Chewing gum containing physiological cooling agents

a cooling agent and chewing gum technology, applied in chewing gum, cocoa, confectionery, etc., can solve the problems of difficult initial burst of flavor without, strong minty odor, harsh notes of chewing gum, etc., and achieve high flavor impact, without unwanted harshness or flavor characteristics, and high flavor impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

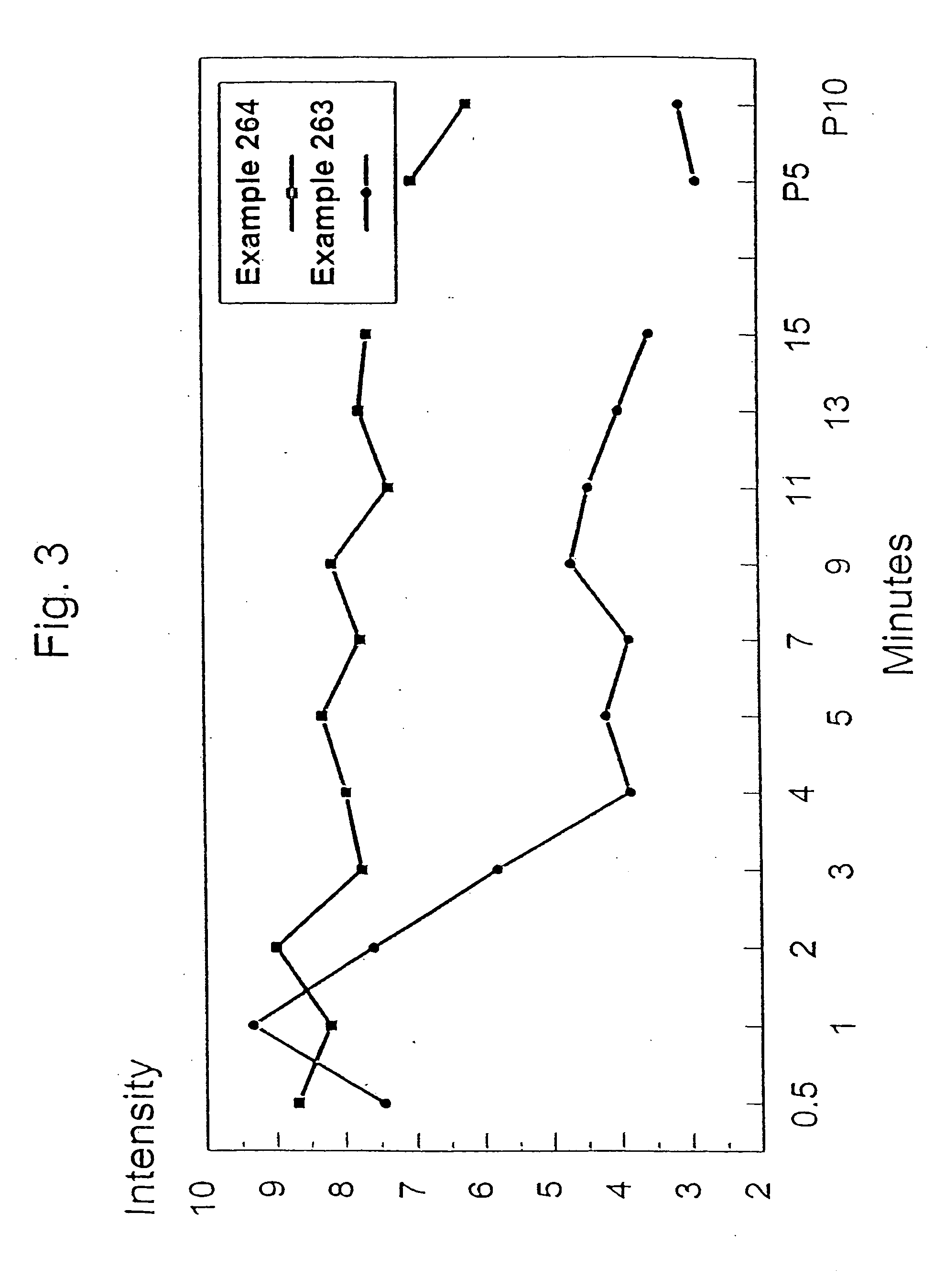

[0196] The following four ingredients can be mixed with flavors and used in chewing gum formulations. The percentage listed are percentages of the total of these four ingredients. However, the ingredients were not mixed together first, but were added individually to the flavor used in the gum. The four ingredients in combination are referred to herein as cooling blends A, B and C.

