Method and apparatus for increasing floating platform buoyancy

a floating platform and buoyancy technology, applied in the field of floating platform systems, can solve the problems of large capital expenditure, high cost of oil and gas recovery, and uneconomical production,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

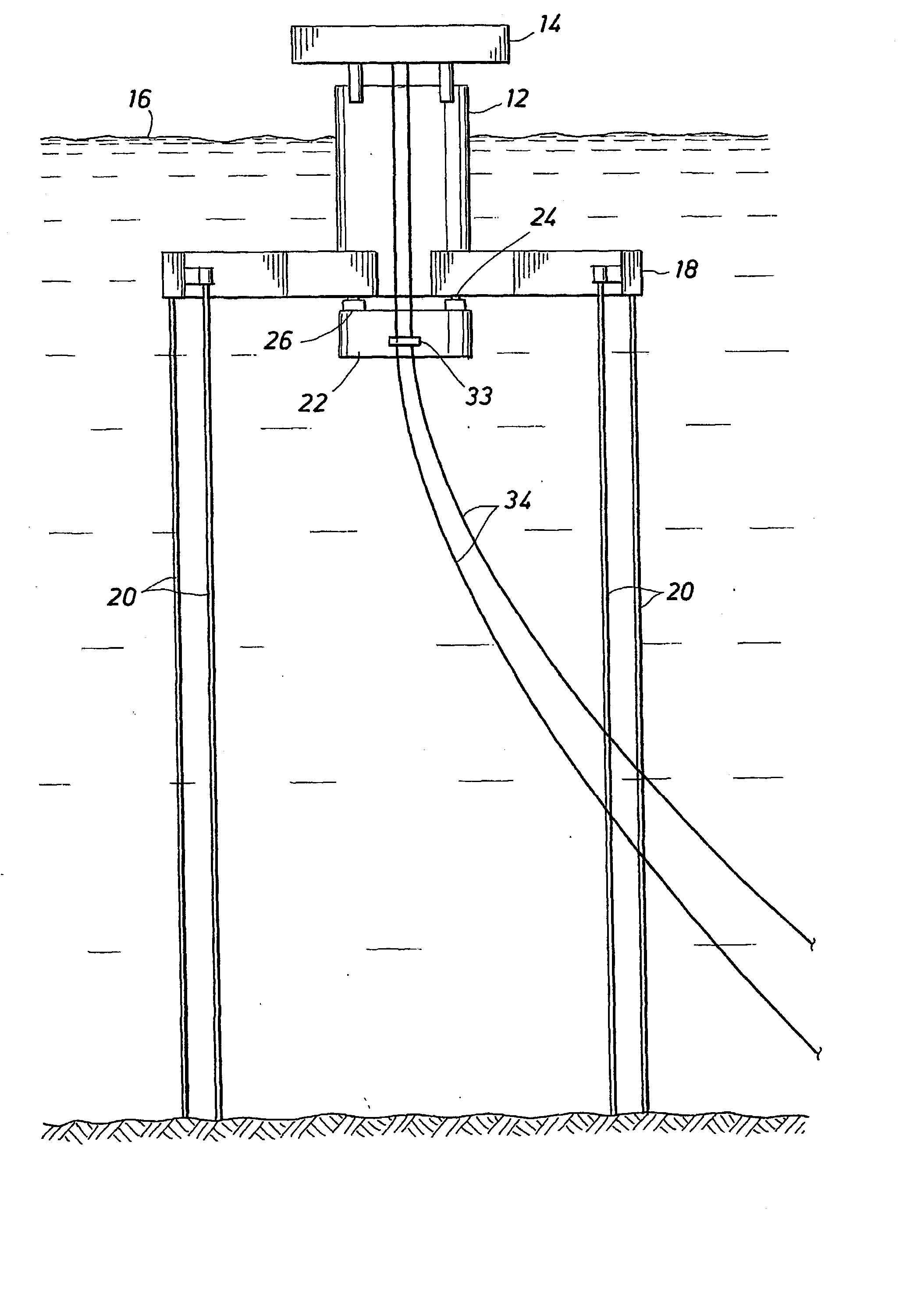

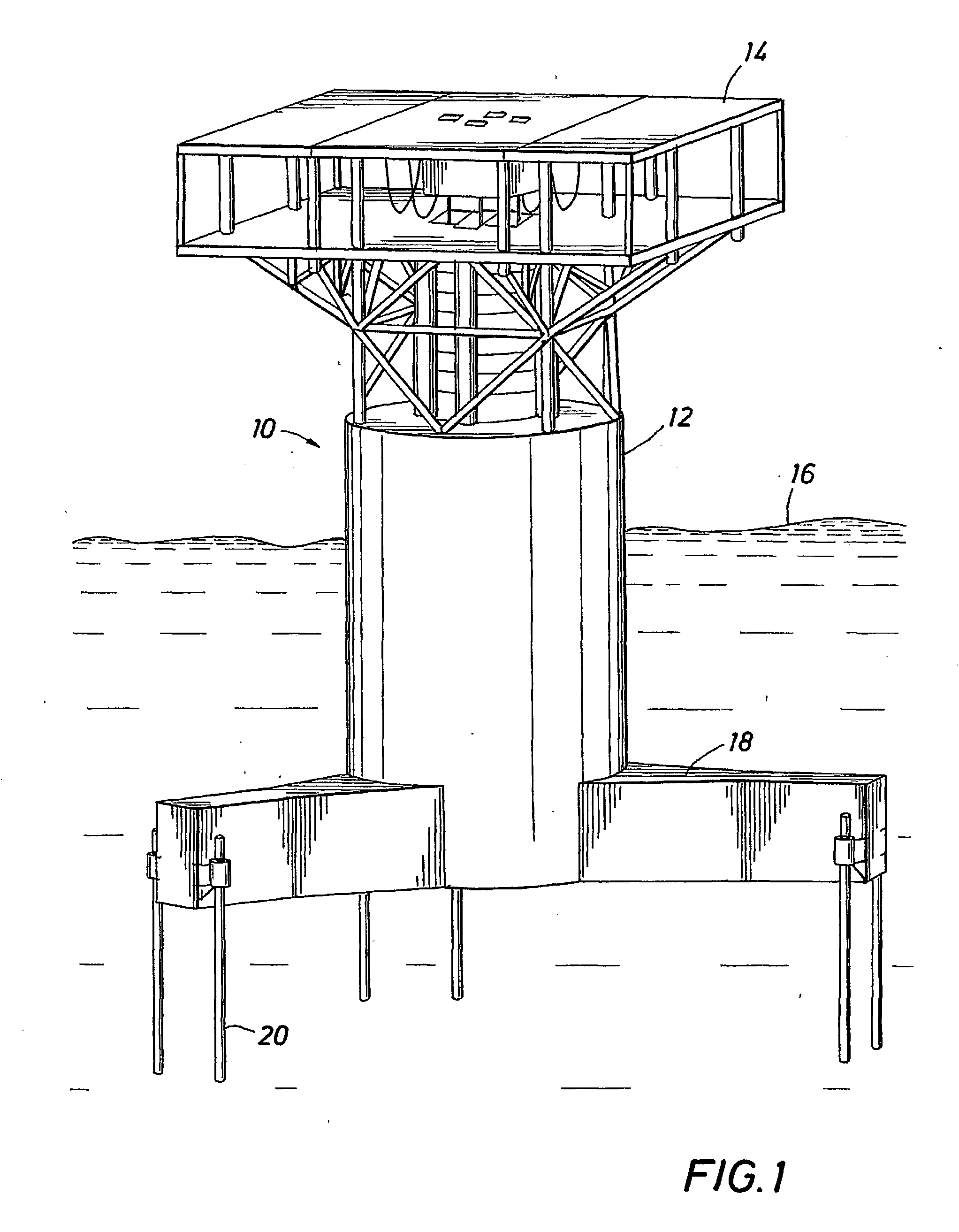

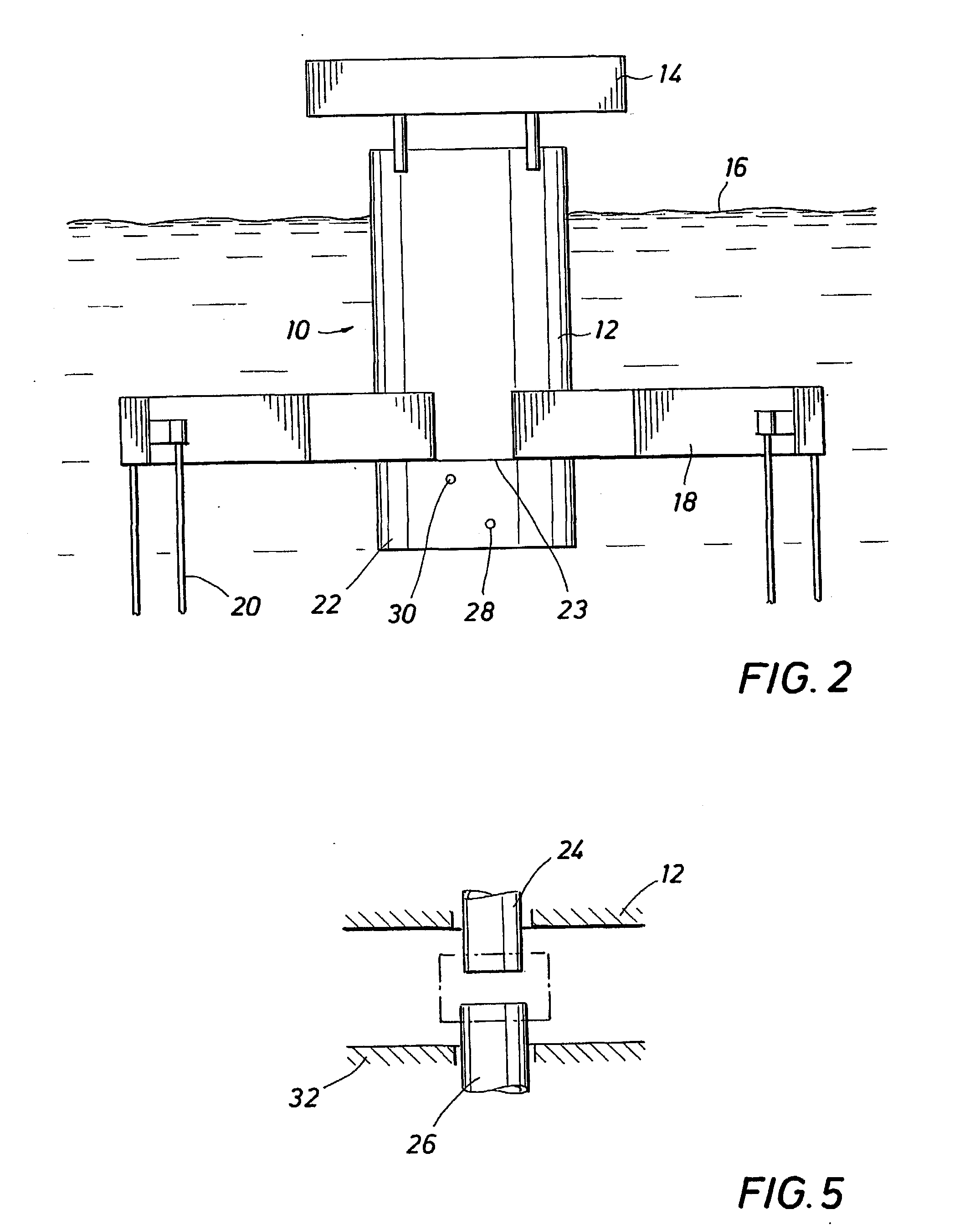

[0016] Referring first to FIG. 1, the floating platform of the invention is generally identified by the reference numeral 10. The platform 10 includes a central column or hull 12 which provides positive buoyancy and vertical support for the platform 10. One or more decks 14 are supported on the hull 12 above the water surface 16. Drilling and / or production equipment necessary for the recovery and processing of oil, gas and water recovered from the oil and gas field are secured on the deck 14.

[0017] The hull 12 extends upward from the base or keel of the hull 12. The base node of the hull 12 includes pontoons 18 extending radially outward from the hull 12. The platform 10 is anchored to the seabed by tendons 20 secured at one end thereof to the pontoons 18 and at the opposite ends thereof to foundation piles (not shown in the drawings) embedded in the seabed. The hull 12 provides sufficient buoyancy to support the payload of the platform 10, which payload includes the deck 14, drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com