Accumulator with pickup tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

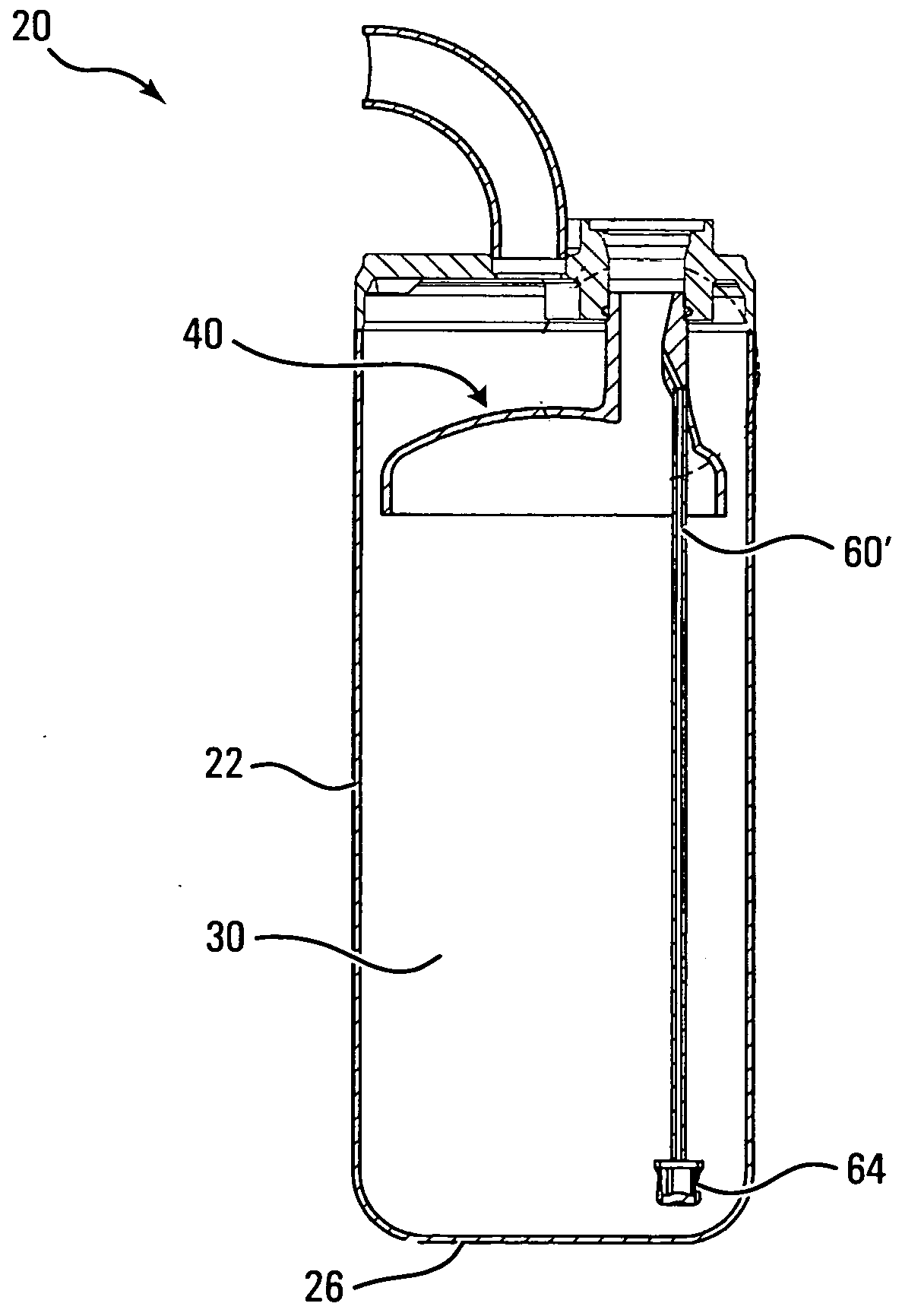

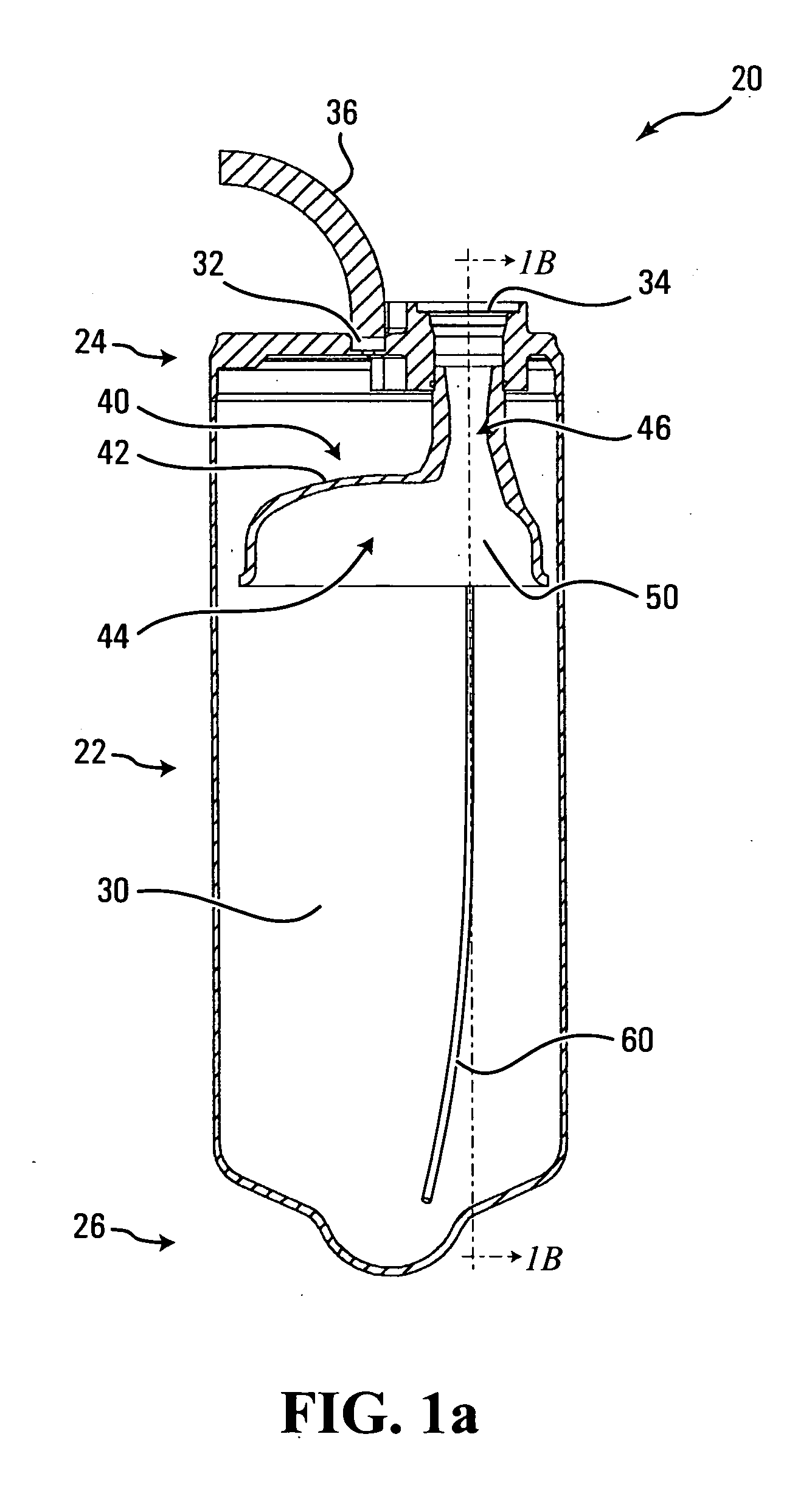

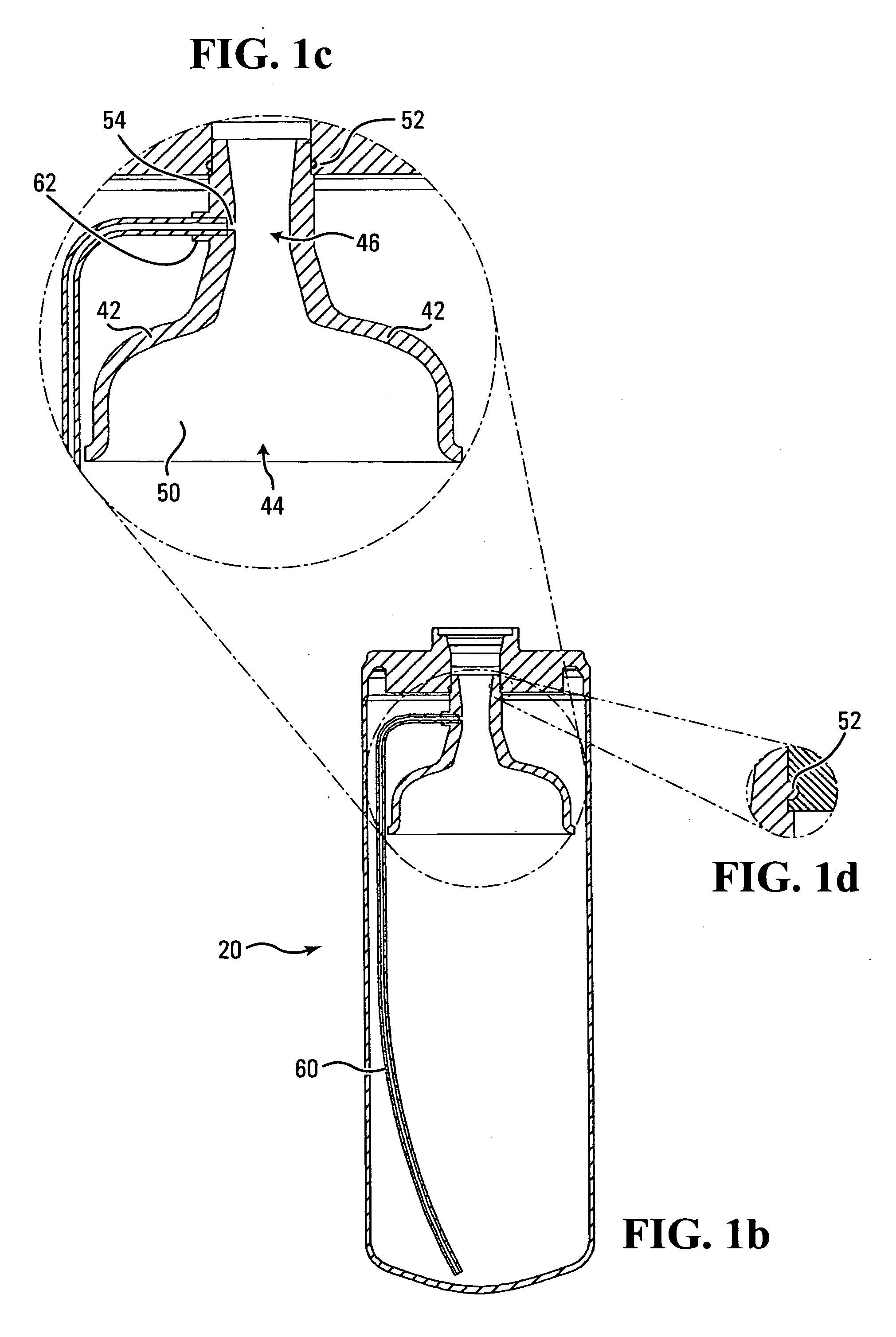

[0054] A sectional side view of an accumulator 20 is shown in FIG. 1a. The accumulator has a body 22 and a cap 24.

[0055] The body 22 is generally cylindrical, with an open top end, and a closed bottom end or floor 26. The bottom end 26, in this embodiment, is sloped inwards, with a depression or sump around and near the center. The volume within the accumulator 20 may be referred to as a reservoir 30.

[0056] The cap 24 is formed to fit securely over the top end of the body 22. The cap 24 has in inlet hole (or inlet port or inlet opening) 32 and an outlet hole (or outlet port or outlet opening) 34 formed therein. An inlet line 36 is secured to the inlet hole 32. The cap 24 is formed of a suitable material, such as aluminum, for example.

[0057] The cap 24 is secured to the body 22 by welding, swaging, heat or ultrasonic staking, gluing or some other suitable technique.

[0058] A deflector 40 is secured to (or in communication with) the outlet port 34. The deflector 40 has an exterior ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com