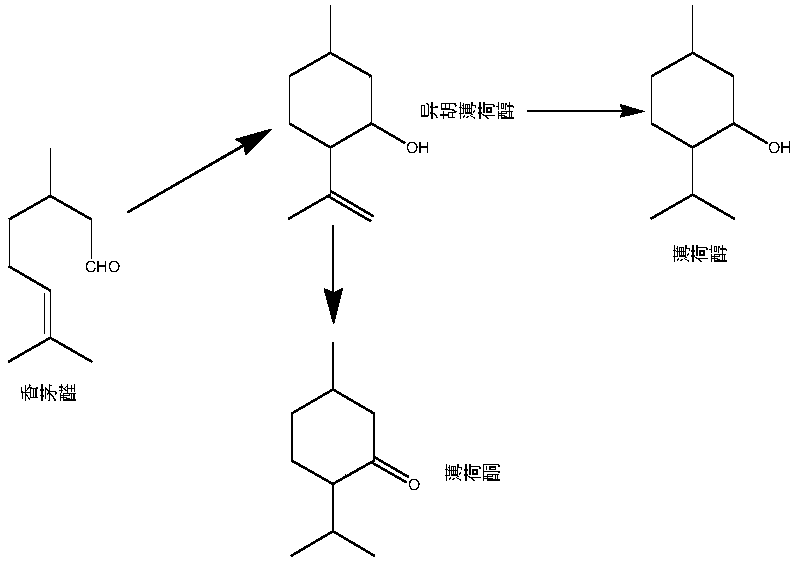

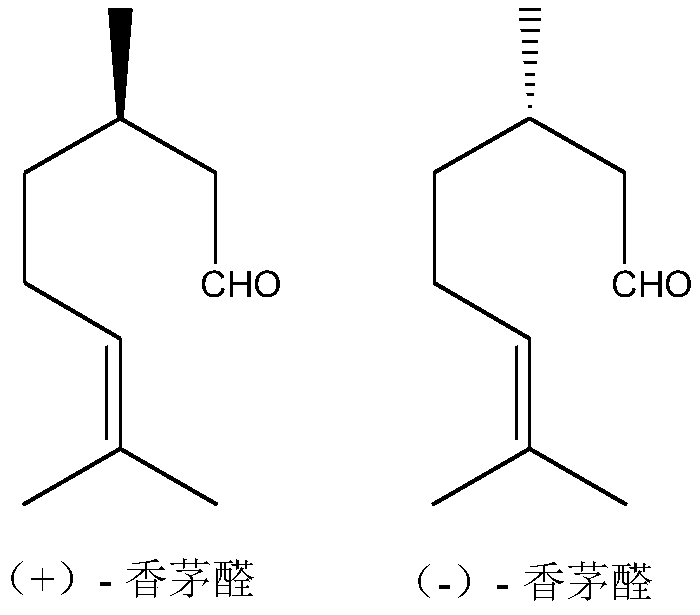

Method for preparing menthone from citronella aldehyde and catalyst system for the method

A technology of catalyst and menthone, which is applied in the field of preparation of menthone, can solve the problems of low selectivity of target products, increased cost of raw materials, increased difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