ABCMenthol52.560.262.5Menthone25.830.631.2Menthyl succinate14.56.14.2Menthyl lactate7.23.12.1

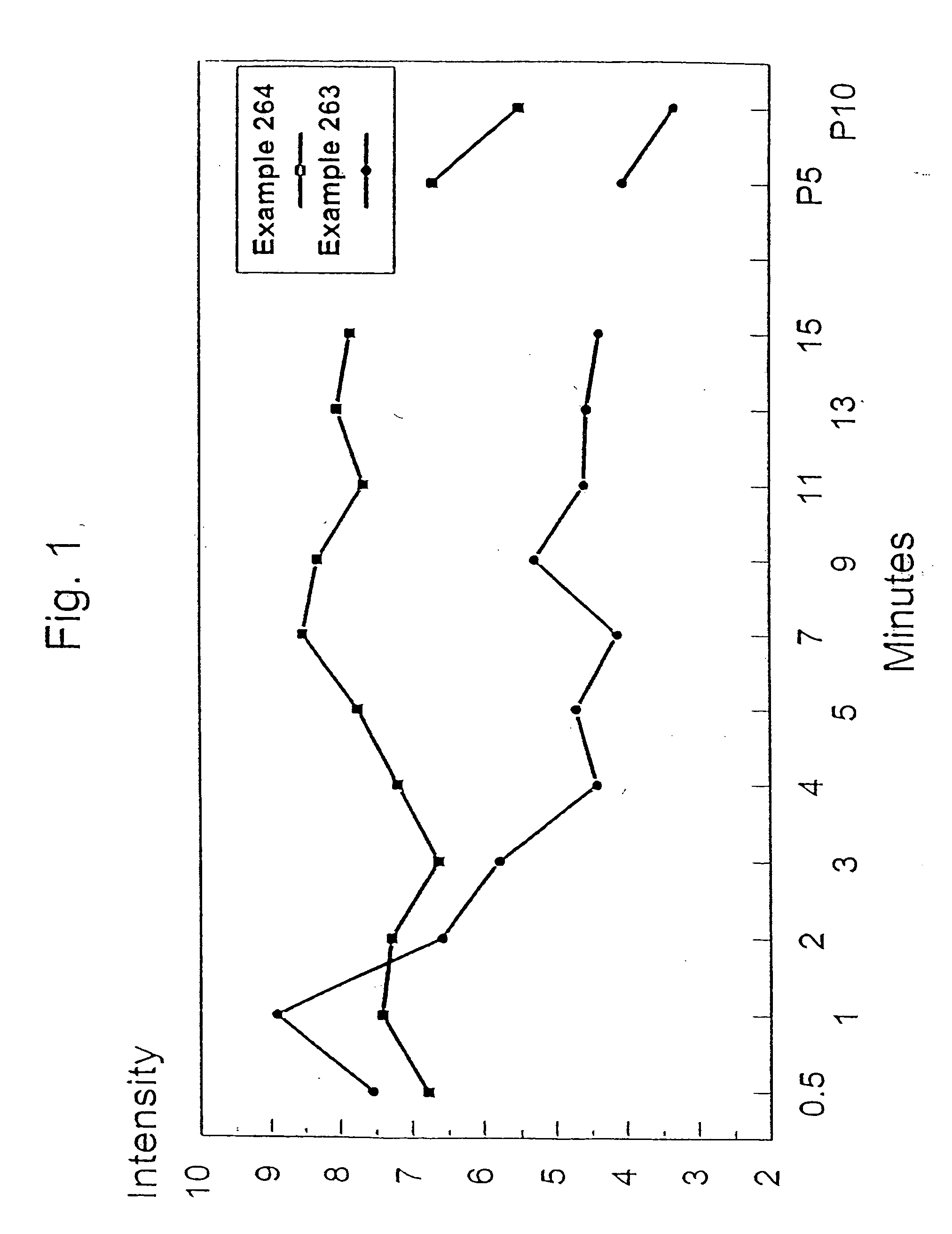

examples 1 and 2

[0197] Cooling blend A may be mixed with a cherry flavor and used to make two cherry flavored sugarless gum formulas. Both products would have a slightly minty flavor with cherry. When a peppermint flavor is used in place of the cooling blend in comparable formulas, the minty character is too strong. The cooling blend gives a high quality cool cherry mint flavored product as formulated below:

TABLE 1Example 1Example 2Sorbitol49.5151.44Base28.5025.00Glycerin12.0012.00Cherry Flavor3.08482.8848Cooling Blend A0.11520.1152Spray Dried Cherry Flavor0.30—Xylitol1.504.50Fumeric, Citric, and Adipic Acids2.102.10Encapsulated Sweeteners1.361.36Salt Solution0.75—Color0.280.30Lecithin0.500.30TOTAL100.00100.00

