Method and installation for densifying porous substrates by chemical vapour infiltration

a technology of densification and chemical vapour, which is applied in the direction of chemical vapor deposition coating, coating, metallic material coating process, etc., can solve the problems of reducing the working volume available in the loading zone, reducing reducing the efficiency of the process. , to achieve the effect of improving the productivity of such ovens, without deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

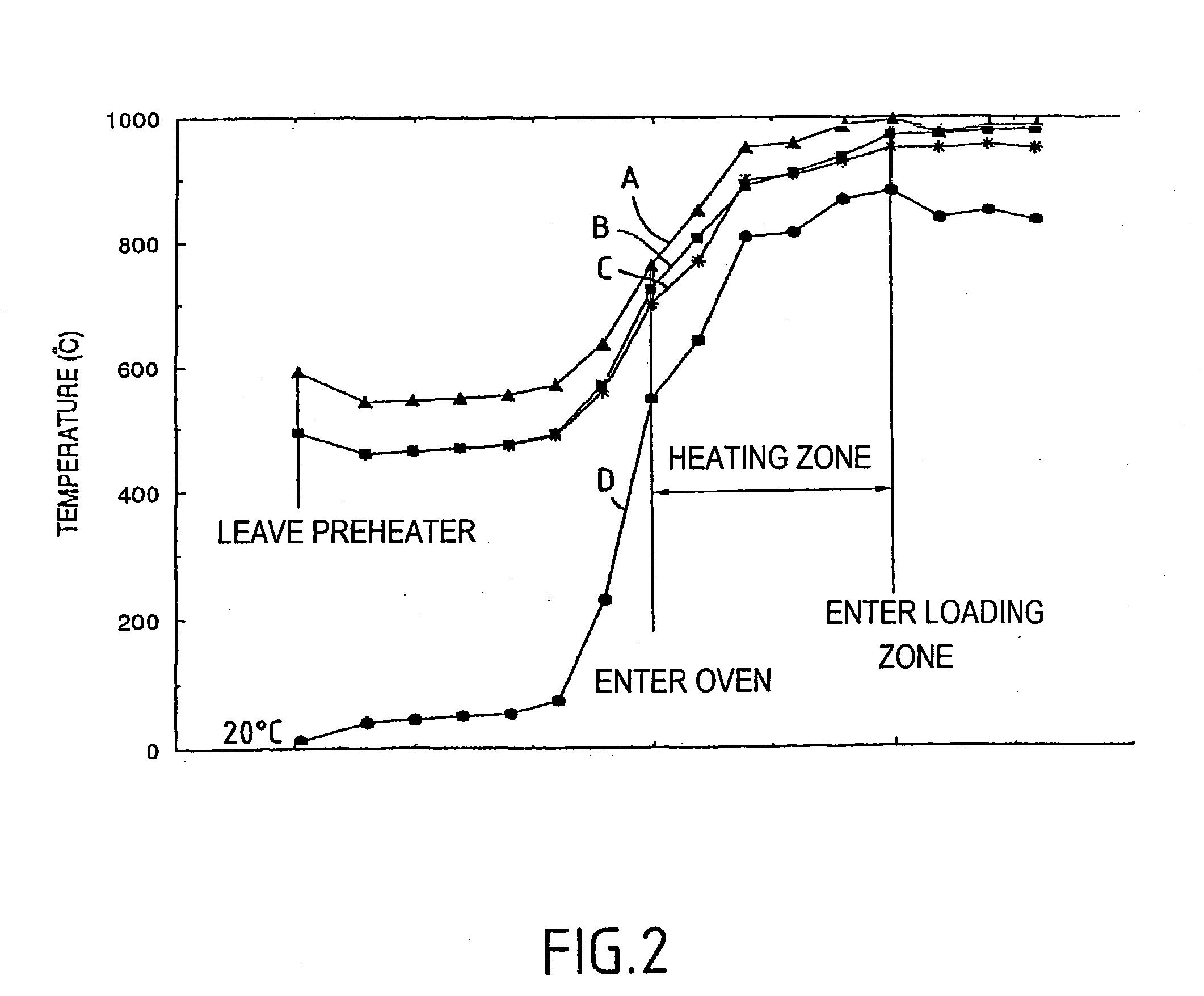

[0035] Implementations of the method and embodiments of the installation of the invention are described below in the context of an application to densifying annular porous substrates. The latter may constitute carbon fiber preforms or pre-densified blanks for making brake disks out of C / C composite material, the pre-densified blanks being obtained by pre-densification of performs by chemical vapour infiltration or by liquid (resin) impregnation followed by carbonization. Such brake disks are commonly used for aircraft landing gears and for racing cars.

