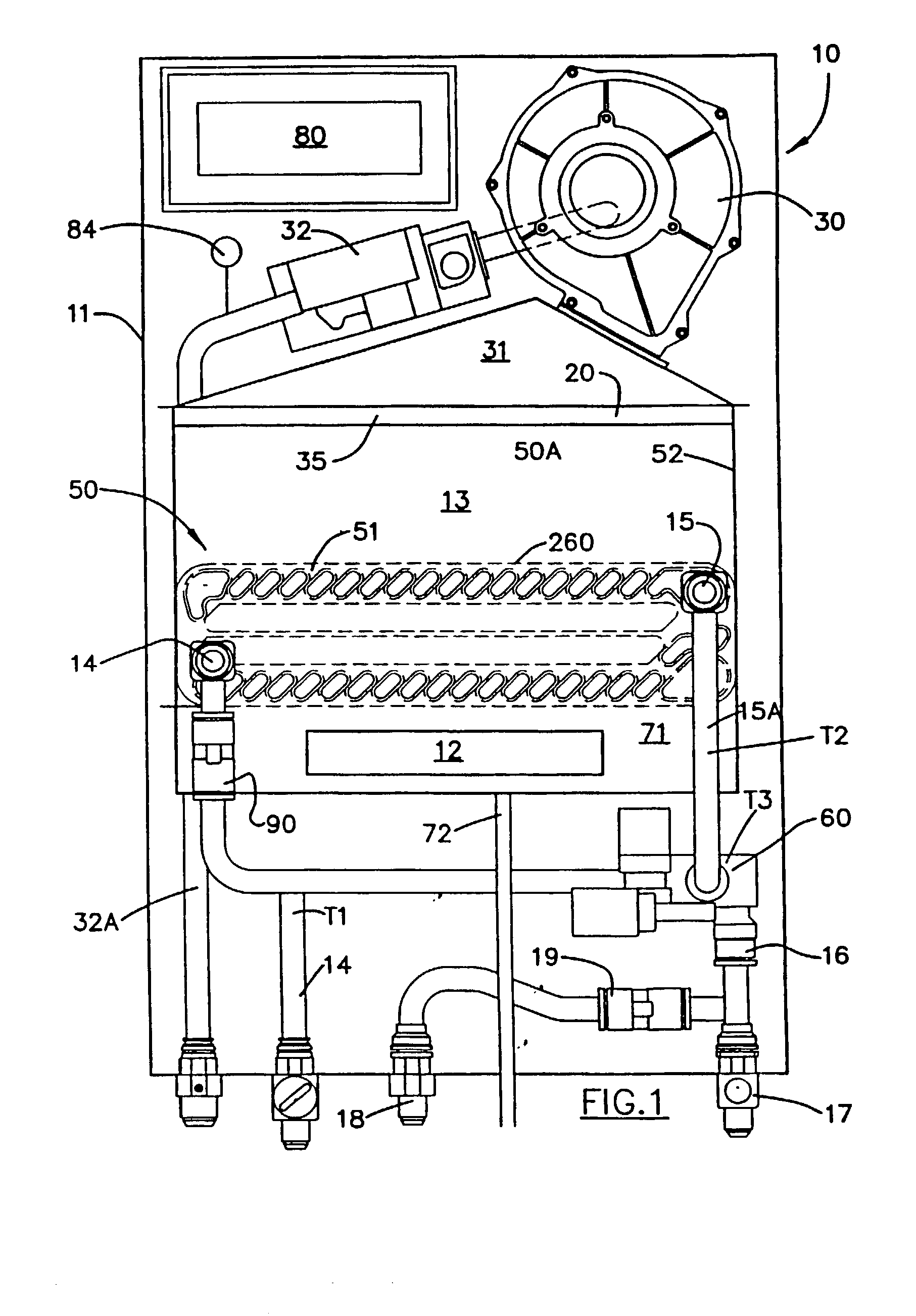

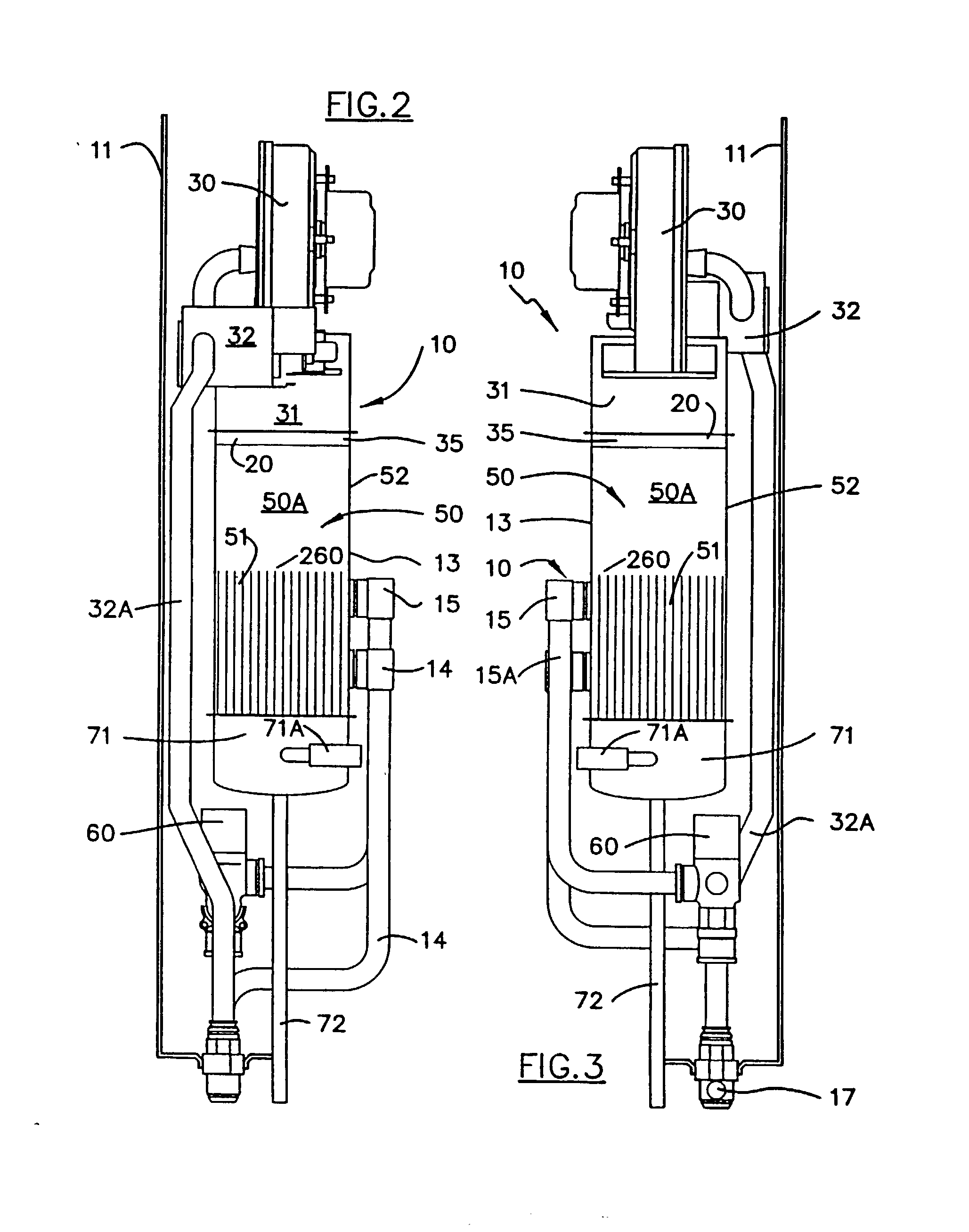

[0119] A domestic water heater 10 is illustrated in FIGS. 1 to 3, and is fuelled by gas and operates to provide an instantaneous flow of hot water.

[0120] As shown in FIGS. 1 to 3, the water heater 10 is housed in a rectangular enclosure 11 that is designed to be mounted flush against an external wall. The heater needs to be coupled to a supply of gas and it is understood that the heater can be adapted to work on a variety of commercially available gases. The combustion of the air gas mixture forms combustion products which are vented to the atmosphere via a small aperture 12 at the front 13 of the heater. Alternatively, the heater can be installed internally with exhaust gases being vented to the atmosphere via a small flue that would extend either through the wall cavity or up through the ceiling.

[0121] In summary, the water heater 10 has a burner 20 positioned above a water jacket assembly 50 so that heat and combustion products from the gas burner 20 pass through a heat exchanger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com