Connector coupling/decoupling tool

a technology for coupling/decoupling tools and connectors, which is applied in the direction of manufacturing tools, instruments, transportation and packaging, etc., can solve the problems of increasing the density of connector ports, increasing the size of electronic equipment, and increasing the volume of connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is described by the following examples. It should be recognized that variations based on the inventive features disclosed herein are within the skill of the ordinary artisan, and that the scope of the invention should not be limited by the examples. To properly determine the scope of the invention, an interested party should consider the claims herein, and any equivalent thereof. In addition, all citations herein are incorporated by reference. In the context of this invention, substantially similar components are referenced by the same number in the different figures.

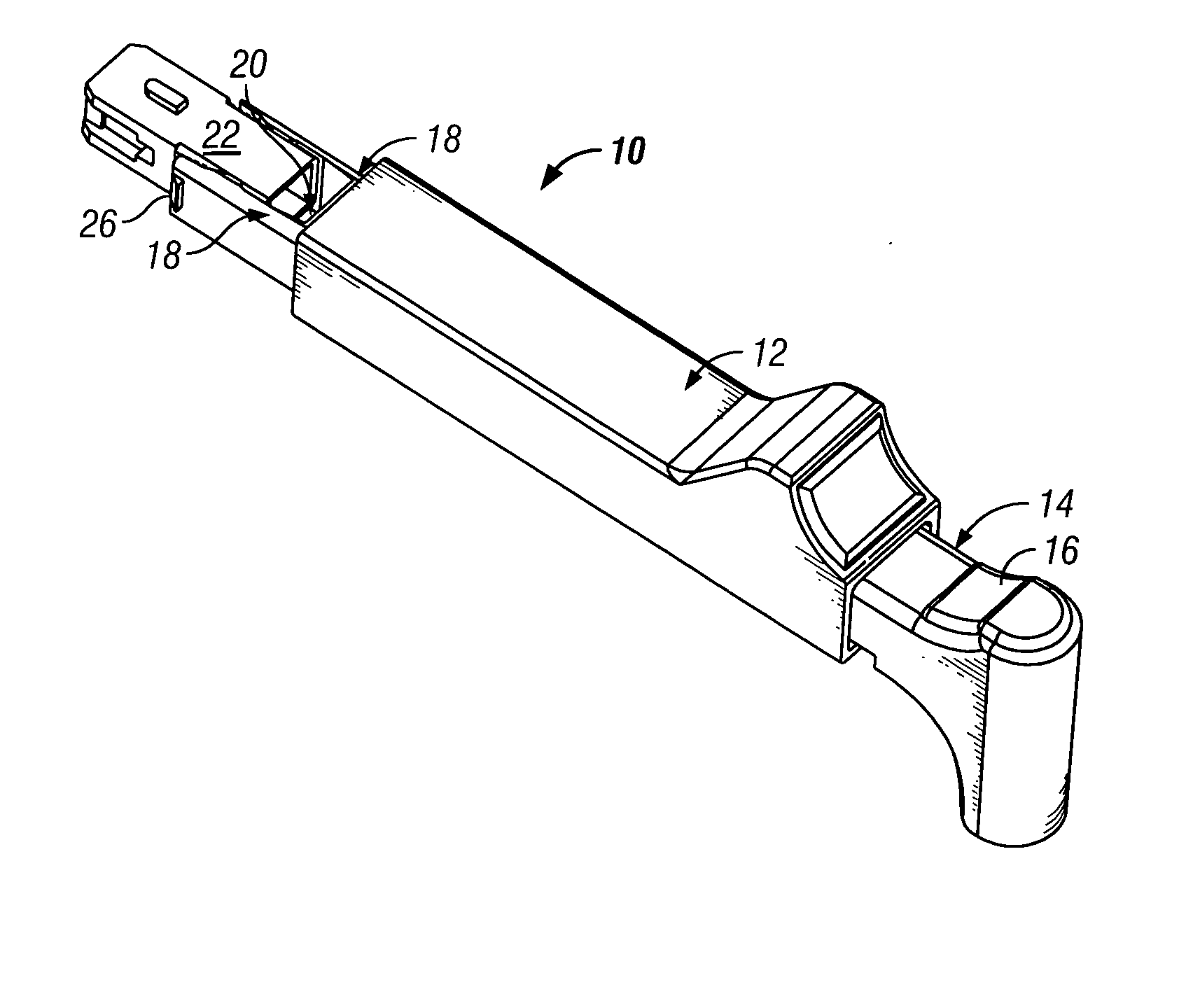

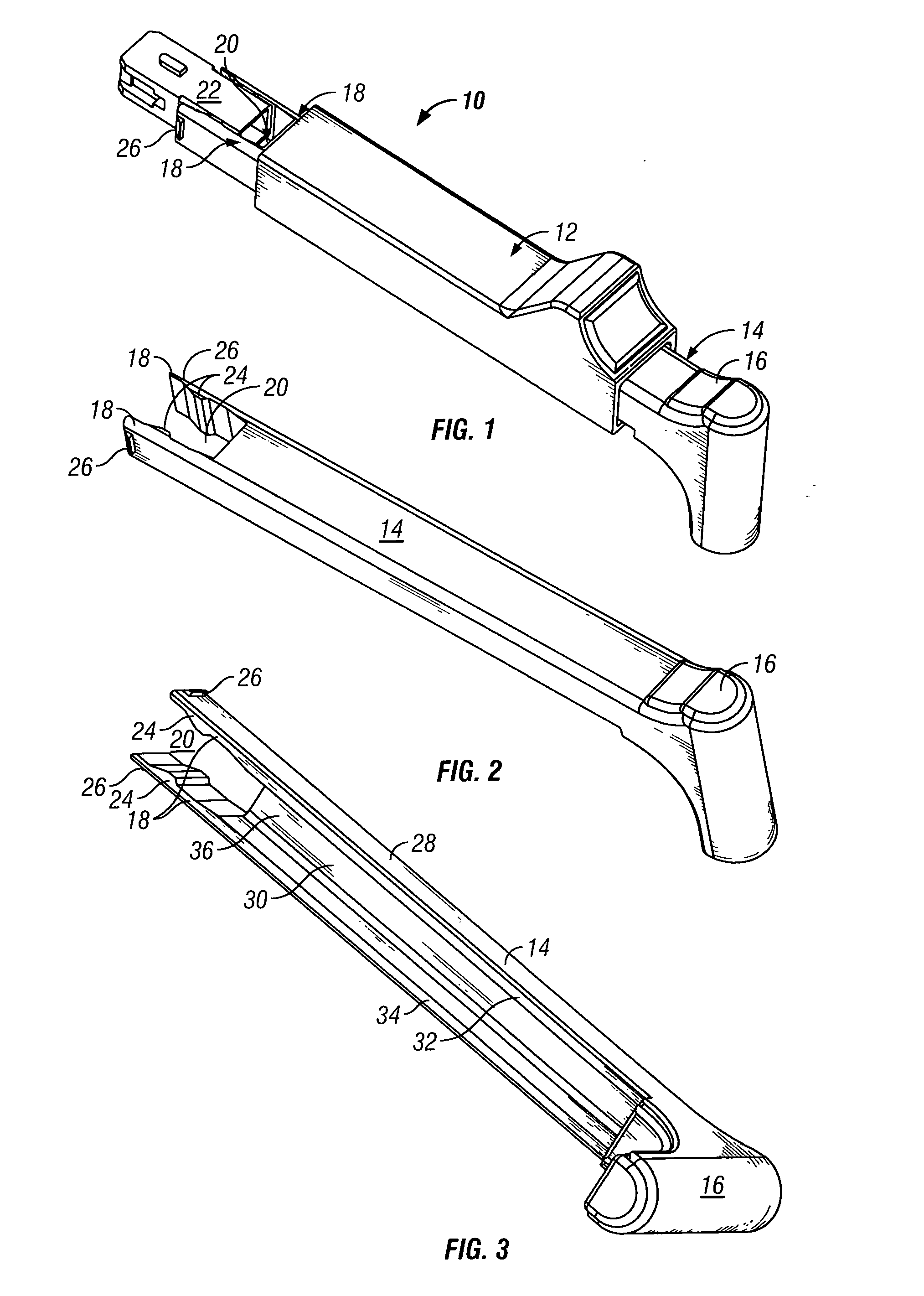

