Circuit device and manufacturing method of circuit device

a manufacturing method and circuit device technology, applied in the field of circuit devices, can solve the problems of too large total size to meet the requirements of smaller, thinner and lighter requirements, difficult to provide an electrical circuit device in size, thickness and weight reduction, etc., and achieve the effect of preventing slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0130] First Embodiment for Circuit Device

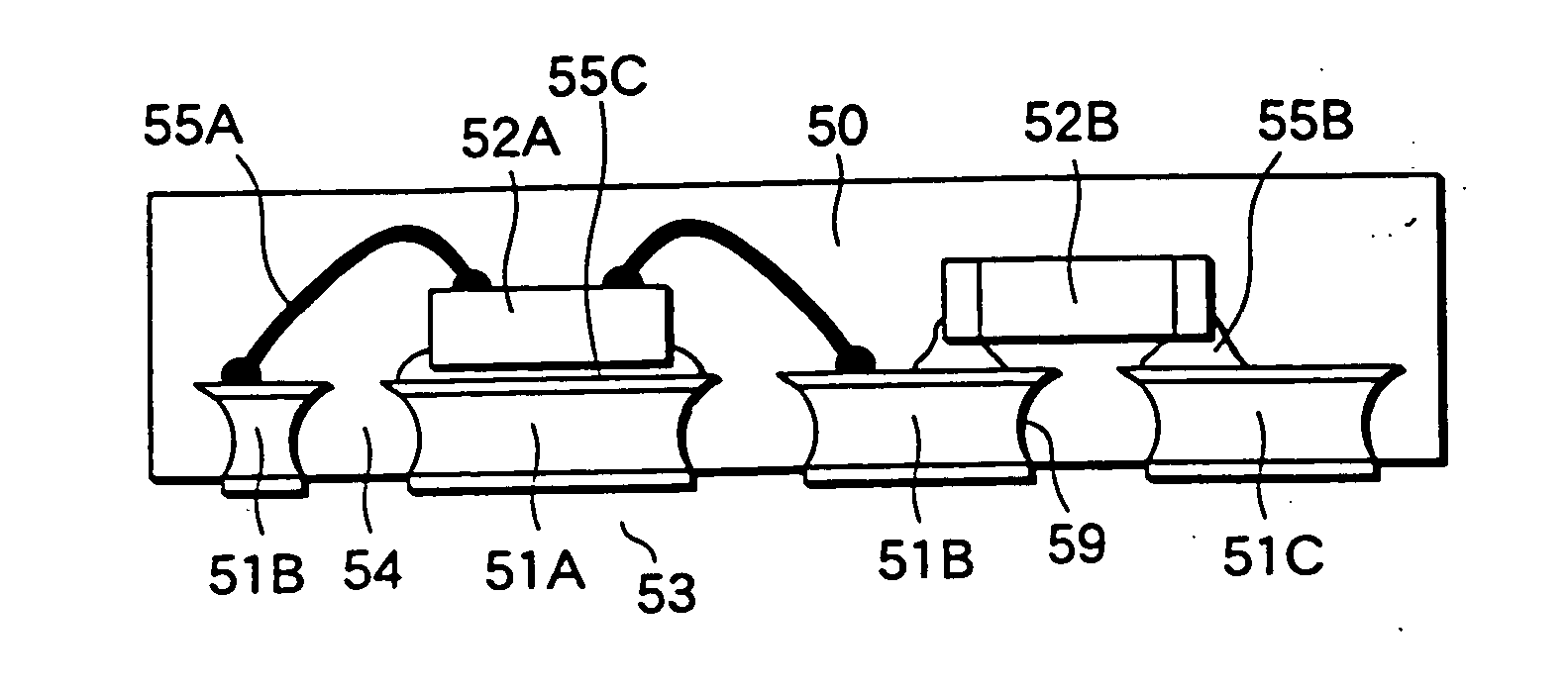

[0131] Referring to FIG. 1, a circuit device of the present invention will be first described below in connection with its structure.

[0132]FIG. 1 shows a circuit device 53 in which a conductive path 51 is buried into an insulating resin 50, and a circuit device 52 is fixed on said conductive path 51 supported by the insulating resin 50. The lateral face of the conductive path 51 has a curved structure 59.

[0133] This circuit device is mainly composed of the circuit elements 52A, 52B, a plurality of conductive paths 51A, 51B and 51C, and the insulating resin 50 into which the conductive paths 51A, 51B and 51C are buried. Between the conductive paths 51, a trench 54 is filled with the insulating resin 50. And the insulating resin 50 supports the conductive paths 51 of the curved structure 59.