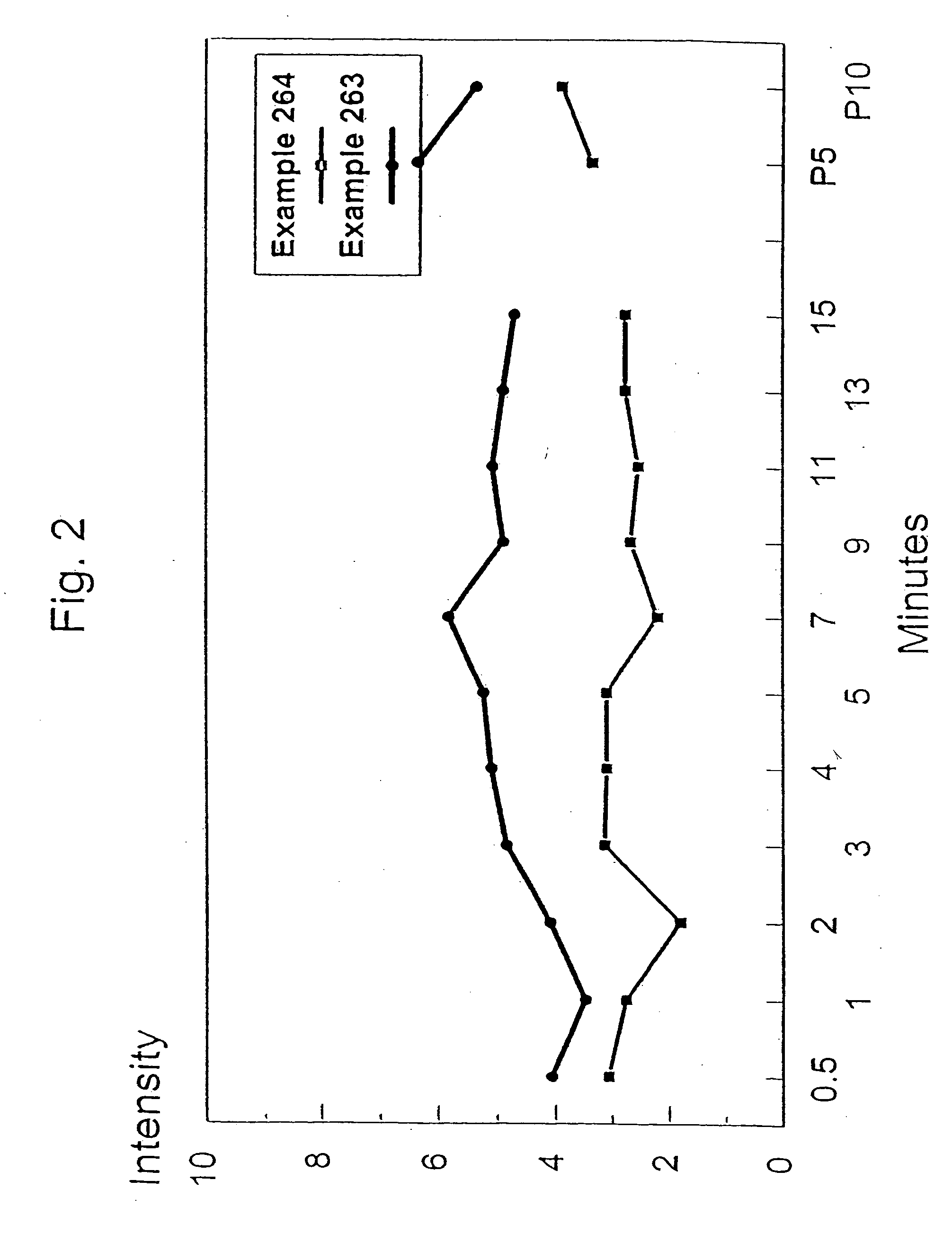

examples 3 , 4 and 5

Examples 3, 4 and 5

[0198] Cooling blend B may be used in a sugarless wintergreen flavored chewing gum to give improved cooling without mint flavor according to the following formulas:

TABLE 2Example 3Example 4Example 5Sorbitol49.6050.0148.76Base25.1025.1025.10Glycerin14.006.0014.00Maltitol5.007.0010.00Coevaporated Glycerin / Lycasin*3.509.50—Wintergreen Flavor1.12961.12961.1296Cooling Blend B0.47040.47040.4704Encapsulated Wintergreen Flavor0.16250.1625—Encapsulated Menthol0.08750.0875—Encapsulated Sweeteners0.540.540.54Salt Solution**0.28——Color0.13——TOTAL100.00100.00100.00

*Contains 25% glycerin, 67.5% Lycasin brand hydrogenated starch hydrolsate solids and 7.5% water.

**Contains 10% NaCl and 90% water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com