MIS semiconductor device and method of fabricating the same

a semiconductor device and semiconductor technology, applied in the direction of semiconductor devices, basic electric elements, electrical appliances, etc., can solve the problems of increasing the length of wiring, the inability to achieve, and thus to a greater variance of transistor characteristics, so as to suppress the short-channel effect and reduce the variance of channel length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0158] (First Embodiment)

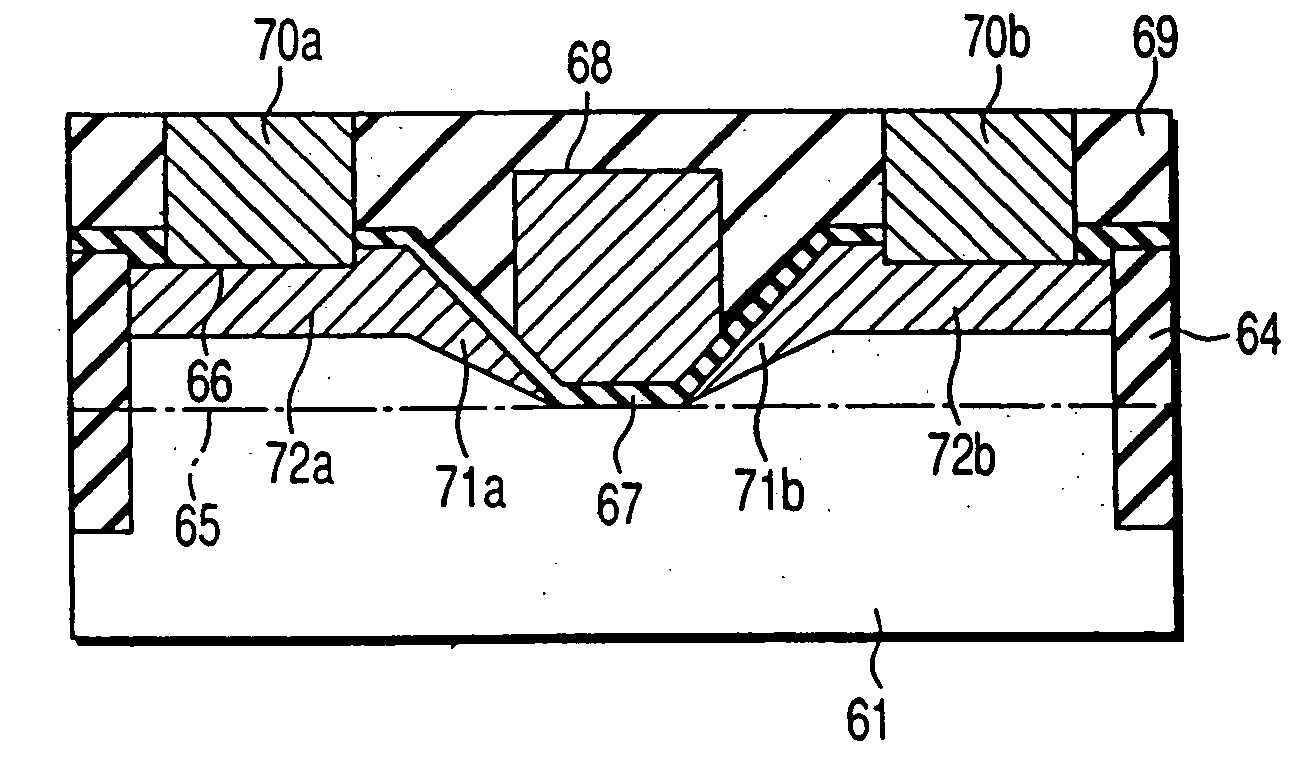

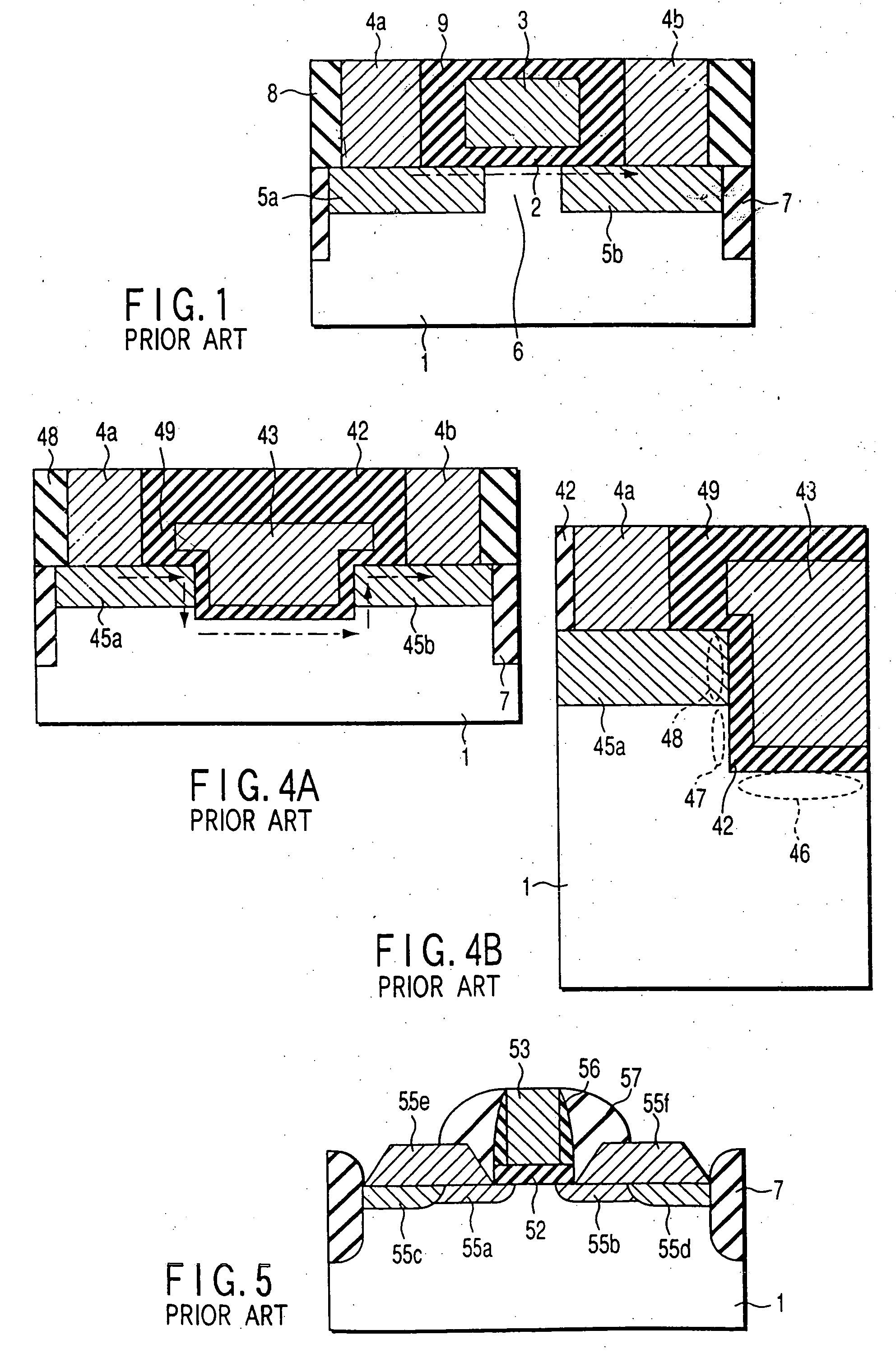

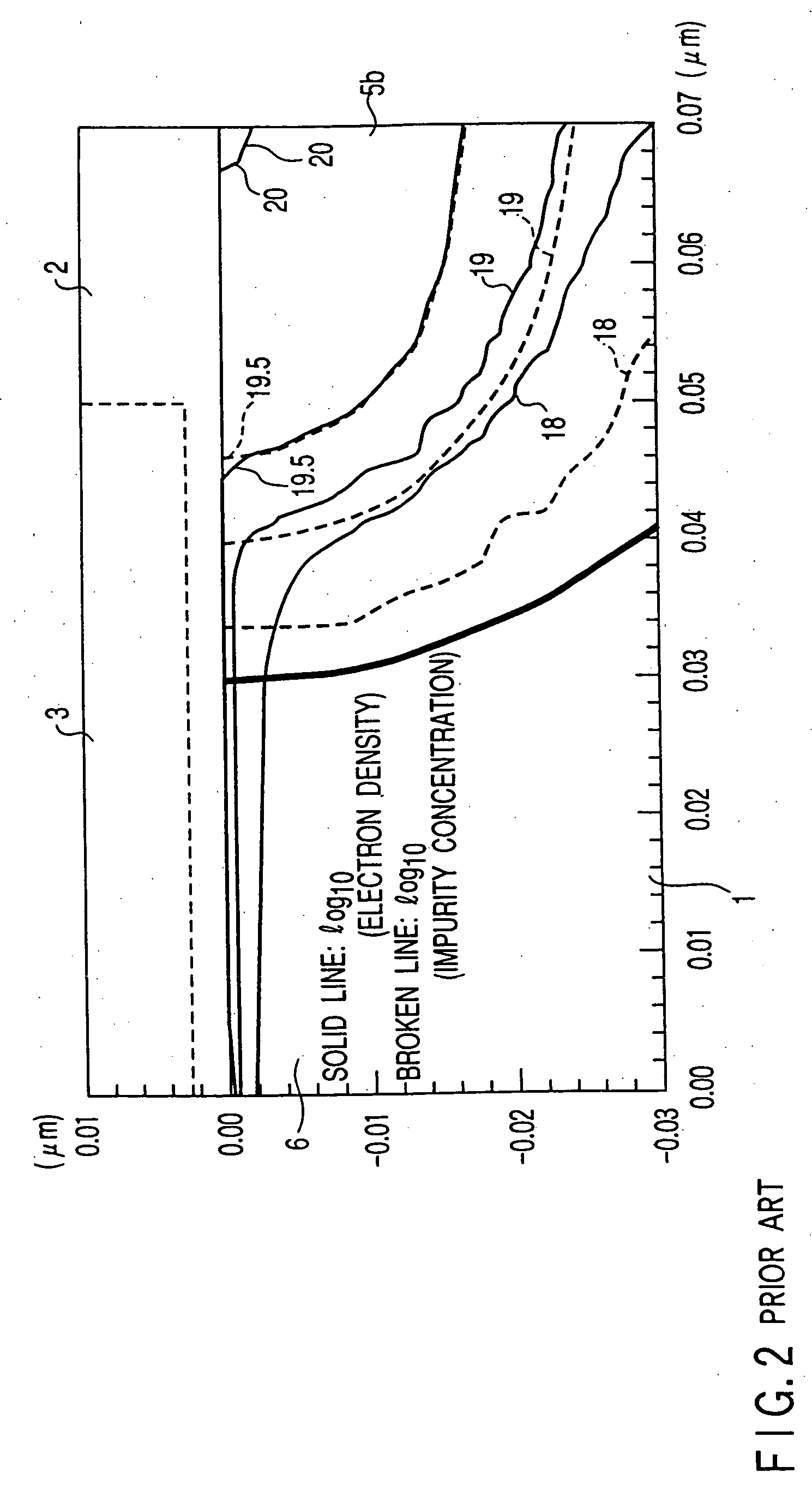

[0159]FIGS. 6A to 9 are views for describing a semiconductor device (concave-type MIS transistor) according to a first embodiment of the invention. FIGS. 6A to 6D and FIG. 9 are views for describing the structure of the semiconductor device according to this embodiment, and FIGS. 7A to 7D and FIGS. 8A to 8D are cross-sectional views showing manufacturing steps of the semiconductor device. FIG. 6A is a plan view of the semiconductor device. FIG. 6B is a cross-sectional view taken along line 6A-6A′ in FIG. 6A. FIG. 6C is a cross-sectional view taken along line 6B-6B′ in FIG. 6A, and