Method of making a metallic thin wire and a medical tool into which the metallic thin wire is incorporated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

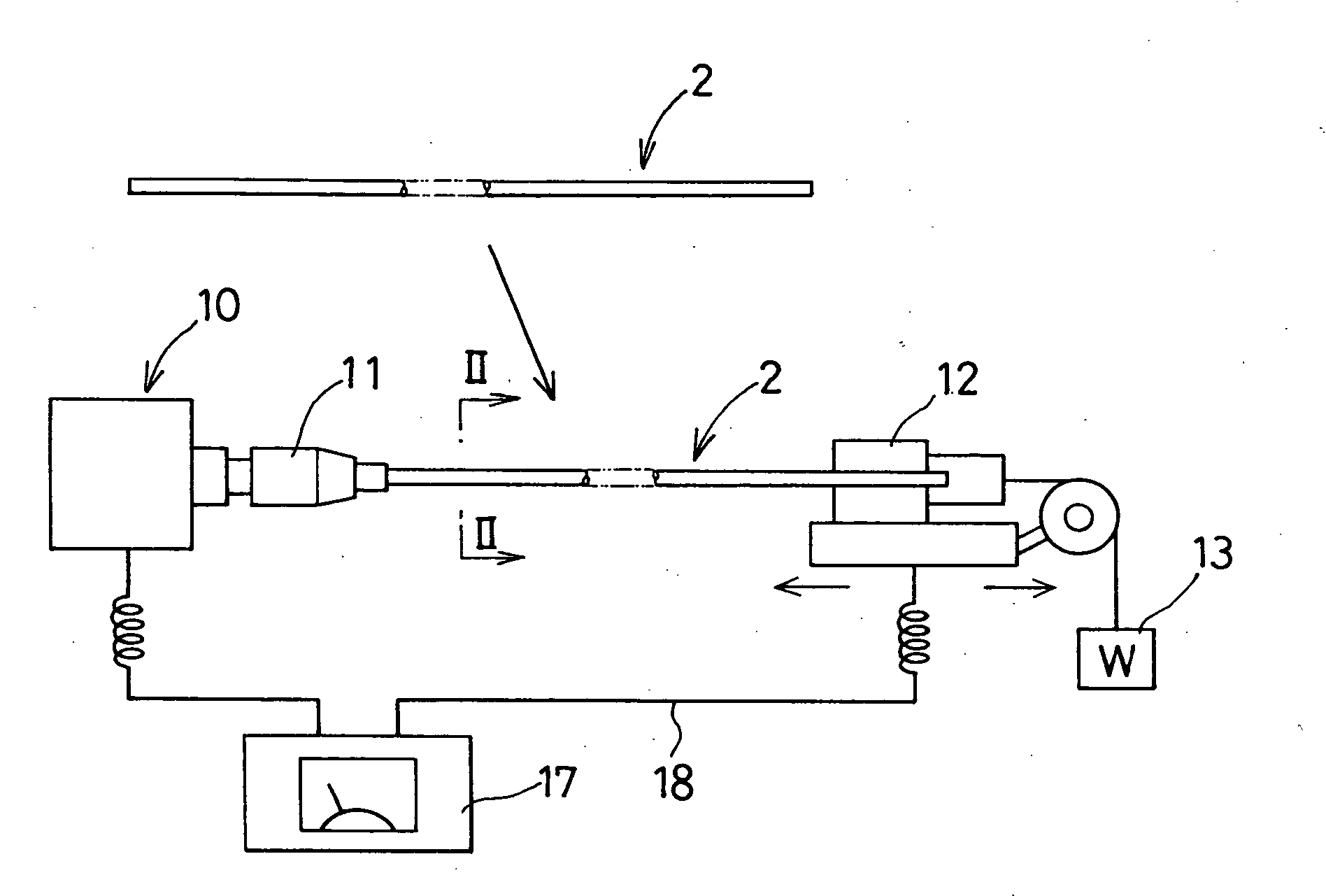

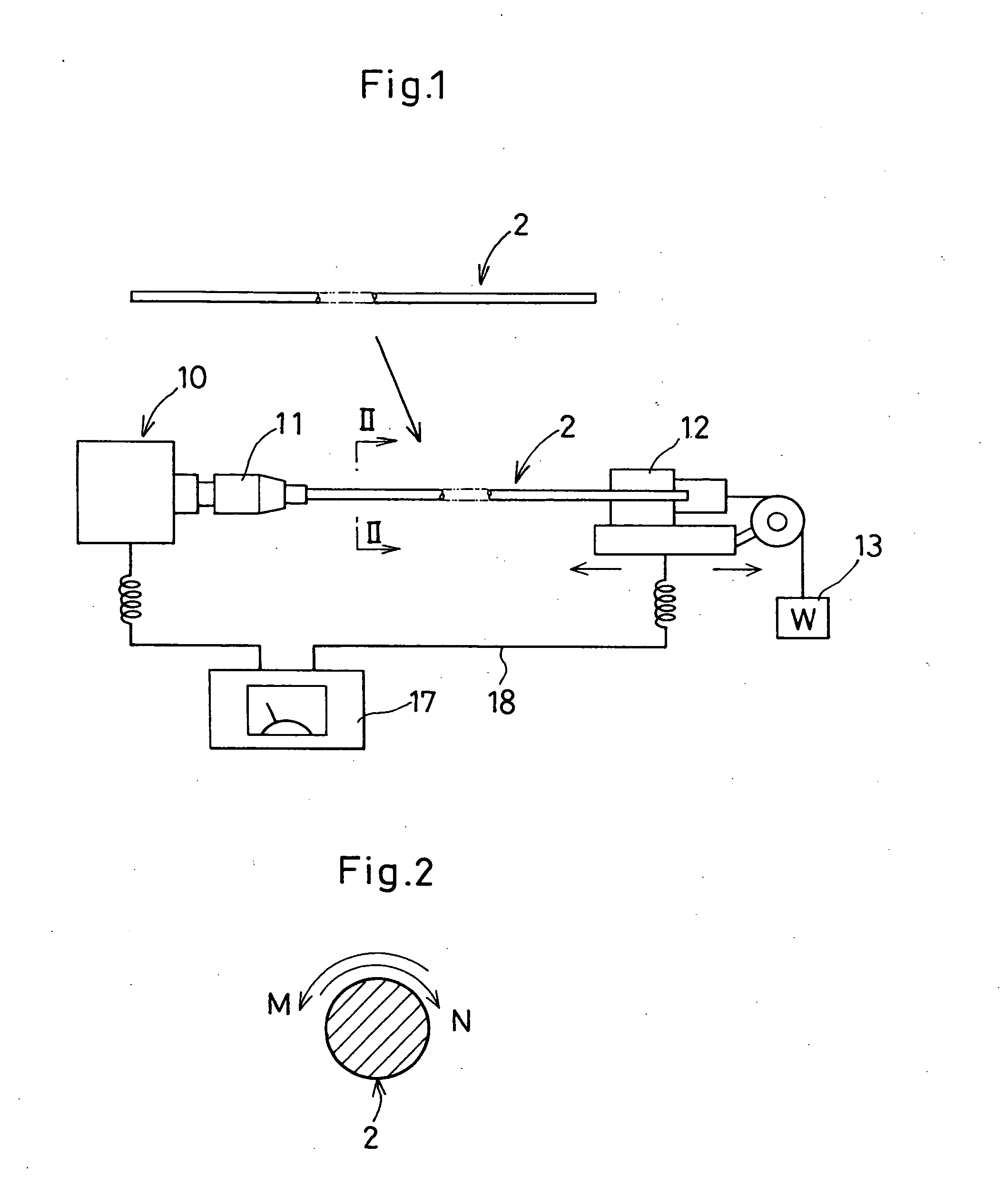

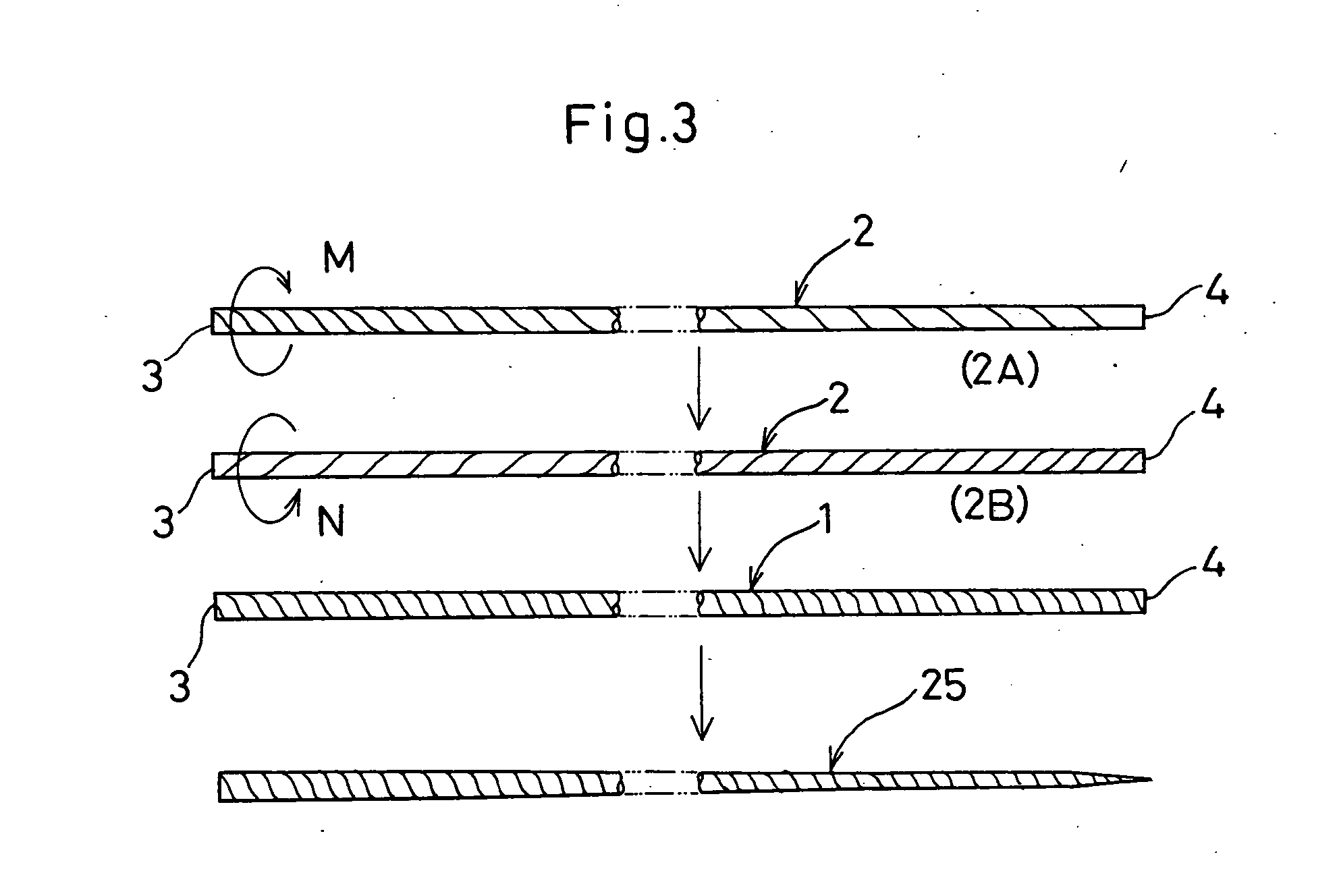

[0042] In the following description of the depicted embodiments, the same reference numerals are used for features of the same type. Referring to FIGS. 1 through 4, a method of making a metallic thin wire 1 according to the invention is described. The metallic thin wire 1 is used to a main wire component of a medicl guide wire 20, 20A and a balloon catheter 21 as shown in FIGS. 13 through 15. As a raw material of the metallic thin wire 1, one single metallic thin wire 2 (referred merely to as “thin wire 2” hereinafter) is drawn and severed to have a predetermined length and diameter as shown in FIG. 1. By way of illustration, the thin wire 2 is made of an austenitic stainless steel, and attached to a twisting device 10 to be twisted and processed with a heat treatment to remove a residual stress as described hereinafter.

