Continuous dissolving device, continuous dissolving method, and gas-dissolved water supply

a technology of continuous dissolution and continuous dissolution, which is applied in the direction of dissolving, machine/engine, and the nature of treatment water, etc., can solve the problems of inability to achieve desirable results, fluctuation of the concentration of gas or chemical in the produced functional water, and considerable tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

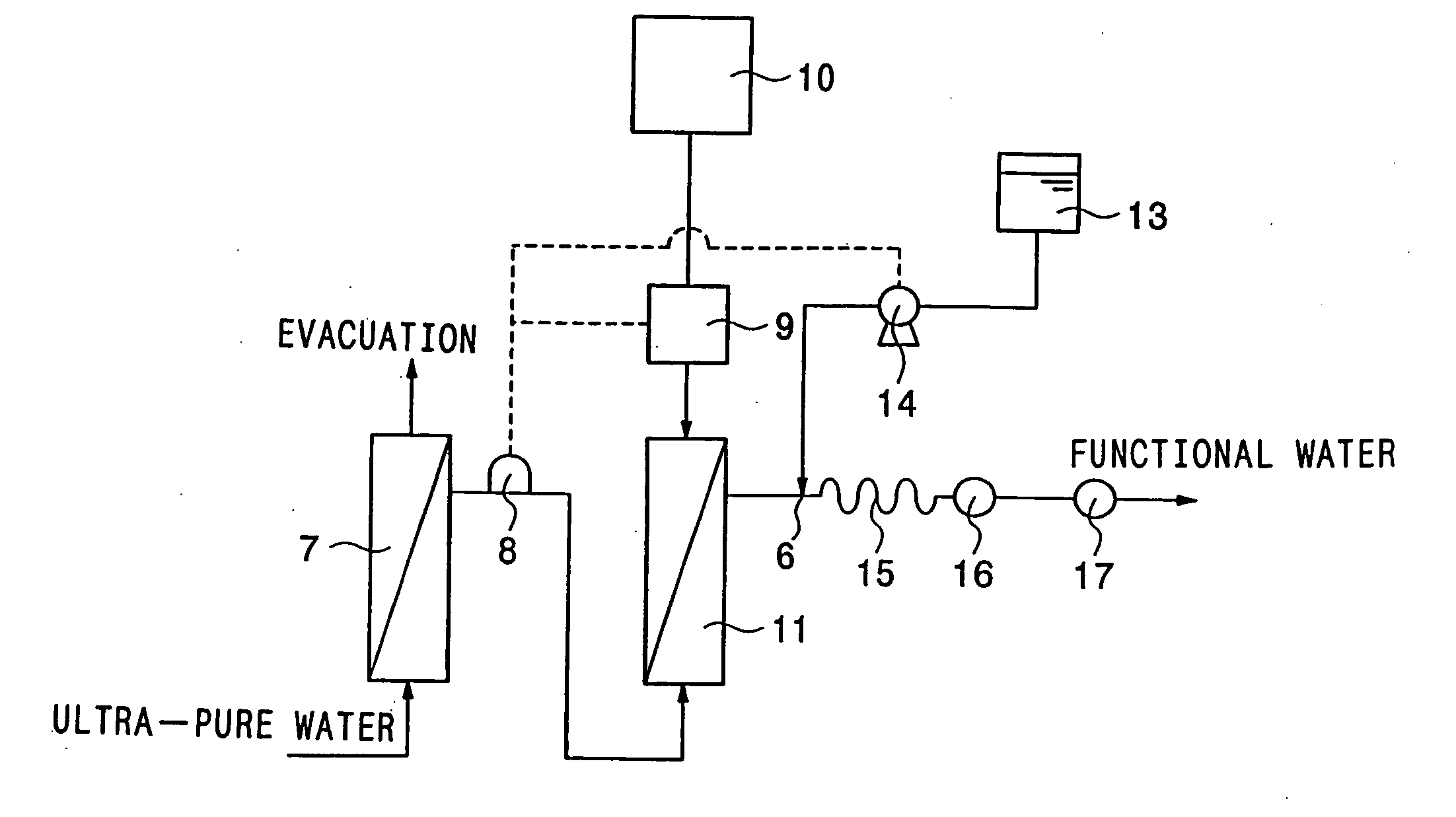

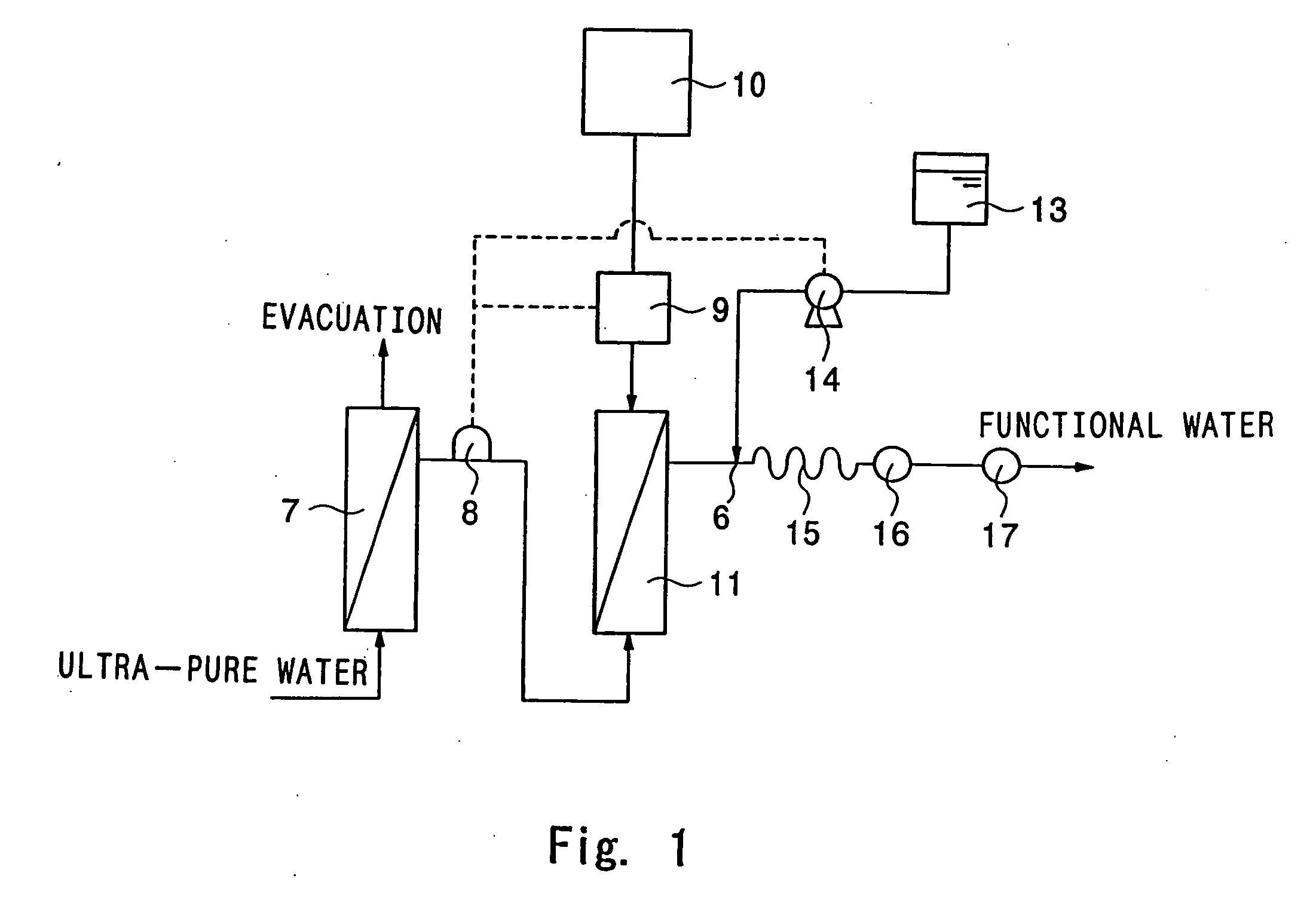

[0057] Hydrogen-dissolved water was produced by using the apparatus for producing a functional cleaning water shown in FIG. 1. The used ultra-pure water contained 10 to 18 ppm of dissolved nitrogen gas and 0.01 to 2 ppm of dissolved oxygen gas. The ultra-pure water was passed through a membrane apparatus for degassing and degassed until the concentration of the dissolved nitrogen gas was 1.5 ppm or smaller and the concentration of the dissolved oxygen gas was 0.5 ppm or smaller. The degassed ultra-pure water was supplied to the dissolution portion. The signal of the flow rate of the ultra-pure water was output from the Karman's vortex flow meter and the amount of supply of hydrogen gas was controlled proportionally to the flow rate of the ultra-pure water by the mass flow controller. Hydrogen was dissolved into the ultra-pure water at the dissolution portion having a module having a built-in gas-permeating membrane and hydrogen-dissolved water was produced.

[0058] The production of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com