High performance silicon condenser microphone with perforated single crystal silicon backplate

a silicon condenser microphone and silicon backplate technology, applied in the direction of deaf-aid sets, electrical transducers, electrical instruments, etc., can solve the problems of large air gap, large silicon micro-machining process problems, and silicon microphones reported so far have not achieved sensitivity of more than 20 mv/pa, and achieve low noise and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

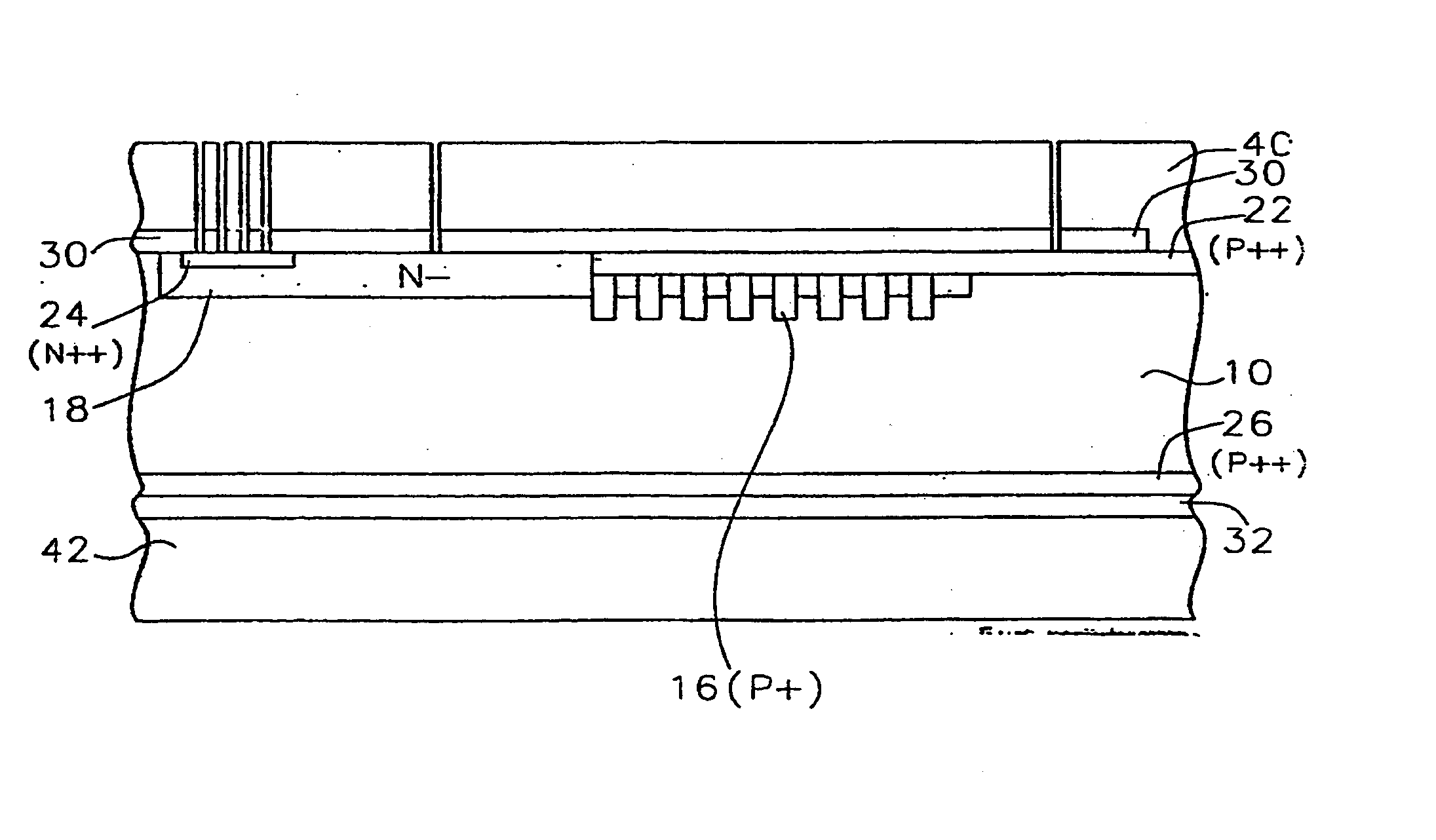

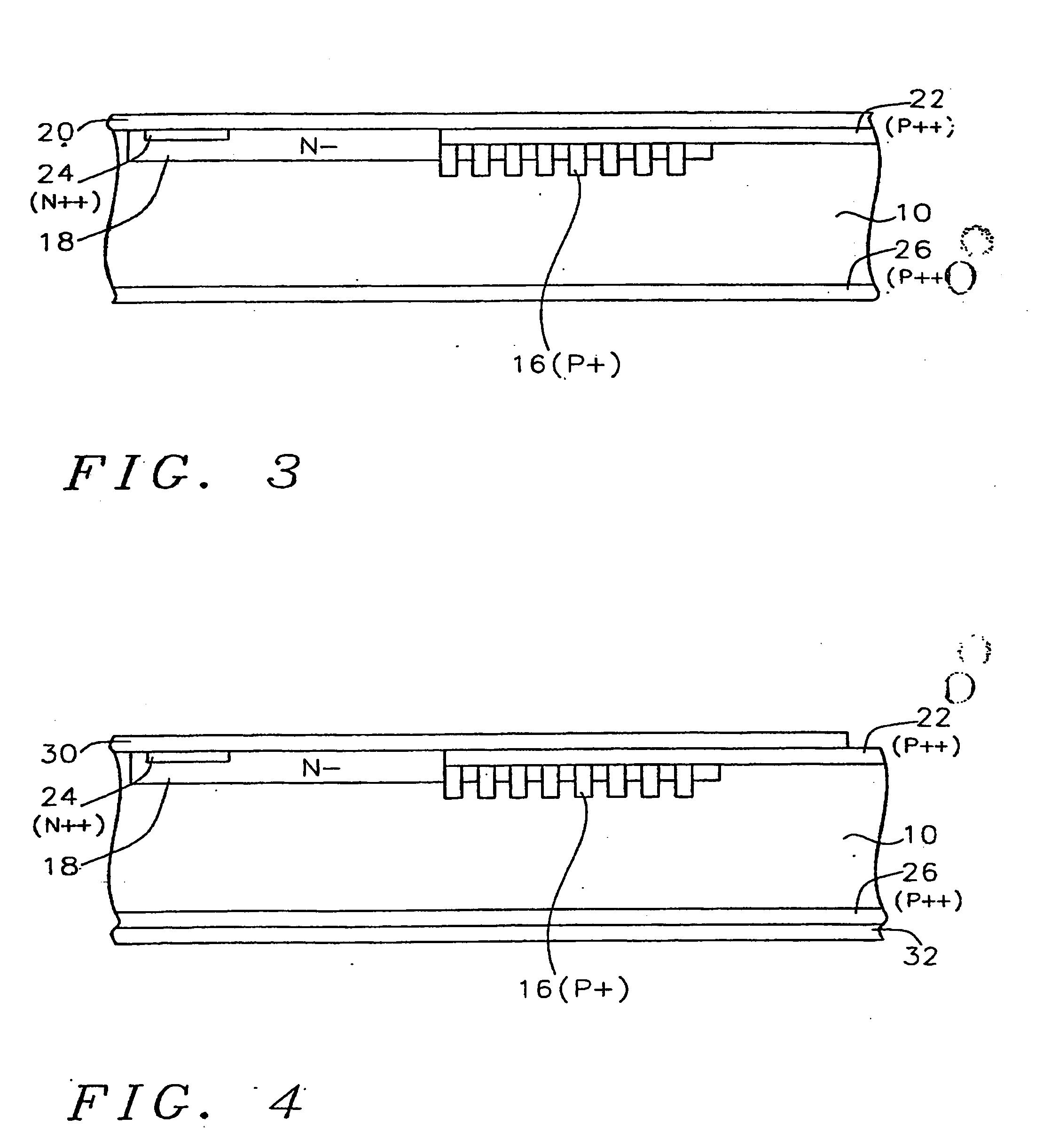

[0031] The present invention discloses a novel design and process for making a silicon condenser microphone. Referring now more particularly to FIG. 1, there is shown a semiconductor substrate 10, preferably composed of P-doped monocrystalline silicon. A thermal oxide layer 12 is grown on the surface of the substrate to a thickness of between about 270 and 330 Angstroms.

