Nonaqueous electrolyte battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

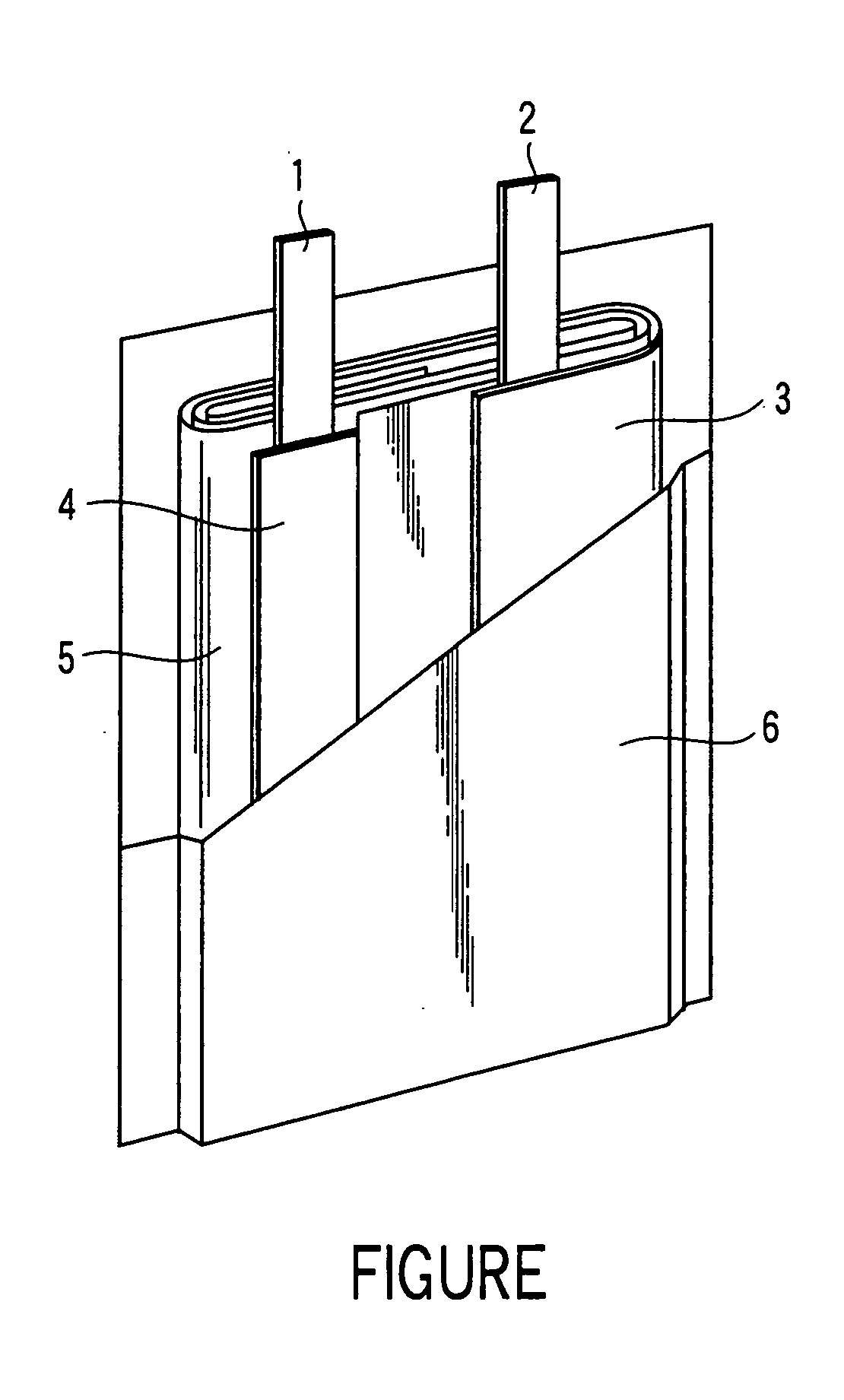

A battery having the structure shown in FIGURE 1 was fabricated. Examples 2 to 4 and Comparative examples 1 to 4 are same in structure as shown in FIGURE 1.

<Preparation of Positive Electrode>

By blending 90 wt. % of lithium cobalt oxide (LiCoO2) as an active material, 3 wt. % of acetylene black, 3 wt. % of graphite, and 4 wt. % of polyvinylidene fluoride (PVdF) in n-methyl pyrrolidone (NMP), a slurry was prepared. The slurry was applied on both sides of a current collector made of an aluminum foil of 15 μm in thickness, and dried and pressed, and a positive electrode with electrode density of 3.0 g / cm3 was prepared.

<Preparation of Negative Electrode>

By blending Li4Ti5O12 as a negative electrode active material, coke with average particle size of 1.12 μm and specific surface area of 82 m2 / g as an electronic conductor, and polyvinylidene fluoride (PVdF) by a ratio of 90:5:5 by weight, the mixture was dispersed in n-methyl pyrrolidone (NMP) solvent, and a slurry was prepa...

example 2

A nonaqueous electrolyte secondary battery same as in Example 1 was manufactured except that the electronic conductor was replaced by coke of which average particle size is 3.37 μm, specific surface area is 25.7 m2 / g, spacing (d002) of (002) plane is 0.3472 nm, and crystallite size (Lc) in the C-axis direction is 1.90 nm.

example 3

A nonaqueous electrolyte secondary battery same as in Example 1 was manufactured except that the electronic conductor was replaced by coke of which average particle size is 5.87 μm, specific surface area is 12.7 m2 / g, spacing (d002) of (002) plane is 0.3443 nm, and crystallite size (Lc) in the C-axis direction is 1.90 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com