Packaging

a technology for packaging and packaging components, applied in the field of packaging, can solve the problems of difficult inspection of goods or labeling inside the packaging, work against electrostatic protection, and risky well-being of some goods such as electronic components and circuits or some medical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

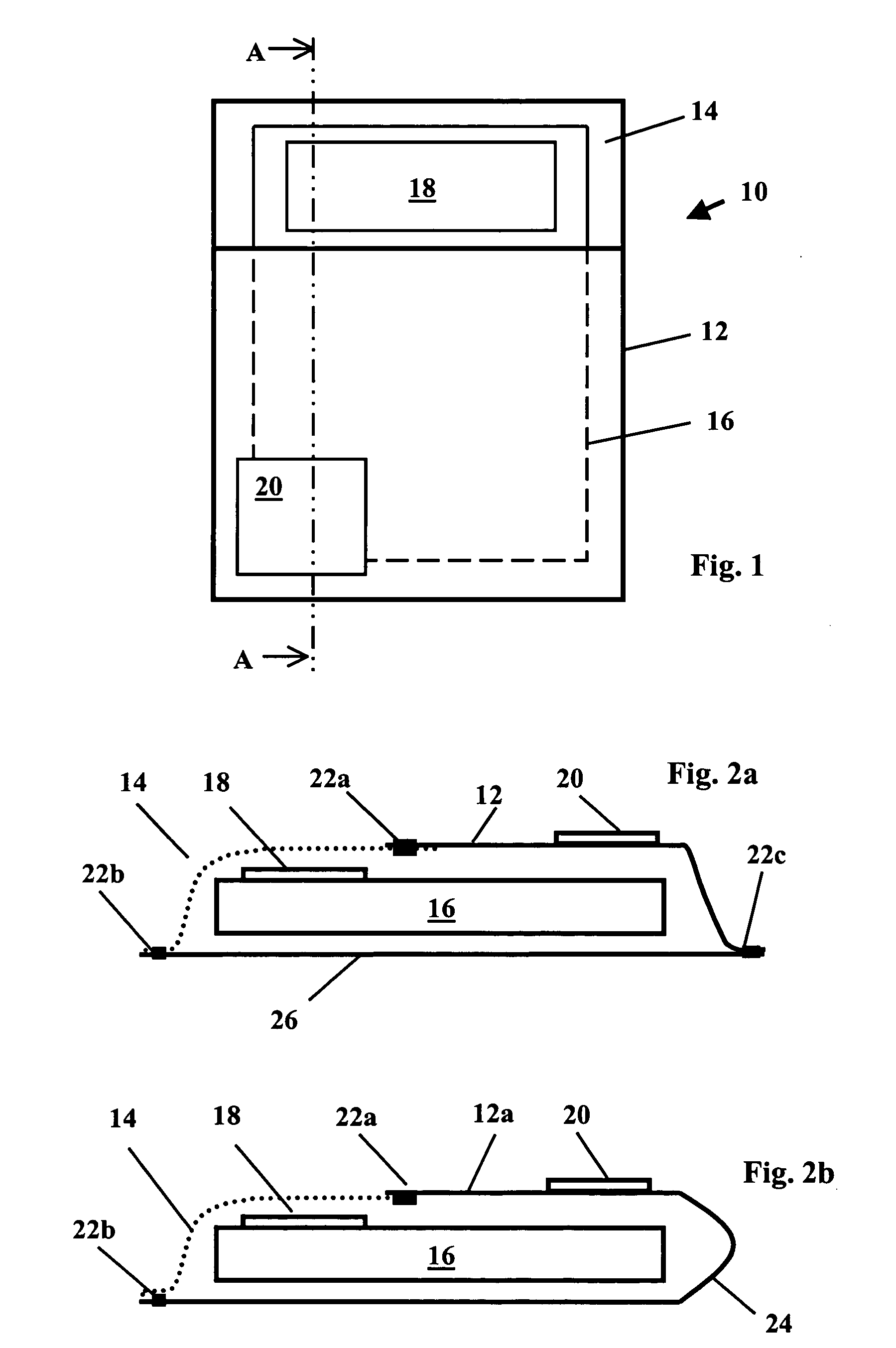

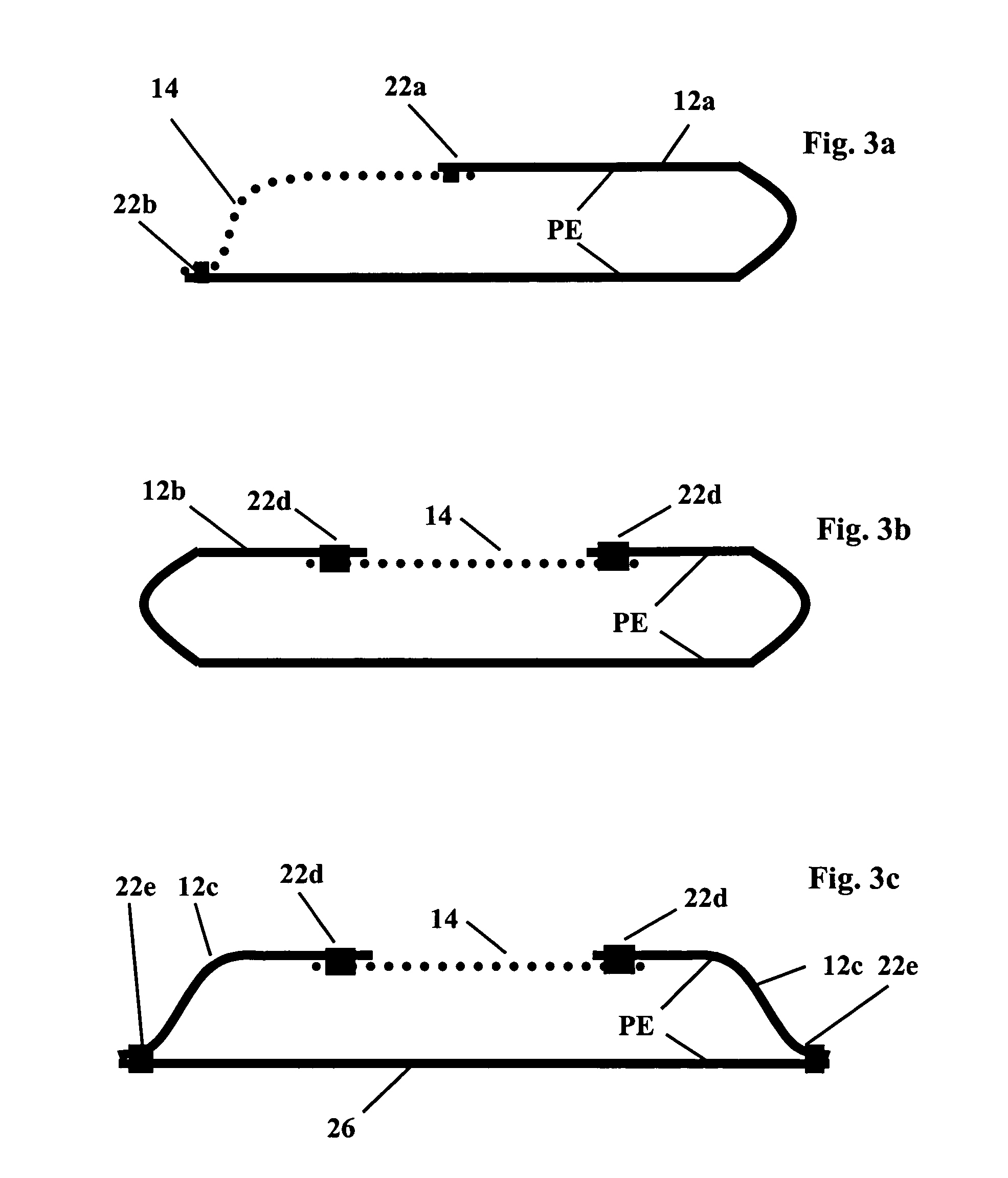

[0057] the invention is disclosed with reference now also to FIG. 3b. This embodiment is a variation of the arrangement described above in relation to FIGS. 2b and 3a, in that a metal laminate sheet 12b is folded or wrapped around itself on two ends or two sides, again such that the heat-sealable side (PE) is inboard of the package / bag. The window 14 is then hermetically sealed across an opening between the two edges of the sheet 12b by lines of heat-sealing 22d. The open and opposing ends of the package / bag thus formed can then be heat-sealed as appropriate for the goods being packaged. Examples of sealing techniques are discussed below with particular reference to FIG. 4c.