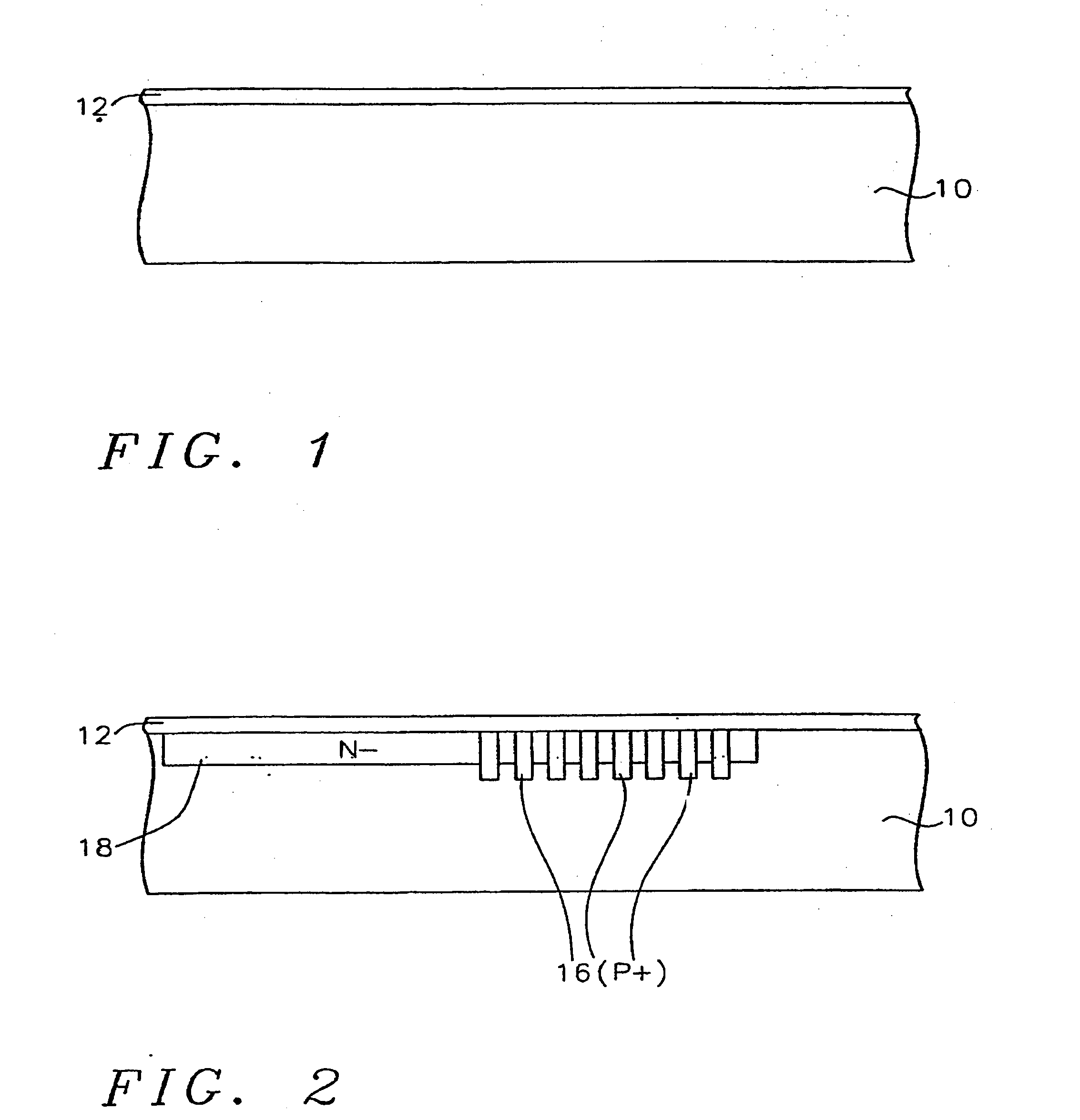

[0032] Referring now to FIG. 2, P+ implants 16 are made through a mask, not shown. These implanted regions 16 will form acoustic holes on the backplate in the later selective silicon etching process. The P+ implant condition must ensure the acoustic hole size at a desired backplate thickness. Now, an N− implanted region 18 is formed using a second mask, not shown. The N− implant condition must ensure a low stress backplate so that the backplate will not deform after the release process at the end of the fabrication process. The implanted ions are driven in to a depth of about 10 microns, which is the depth of the N−...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com