Lithium-iron disulfide primary battery

a technology of lithium iron disulfide and primary battery, which is applied in the direction of non-aqueous electrolyte cells, cell components, electrochemical generators, etc., can solve the problems that the addition of potassium salt cannot achieve the satisfactory effect of suppressing the elevation of open circuit voltage and poor solvent power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

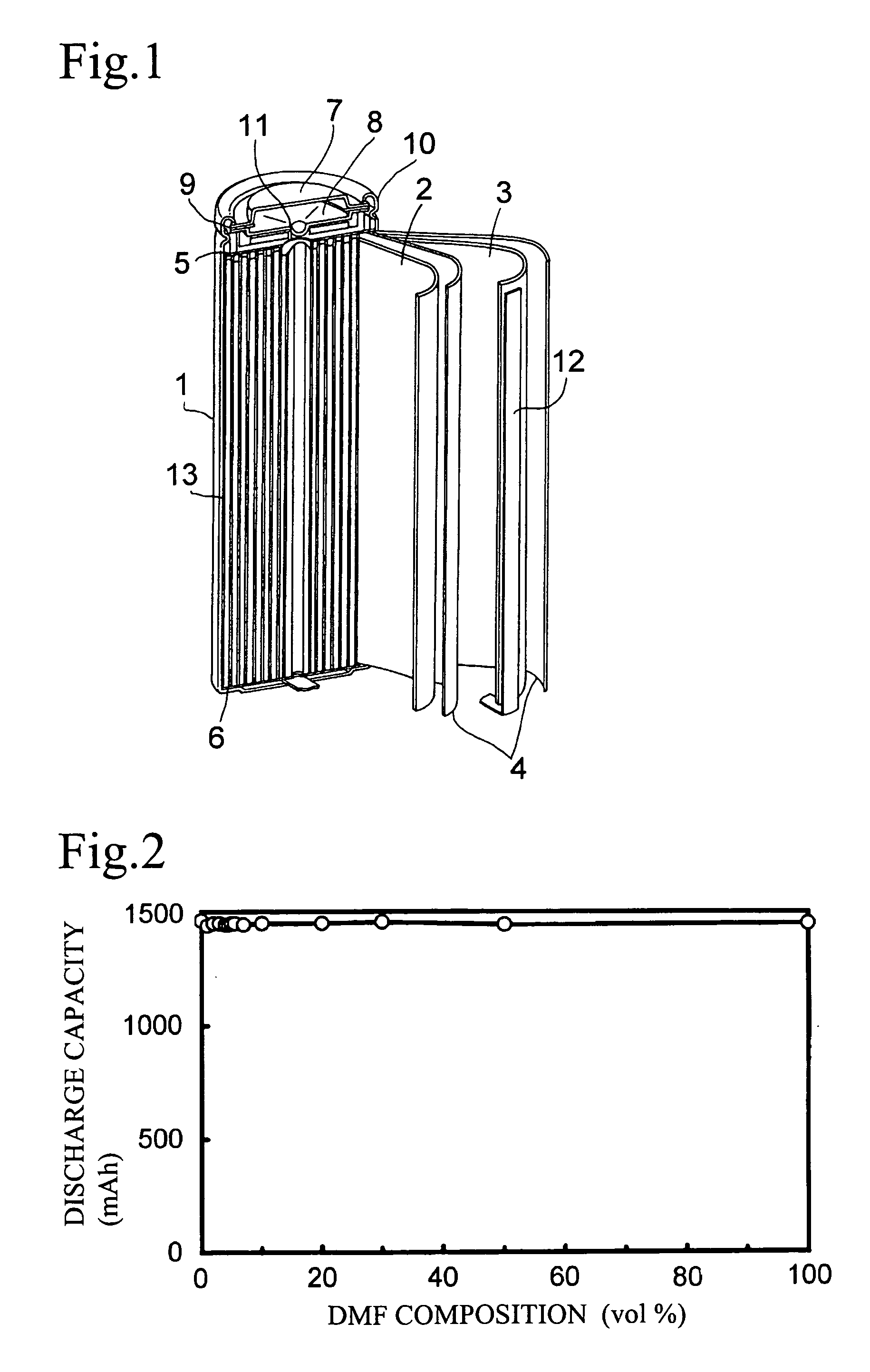

example 1

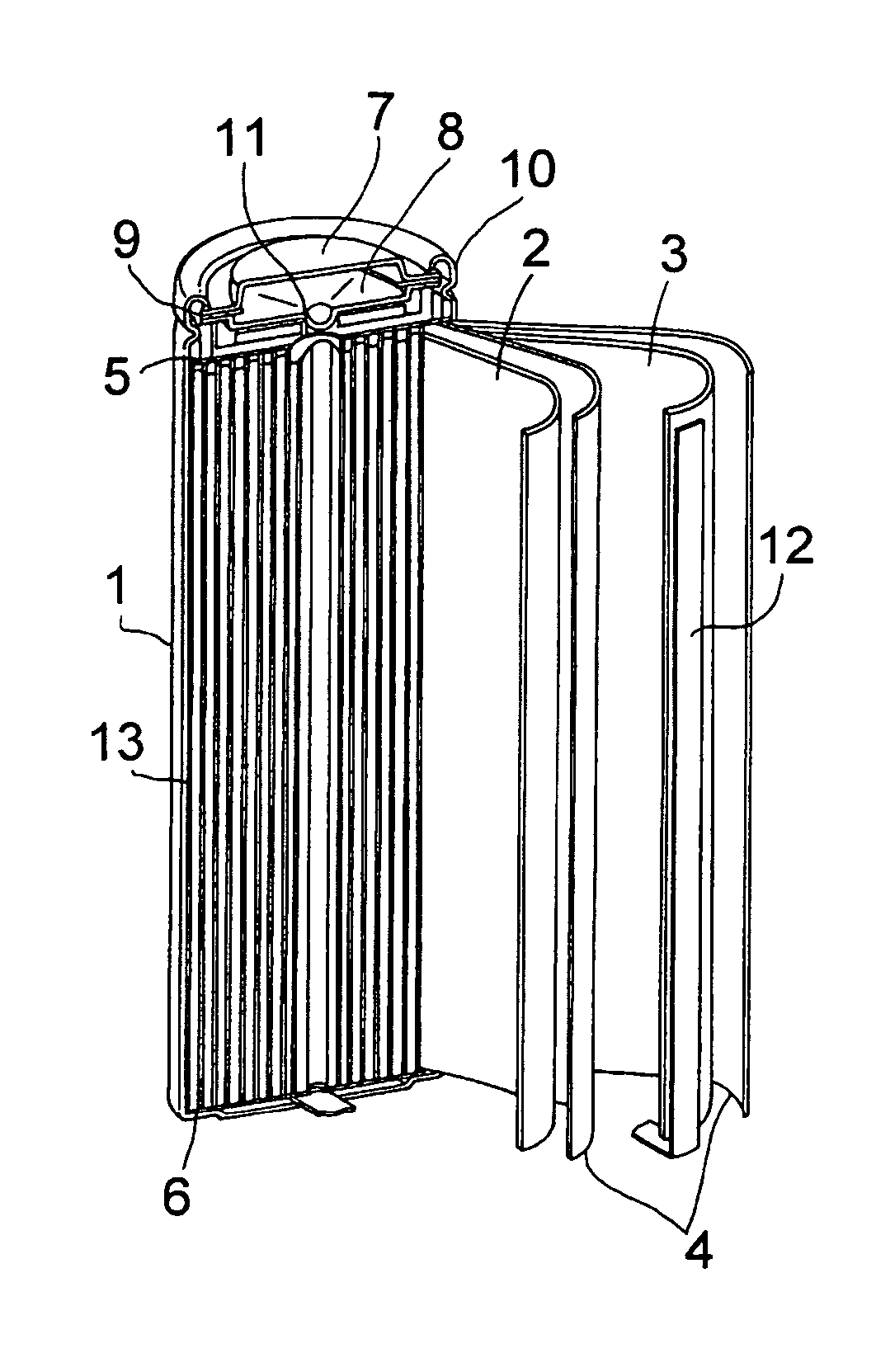

[0082] First, 98.0% by weight of iron disulfide as a cathode active material, 1.0% by weight of carbon powder as an electrical conductor, and 1.0% by weight of a binder (dry weight) were mixed together, and satisfactorily dispersed in N-methyl-2-pyrrolidone (NMP) as a solvent to prepare a cathode composition slurry. As the iron disulfide which is a cathode active material, “HG-PPC #250”, manufactured and sold by Dowa Mining Co., Ltd., was used. As the carbon powder, “DENKA BLACK HS-100 (powdery)”, manufactured and sold by Denki Kagaku Kogyo Kabushiki Kaisha, was used, and, as the binder, “BM-500B”, manufactured and sold by ZEON CORPORATION., was used.

[0083] Then, the cathode composition slurry was applied to both surfaces of a cathode current collector, and dried at 120° C. for 2 hours to evaporate NMP, followed by compression molding under a constant pressure, to prepare a strip positive electrode 2. As the cathode current collector, a strip aluminum foil having a thickness of 20 ...

example 14

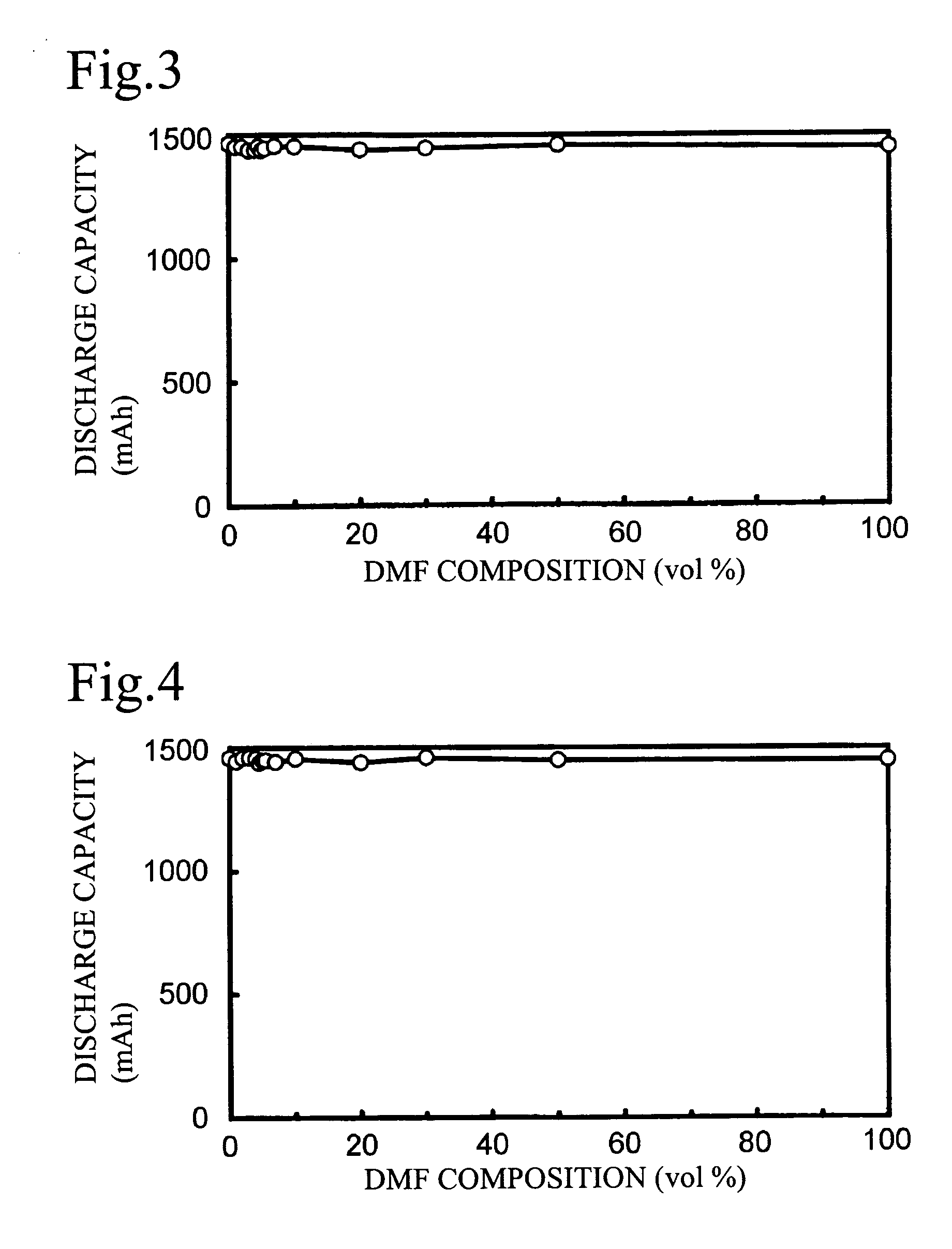

[0090] Substantially the same procedure as in Example 1 was repeated except that, instead of the mixed solvent including 1.0% by volume of N,N-dimethylformamide (DMF) as analkylamide solvent and 99.0% by volume of 1,2-dimethoxyethane (DME) as a chain ether solvent, a mixed solvent including 1.0% by volume of N,N-dimethylformamide (DMF) as an alkylamide solvent and 99.0% by volume of 1,3-dioxolane (DOL) as a cyclic ether solvent was used to obtain a lithium-iron disulfide primary battery.

example 27

[0093] Substantially the same procedure as in Example 1 was repeated except that, instead of the mixed solvent including 1.0% by volume of N,N-dimethylformamide (DMF) as an alkylamide solvent and 99.0% by volume of 1,2-dimethoxyethane (DME) as a chain ether solvent, a mixed solvent including 1.0% by volume of N,N-dimethylformamide (DMF) as an alkylamide solvent and 99.0% by volume of methyl propionate (MP) as a chain carboxylic acid ester solvent was used to obtain a lithium-iron disulfide primary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge voltage | aaaaa | aaaaa |

| open circuit voltage | aaaaa | aaaaa |

| open circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com