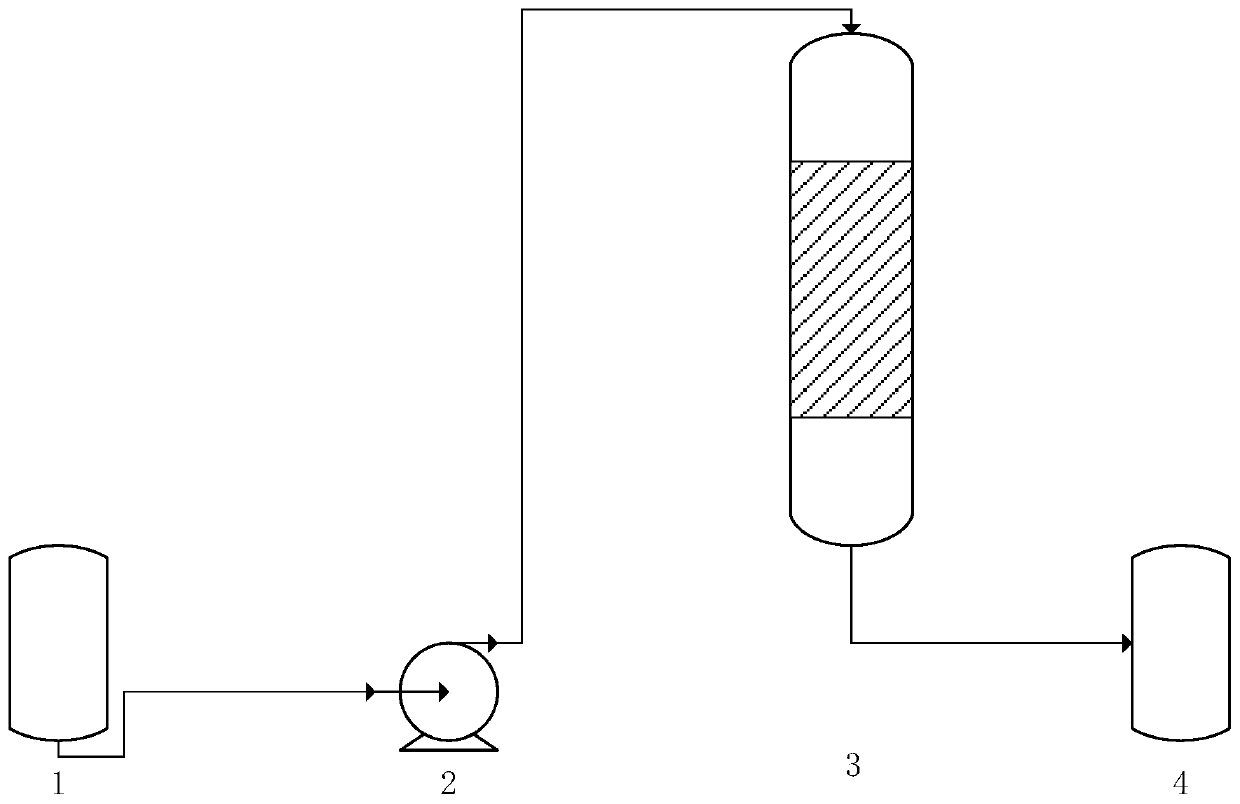

Method used

Image

Examples

Embodiment 1

[0058] Catalyst 0.5%Zn-1%Ru / Al 2 o 3 Preparation and reduction process:

[0059] Step a) with 50g Al 2 o 3 The carrier is fully dispersed in 250g of water, and maintains a highly dispersed state; in step b), the active components ruthenium and zinc are added simultaneously in the solution form of their metal salts ruthenium chloride and zinc chloride (5wt% aqueous solution, the same below), Wherein the addition of ruthenium chloride and zinc chloride is respectively 1.35g and 0.52g; step c) in order to precipitate the catalytically active component on the carrier, slowly add 0.5mol / L NaOH saturated solution, when the pH stability of the mixed solution At 9 o'clock, stop dripping lye; step d) after the active component is fully precipitated, the catalyst is separated from the water phase; e) the catalyst filter cake obtained is then dried under reduced pressure or inert gas, and then the dried The catalyst is calcined at a calcination temperature of 400°C for 5 hours to obt...

Embodiment 2

[0063] Catalyst 0.6%Zn-2%Ru / Al 2 o 3 Preparation and reduction process:

[0064] Step a) with 50g Al 2 o 3 The carrier is fully dispersed in 250g of water and remains in a highly dispersed state; in step b), the active components ruthenium and zinc are added simultaneously in the form of a solution of their metal salts ruthenium chloride and zinc chloride, wherein ruthenium chloride and zinc chloride The addition amount of each is 2.7g and 0.63g; step c) in order to precipitate the catalytically active component on the carrier, slowly add 0.5mol / LNaOH saturated solution, when the pH stability of the mixed solution is at 9, stop dripping the lye ; Step d) After the active components are fully precipitated, the catalyst is separated from the water phase; e) Then the obtained catalyst filter cake is dried under reduced pressure or inert gas, and then the dried catalyst is calcined at a calcining temperature of 450°C , calcined for 8 hours to obtain a catalyst precursor; f) We...

Embodiment 3

[0068] Catalyst 0.7%Zn-3%Ru / Al 2 o 3 Preparation and reduction process:

[0069] Step a) with 50g Al 2 o 3 The carrier is fully dispersed in 250g of water and remains in a highly dispersed state; in step b), the active components ruthenium and zinc are added simultaneously in the form of a solution of their metal salts ruthenium chloride and zinc chloride, wherein ruthenium chloride and zinc chloride The addition amount of each is 4.05g and 0.73g; step c) in order to precipitate the catalytically active component on the carrier, slowly add 0.5mol / LNaOH saturated solution, when the pH stability of the mixed solution is at 9, stop dripping the lye ; Step d) After the active components are fully precipitated, the catalyst is separated from the water phase; e) Then the obtained catalyst filter cake is dried under reduced pressure or inert gas, and then the dried catalyst is calcined at a temperature of 480°C , calcined for 18 hours to obtain a catalyst precursor; f) Weigh 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com