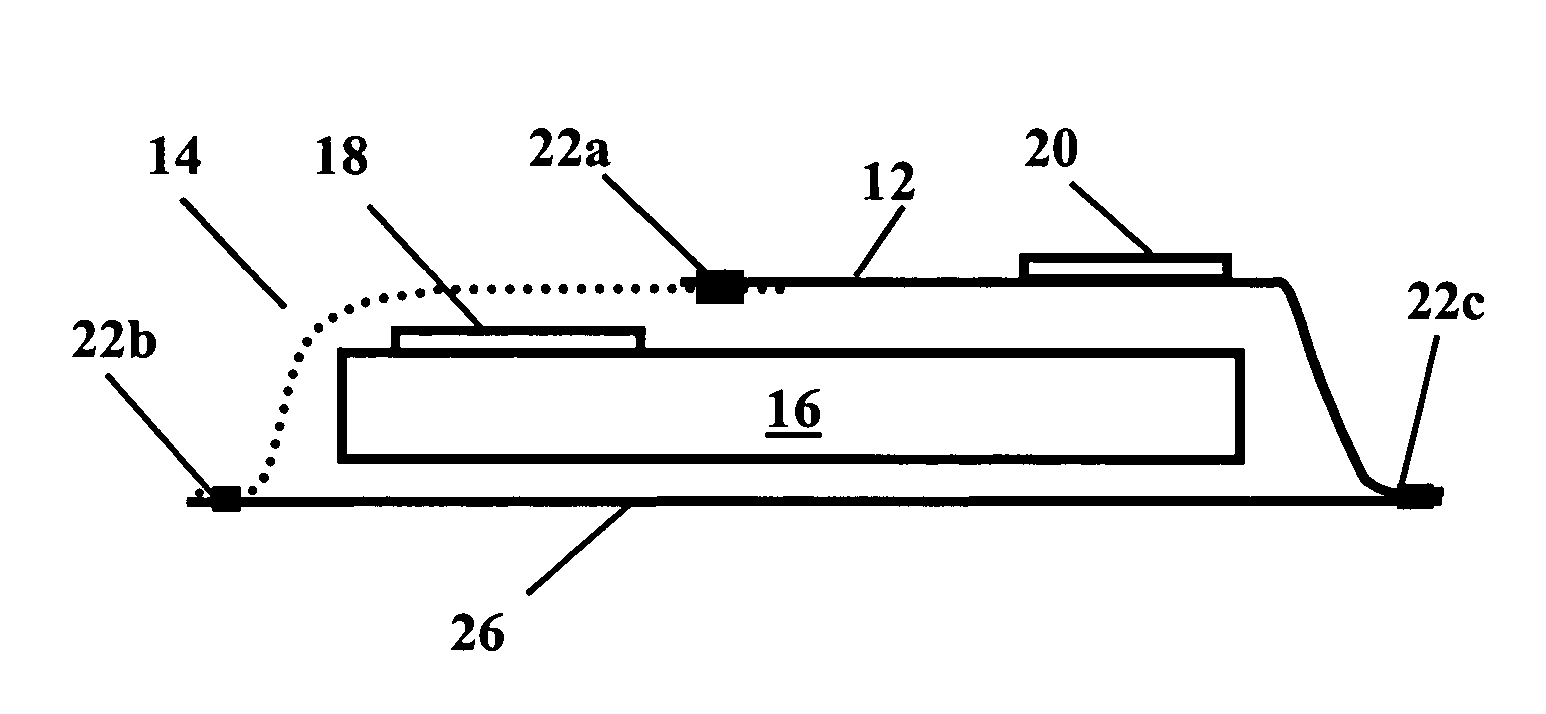

[0058] The structure of the second embodiment may be varied such that it is made from a series of one-time separate panels 12c, 14, 12c, 26. Initially, separate strips 12c of the metal film laminate are heat sealed 22d PE side down onto a strip 14 of the window sheet. This panel 12c, 14, 12c, referred to for con...

fourth embodiment

[0066] Referring to FIG. 6 a package 10 is in the form of a bag / envelope and comprises a body made of flexible sheet material in the form of a front panel 12 and a back panel 26. The material used to provide the back panel 26 is a flexible metal laminate as described above, comprising for example a 20 micron thick aluminum foil / film laminated in between a carrier ply on one side and a heat-sealable ply on the other side. The carrier ply may comprise a polyester material, preferably polyethylene terephthalate (PET), but may be made from other materials such as orientated polypropylene (OPP) and orientated polyamide (OPA). The heat-sealable ply may comprise for example polyethylene (PE).

[0067] The front panel 12 is made of a composite laminate. In one section of the front panel a translucent window 14 is defined which extends part of or all the way across the front panel 12. The window 14 comprises a portion of the composite laminate forming the front panel 12. The window section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductivity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com