[0134] The insulating resin may be a thermosetting resin, such as epoxy resin, or a thermoplastic resin, such as polyimide resin and polyphenylene sulfi...

second embodiment

[0150] Second Embodiment for Circuit Device

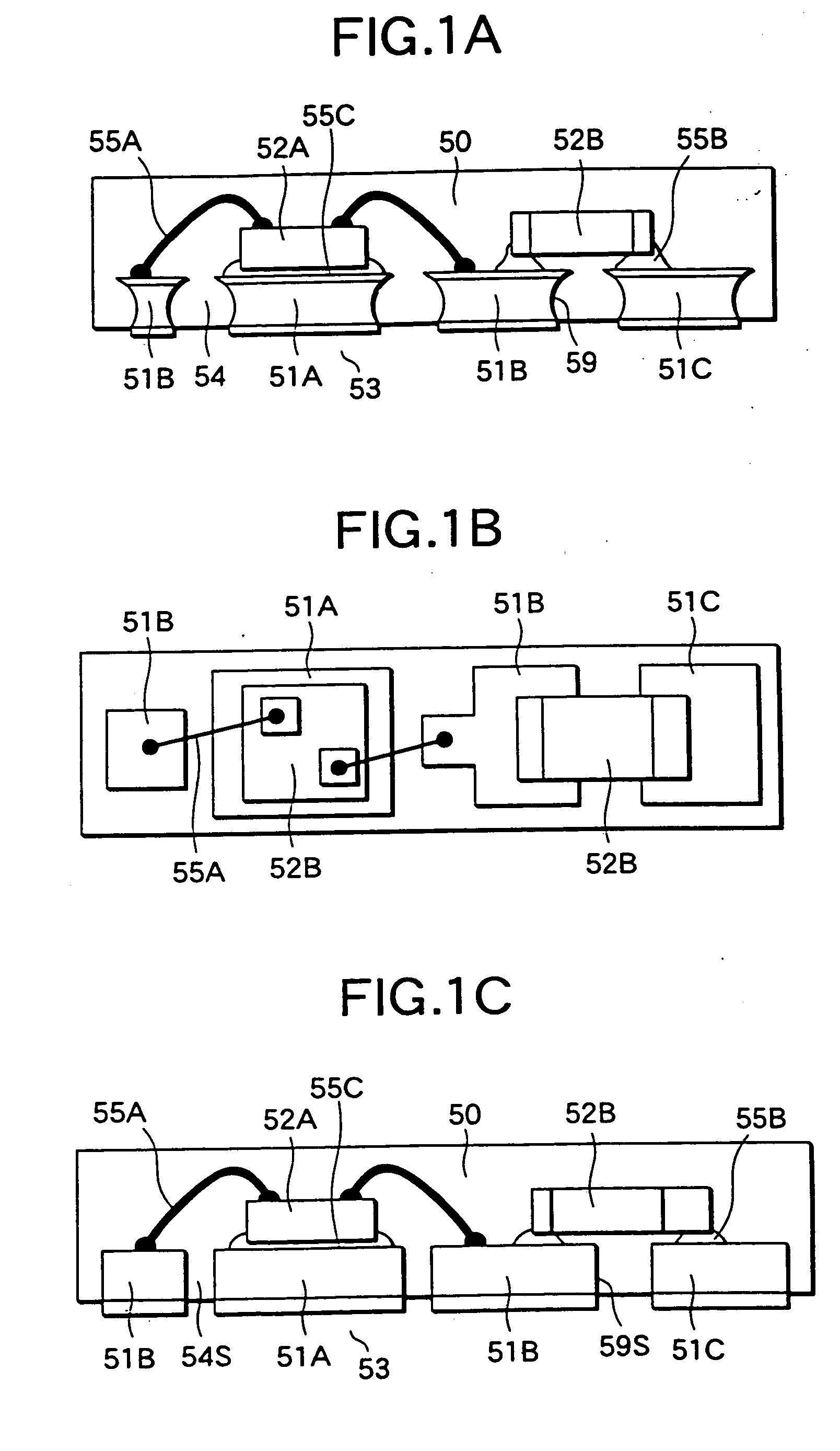

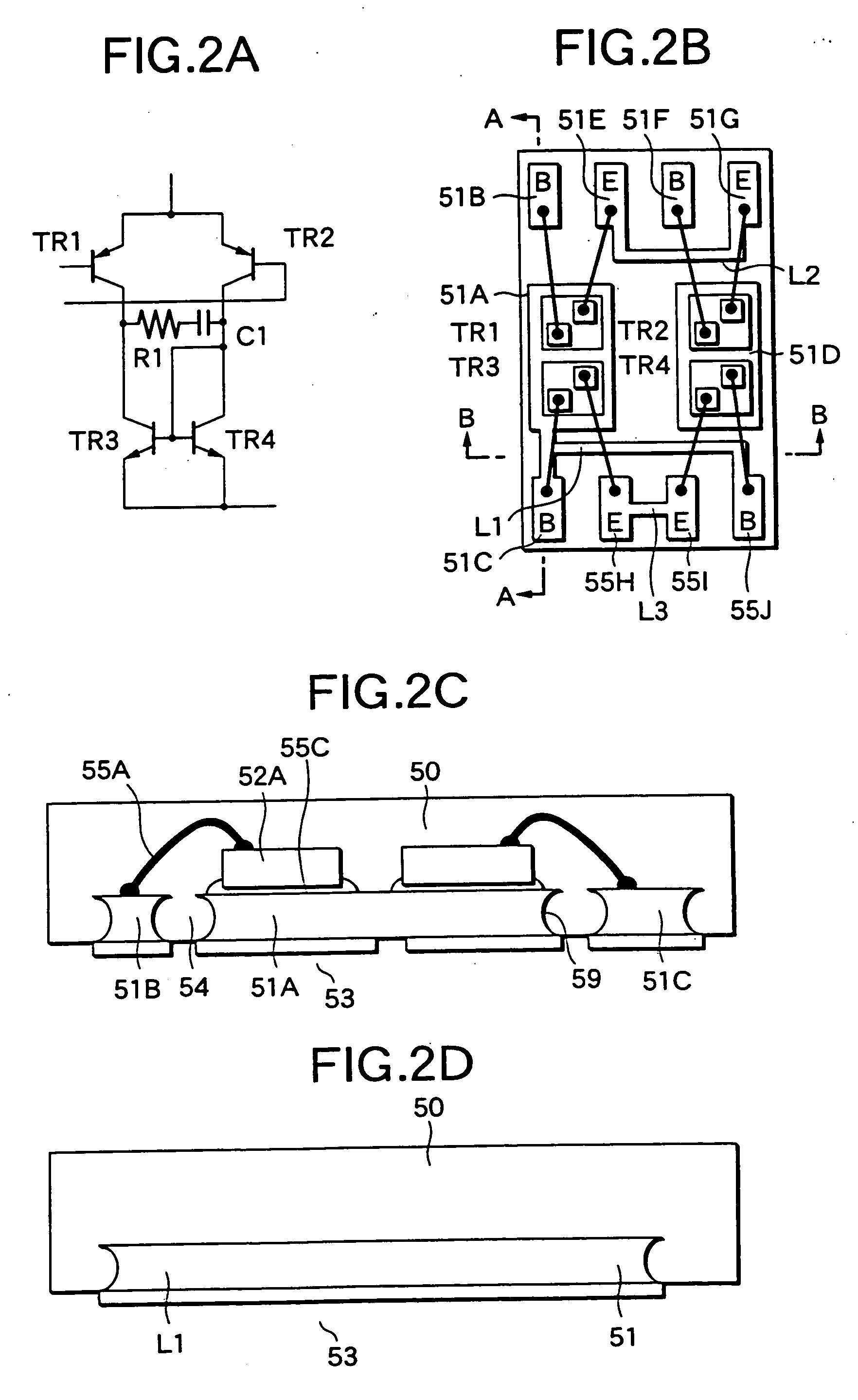

[0151] A circuit device 53 of FIG. 2 will be described below.

[0152] This circuit device has substantially the same structure as that of FIG. 1, except that the interconnects L1 and L2 are formed as the conductive paths 51. Accordingly, the interconnects L1 and L2 will be described below.

[0153] As described before, there are a wide variety of IC circuits from a small-scale circuit to a large-scale circuit. For the convenience of the drawings, the small-scale circuit is only shown in FIG. 2A. This circuit is most applicable to an audio amplifying circuit having a difference amplifying circuit and a current mirror circuit connected. The difference amplifying circuit is constituted of a TR1 and a TR2, and the current mirror circuit is constituted of a TR3 and a TR4, as shown in FIG. 2A.

[0154]FIG. 2B is a plan view of the circuit device to which the circuit of FIG. 2A is applied. FIG. 2C is a cross-sectional view taken along the line A-A in F...

third embodiment

[0158] Third Embodiment for Circuit Device

[0159] A circuit device 56 of FIG. 8 will be described below.

[0160] This circuit device has substantially the same structure of FIG. 1 or 2, except that a conductive coat 57 is formed on the surface of the conductive paths 51. Herein, the conductive coat 57 on the conductive paths will be mainly described below.

[0161] A first feature is to provide the conductive coat 57 to prevent the circuit device or the conductive path 51 from warping.

[0162] Typically, due to a difference in thermal expansion coefficient between the insulating resin and the conductive path material (hereinafter referred to as a first material) the circuit device itself may be warped, or the conductive path curved or peeled. Since the thermal conductivity of the conductive paths 51 is superior to that of the insulating resin, the conductive paths 51 will rise in temperature more rapidly, and expand. A second material having a smaller thermal expansion coefficient than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com