Use of hemicellulase composition in mechanical pulp production

a technology of mechanical pulp and composition, which is applied in the field of mechanical pulp refining, can solve the problems of pulp material strength impairment and high energy consumption of grinding and refining wood or wood chips, and achieve the effect of less energy production and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Freeness

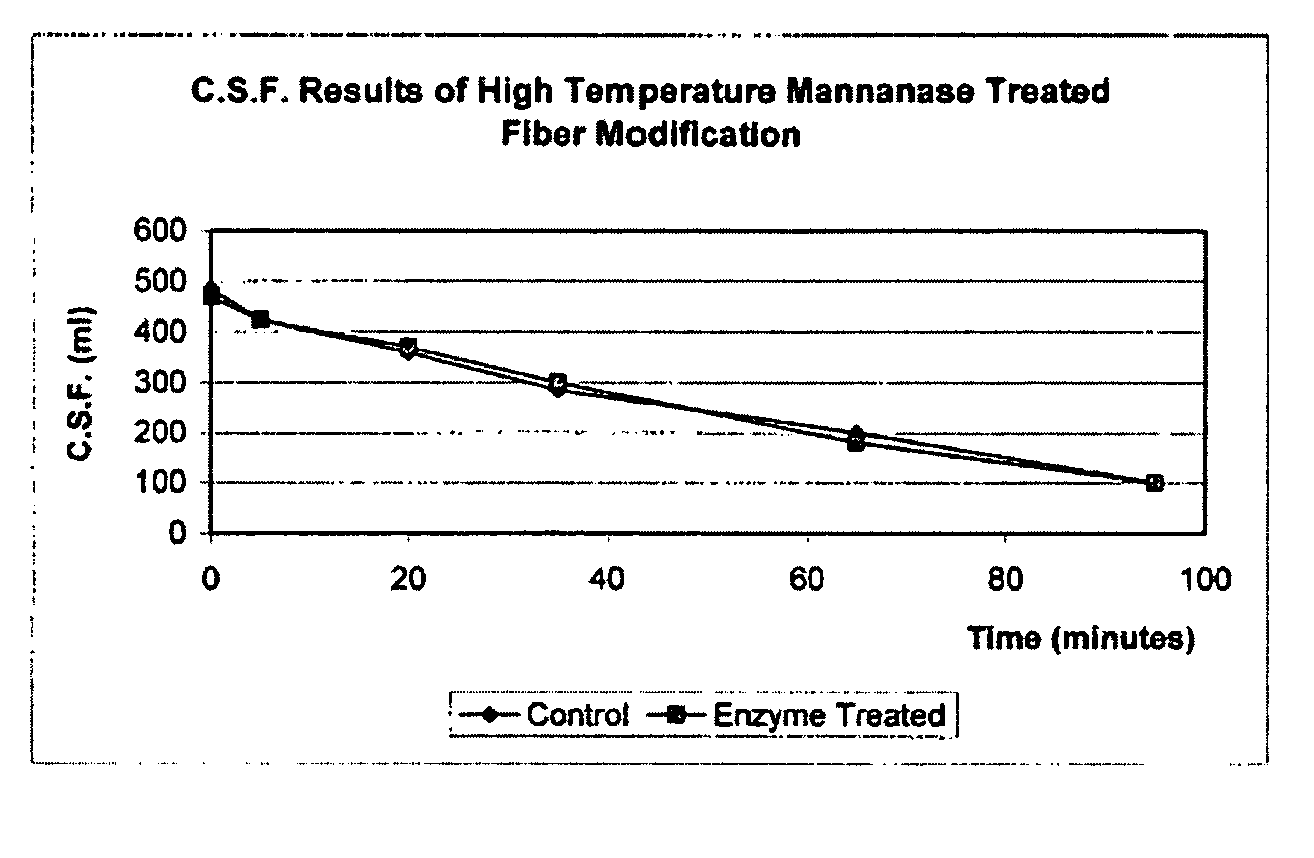

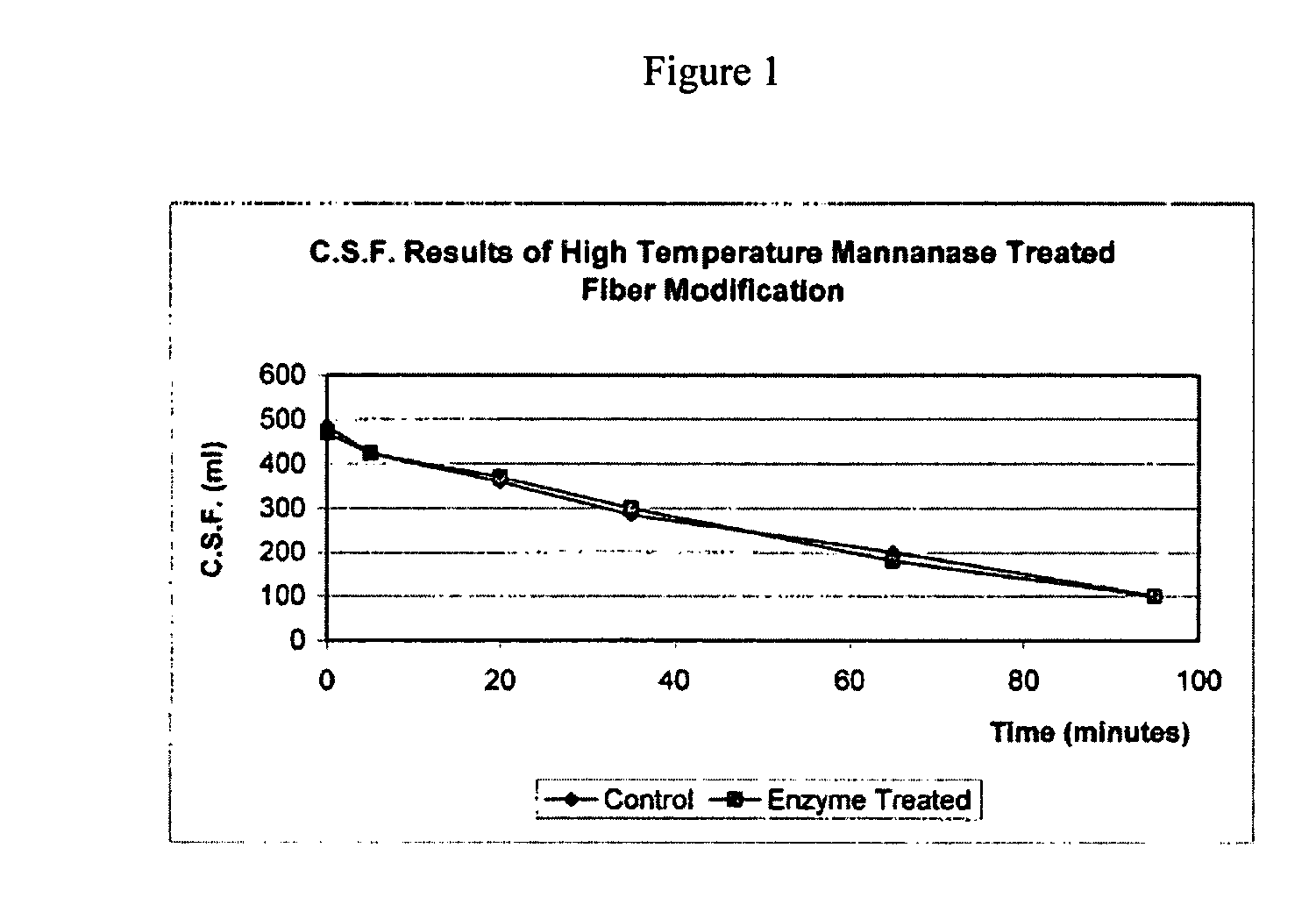

[0066] Mannanase was added in an amount of 0.171 pounds / ton dry pulp to TMP at a temperature of 85° C. The treated consistency was 3%. The treated pulp was placed in a Valley beater at a temperature of 20° C., a pH of 5.13, and the resulting pulp had a consistency of 1.57%. The treated TMP was measured for freeness at various time intervals during beating. A control sample was also measured. As the results in the table and FIG. 1 demonstrate, the freeness significantly affected by the treatment with mannanase.

Canada Standard Freeness (C.S.F.) Results ofMannanase Treated Fiber ModificationTimeControlMannanase Treated(minutes)Freeness ValueFreeness Value 0485470 542542520360370352853006520018095100100

example 2

Mannanase Activity Assay at Elevated Temperatures

[0067] Mannanase activity was determined using a 0.5% solution of locust bean gum galactomannan (available from Sigma-Aldrich, St. Louis, Mo., as Sigma G-0753) as the substrate. Diluted mannanase and the substrate were incubated at a targeted temperature and pH 5.0 for 5 min. Released reducing sugars were assayed by adding 3,5-dinitrosalicylic acid (DNS) solution. The mixture was boiled in a water bath for 5 min. After cooling, the absorbency was measured at 540 nm. The optimal temperature for this enzyme is about 80° C., as shown in the table below.

Temperature, ° C.Relative Activity, %4030503760567082801009061

example 3

Enzymatic Hydrolysis of Southern Pine TMP Reject Pulp

[0068] Southern pine TMP reject pulp with a consistency of 2.5% was treated with mannanase in an amount of 1 mg / g of pulp at 80° C. and pH 5.0 for 30 minutes. The control experiment was run at exactly the same conditions except mannanase was not added. The amount of reducing sugar released was determined by DNS method. The control did not release any detectable amount of reducing sugar, while the mannose-treated pulp released about 1 mg / g of pulp. This demonstrates that mannanase can hydrolyze the mannan component in TMP pulp in a relatively short time and at a high temperature similar to the conditions of a TMP mill process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com