[0043] The thin wire 2 has a predetermined length (e.g., 1,000-1,500 mm), one end of which is firmly clamped by a rotary chuck 11. The other end of the thin wire 2 i...

second embodiment

[0050]FIGS. 5 through 8 show the invention in which the thin wire 2 is divided into a plurality of zones X, Y and Z in the lengthwise direction. The zones X, Y and Z in turn have different twisted numbers of times after the thin wire 2 is primarily and secondarily twisted depending on the zones X, Y and Z. When the thin wire 2 is used to the medical guide wire 20, 20A and the balloon catheter 21 as shown in FIGS. 13 through 15, the zone X has the largest numbers of twisted times to position near a hand access section 27 with the smallest numbers of twisted times given to the zone Z. The zone Y, which positions between the zone X and the zone Z, has a middle numbers of twisted times between the largest and smallest numbers of twisted times. In this way, the thin wire 2 are wrought out to have the different numbers of twisted times discretely depending on the zones X, Y and Z.

[0051] In the second embodiment of the invention, an intermediary clamp device 14 is slidably placed between t...

fourth embodiment

[0055]FIG. 12 shows the invention in which a dual rotary chuck 11A is provided in the twisting device 10. An extension of the thin wire 2 is a bifold of the predetermined length. A middle section of the thin wire 2 is firmly clamped by the dual rotary chuck 11A. Both ends of the thin wire 2 is clamped by a slidable chuck 12A which hangs down the tensile weight W.

[0056] In this instance, the thin wire 2 symmetrically locates its right (front) half portion and left (rear) half portion in a dual fashion. Thereafter, the right and left half portions are primarily and secondarily twisted in the same manner as done in the first embodiment of the invention. With the use of the dual rotary chuck 11A, two metallic thin wires can be produced concurrently, thus reducing the manufacturing cost with a high productivity. The two metallic thin wires is produced under the same conditions, thus contributing to equalizing the quality of the product.

[0057]FIG. 13 shows a fifth embodiment of the inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap