Thrust pad assembly for ECP system

a thrust pad and assembly technology, applied in the field of electrochemical plating systems, can solve the problems of device failure or burn-in, complex interconnection of components in the circuit, and subjected to precise dimensional control, so as to reduce the quantity of metal electroplated onto the edge region, reduce the ohmic contact, and reduce the effect of pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

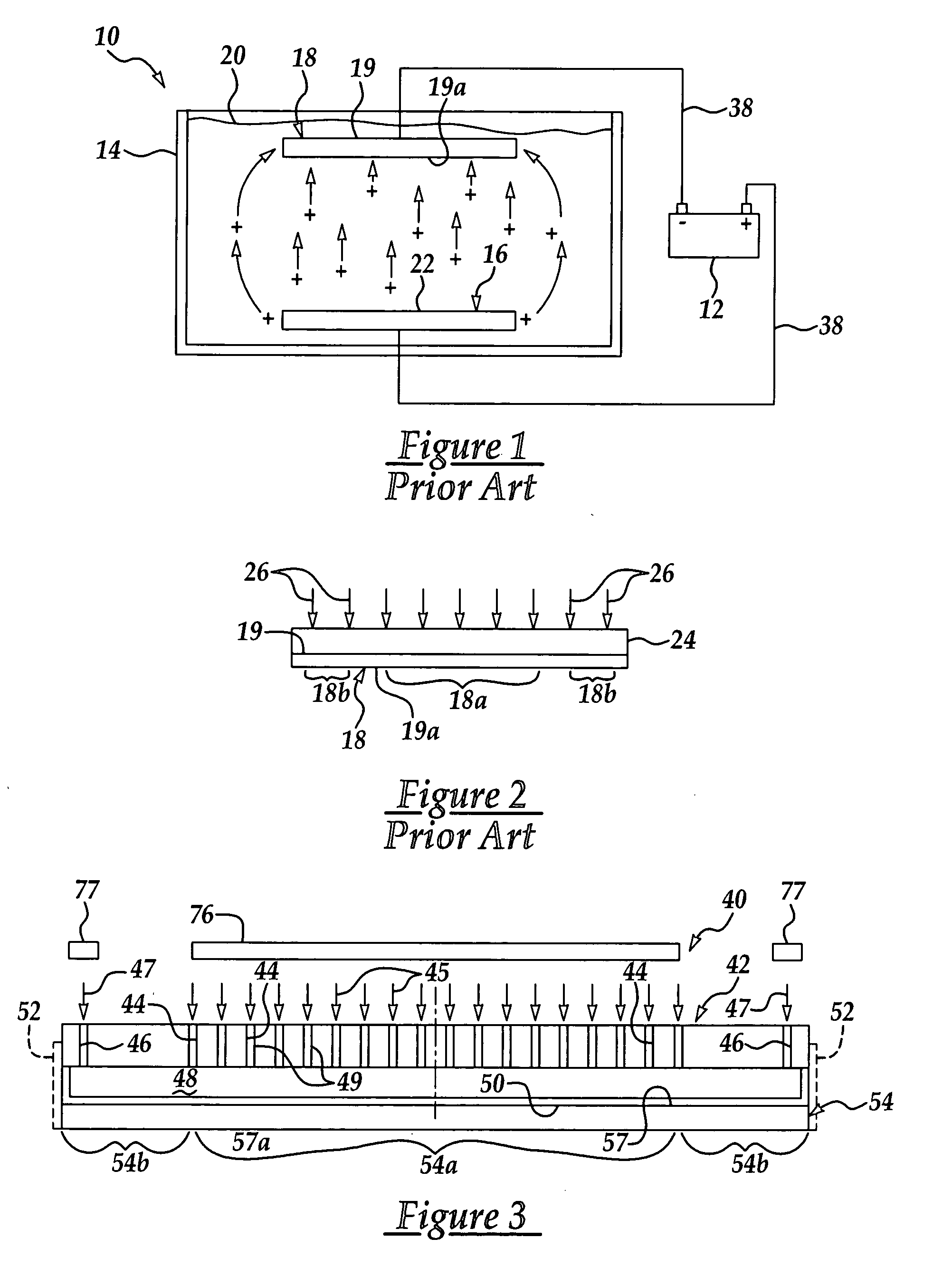

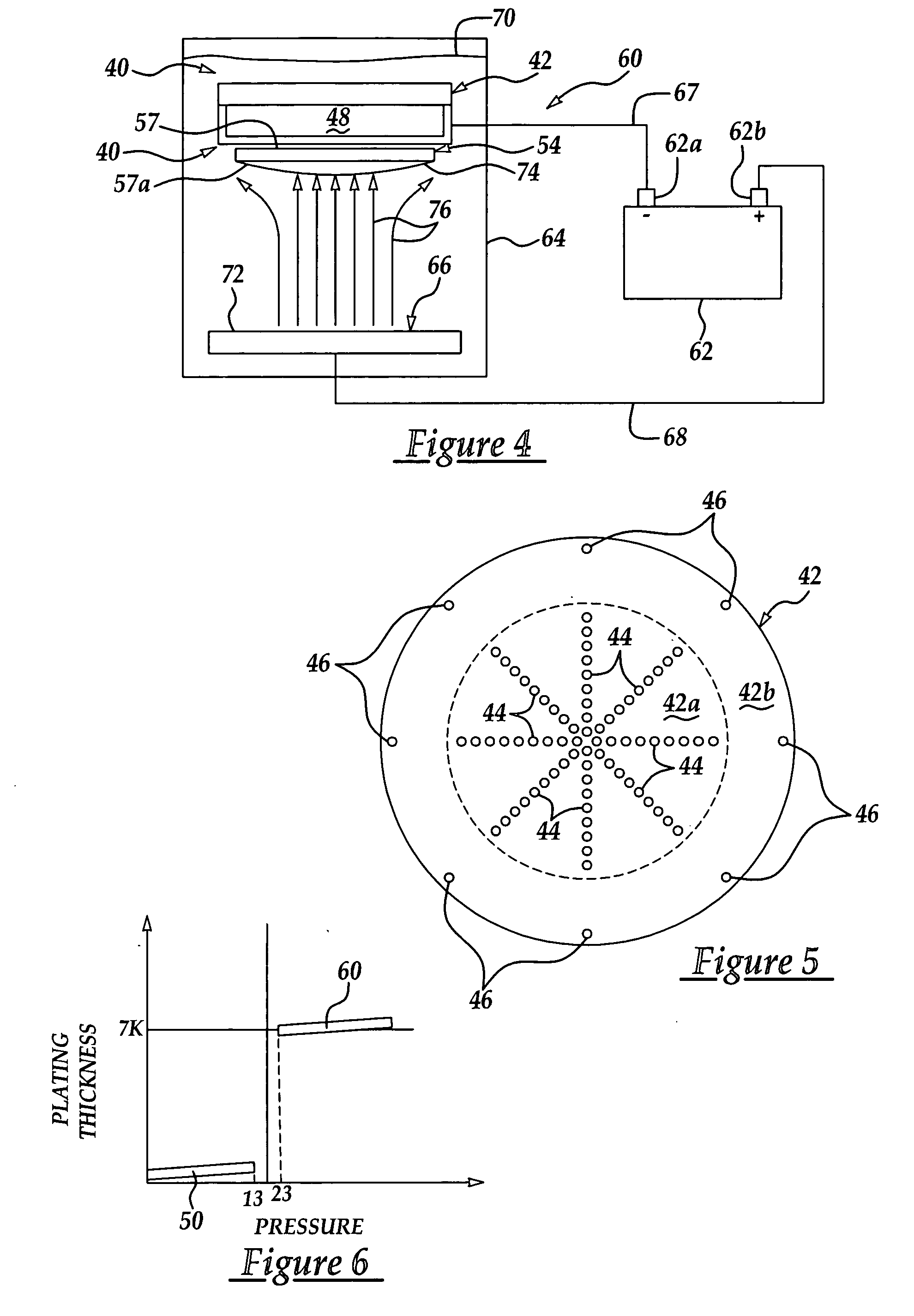

[0030] The present invention has particularly beneficial utility in the electroplating of copper or other metals onto a semiconductor wafer substrate in the fabrication of integrated circuits on the substrate. However, the invention is not so limited in application, and while references may be made to such semiconductor wafer substrate and integrated circuits, the invention may be more generally applicable to electroplating metals on substrates in a variety of industrial applications.

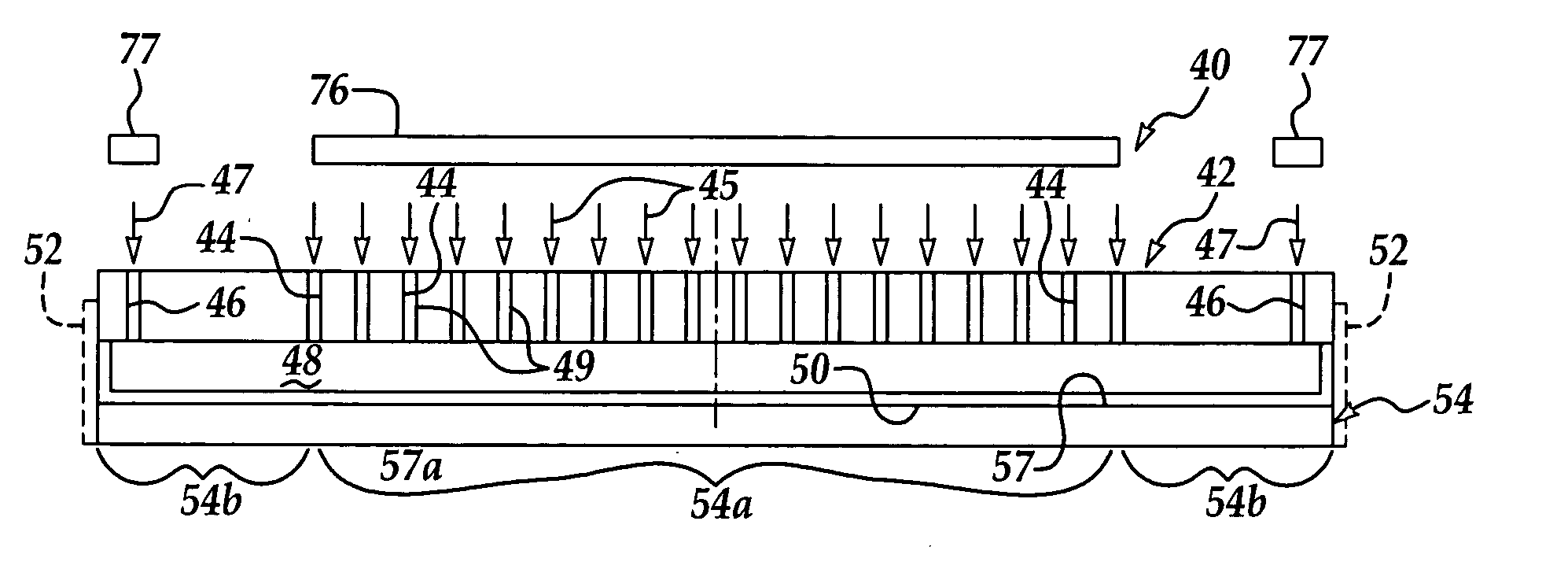

[0031] The present invention is generally directed to a new and improved thrust pad assembly which is suitable for preventing deposition of excess quantities of metal onto the edge or peripheral region of a substrate as copper or other metal is electroplated onto the substrate in the fabrication of semiconductor integrated circuits on the substrate. The thrust pad assembly eliminates the need for edge bevel cleaning or removal of excess metal from the edge region of the substrate after the electroplati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peripheral pressure | aaaaa | aaaaa |

| air pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com