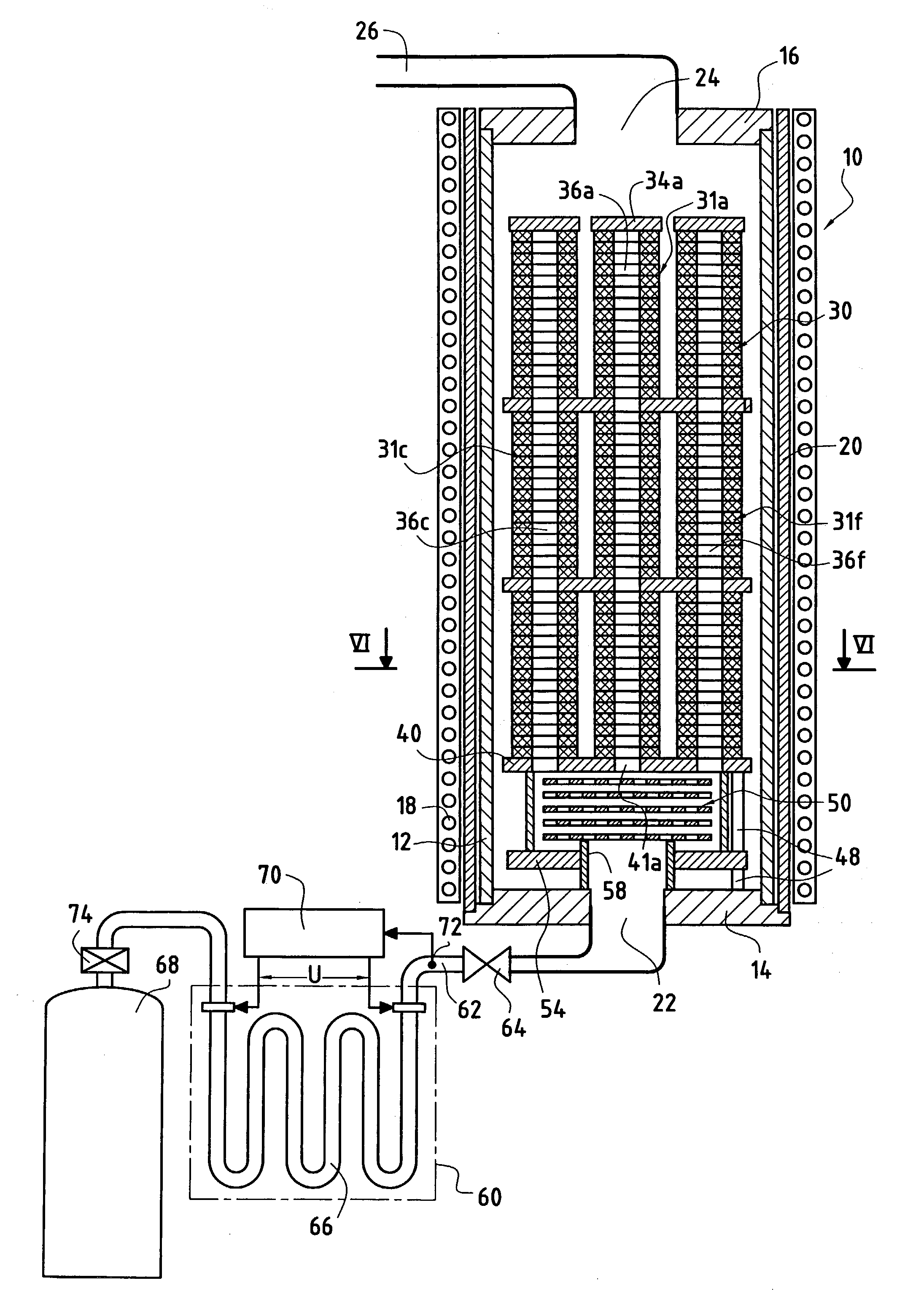

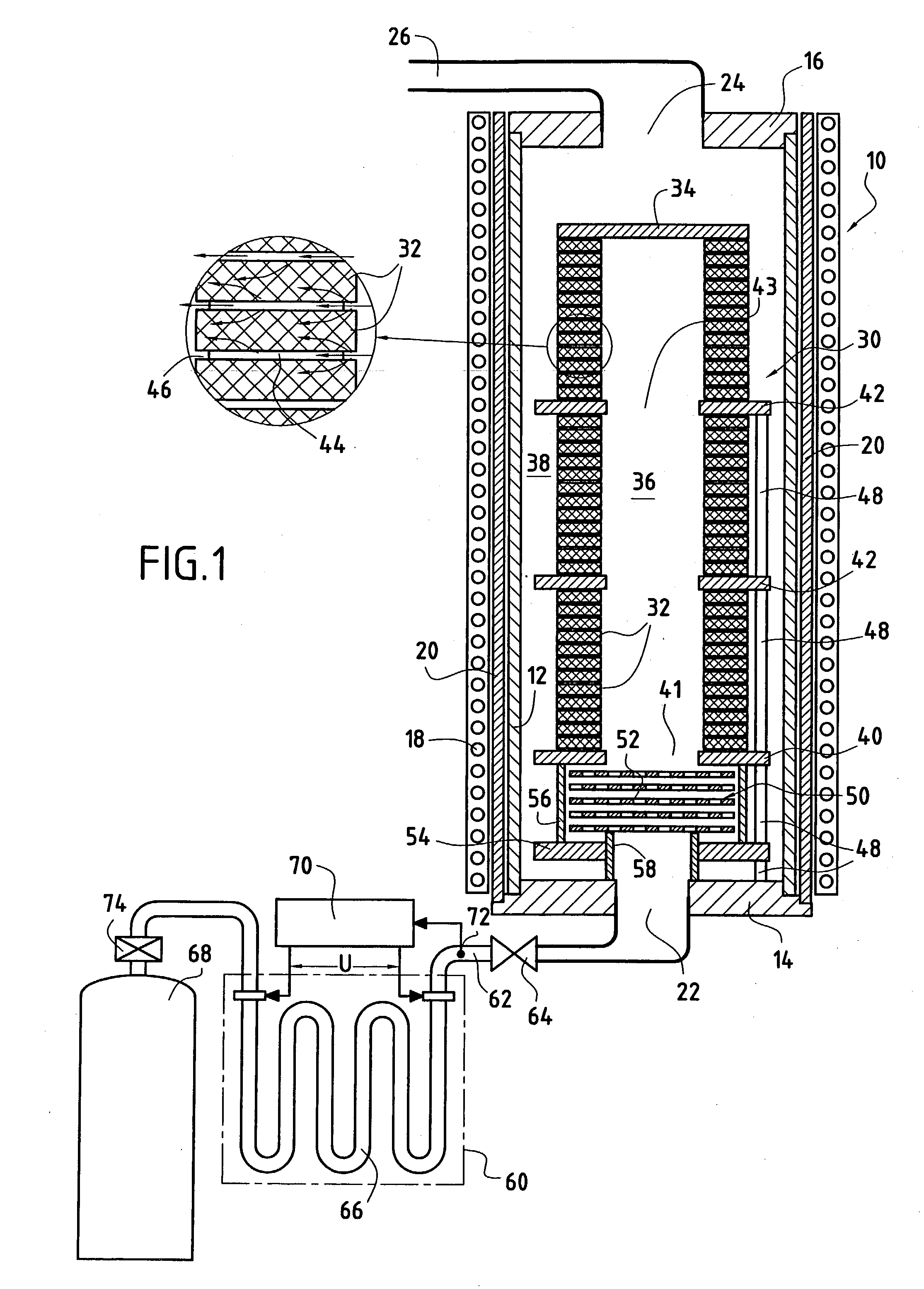

[0036] FIG. 1 is a diagram showing an oven 10 defined by a cylindrical side wall 12, a bottom wall 14, and a top wall 16. The wall 12 constitutes a secondary transformer circuit or susceptor, e.g. being made out of graphite, and it is coupled with a primary transformer circuit or induction coil 18 situated outside the oven, with insulation 20 interposed between them. The oven is heated by the susceptor 12 when electricity is fed to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com