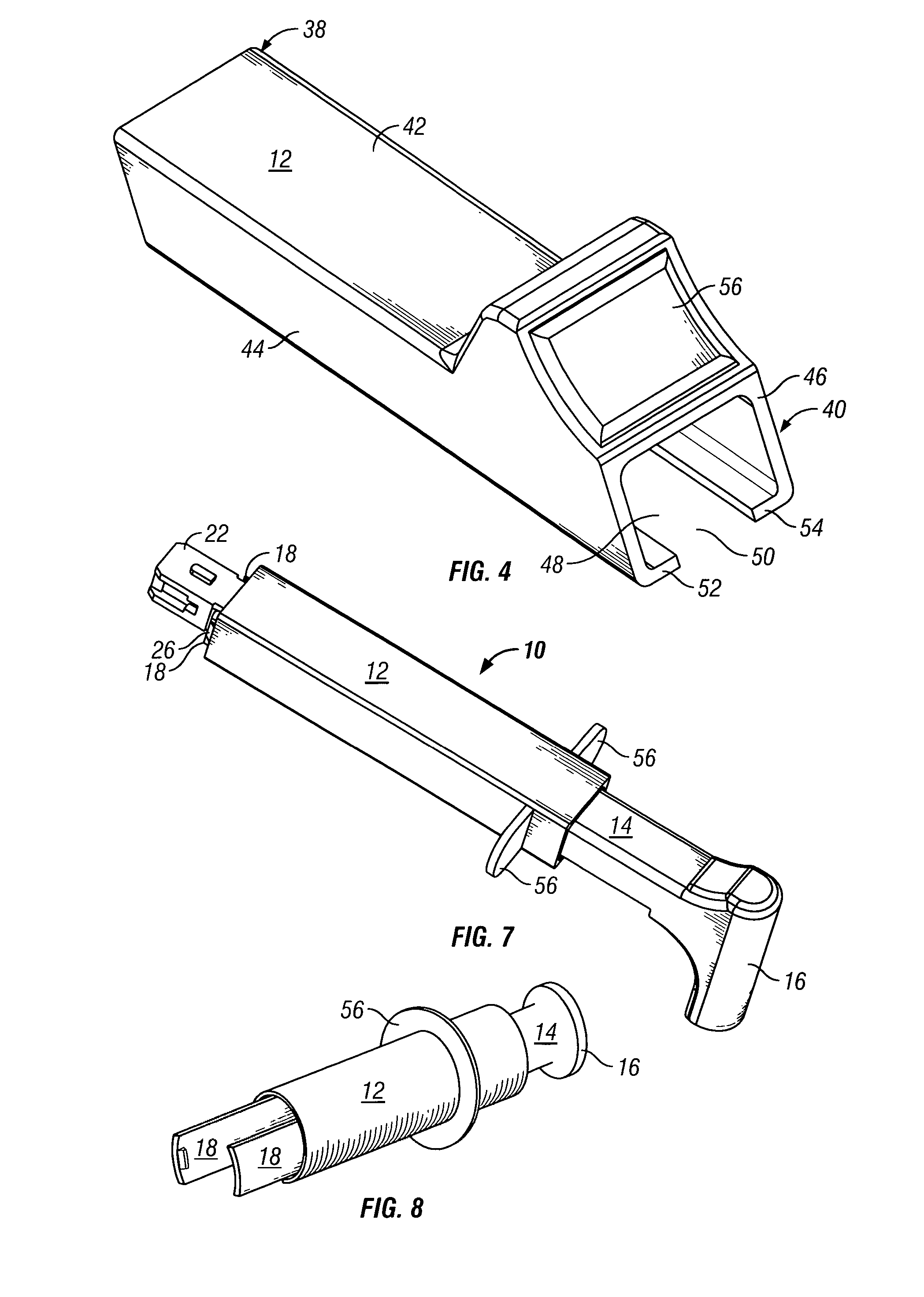

[0015] A connector coupling / decoupling tool 10 (hereinafter “connector tool”) according to the present invention comprises a sleeve 12 that is capable of sliding along an elongated gripper 14. Gripper 14 has a handle 16 at one end and fingers 18 at a distal end from handle 16. As shown in FIG. 1, fingers 18 form connector slot 20 spaced to engage connector 22. An embodiment of gripper 14 is shown g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com