FIG. 6D is a cross-sectional view taken along line 6C-6C′ in FIG. 6A. This embodiment is directed to an n-channel MIS transistor. If the conductivity types of respective structural portions are reversed, the following description will apply to a p-channel MIS transistor.

[0160] In FIG. 6B, numeral 61 denotes a p-type silicon substrate using a (100) plane, and its impurity concentra...

second embodiment

[0186] (Second Embodiment)

[0187]FIGS. 10A to 10E are cross-sectional views illustrating steps of manufacturing a transistor structure according to a second embodiment of the invention, wherein the transistor structure has a channel bottom surface with a radius of curvature. In this embodiment the distance between the gate electrode and the contact portion on the mask plane is zero and the contact portion is formed on the inclined source / drain in a self-alignment manner with respect to the gate electrode.

[0188] A description will now be given of a method of manufacturing a concave-type MIS transistor according to the present embodiment.

[0189] A SiO2 film 91 which is 0.02 μm thick is formed on a silicon substrate 61 in an active region. An Si3N4 film 101 which is 0.5 μm thick is then deposited. Using a desired photoresist pattern (not shown) as a mask, an opening is formed in the Si3N4 film 101. Subsequently, as shown in FIG. 10A, using the Si3N4 film 101 as a mask, the silicon subs...

third embodiment

[0203] (Third Embodiment)

[0204]FIG. 11 is a cross-sectional view showing the whole structure of a semiconductor device according to a third embodiment of the present invention. The semiconductor device of this embodiment is a modification of the first embodiment, wherein impurity regions 121a and 121b are added to the first source diffusion layer 71a and first drain diffusion layer 71b by controlling the conditions for the ion implantation 101 shown in FIG. 8B (first embodiment) or the subsequent activation anneal.

[0205] As is shown in FIG. 11, corner portions of the channel plane 65 are covered by the first source diffusion layer 71a and first drain diffusion layer 71b, and thus the impurity regions 121a and 121b covering the corner portions are formed. In this structure, the carrier density of the corner portions of the channel plane 65, which are continuous with the accumulation layers formed in the first source diffusion layer 71a and first drain diffusion layer 71b at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com