Electro-optic displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

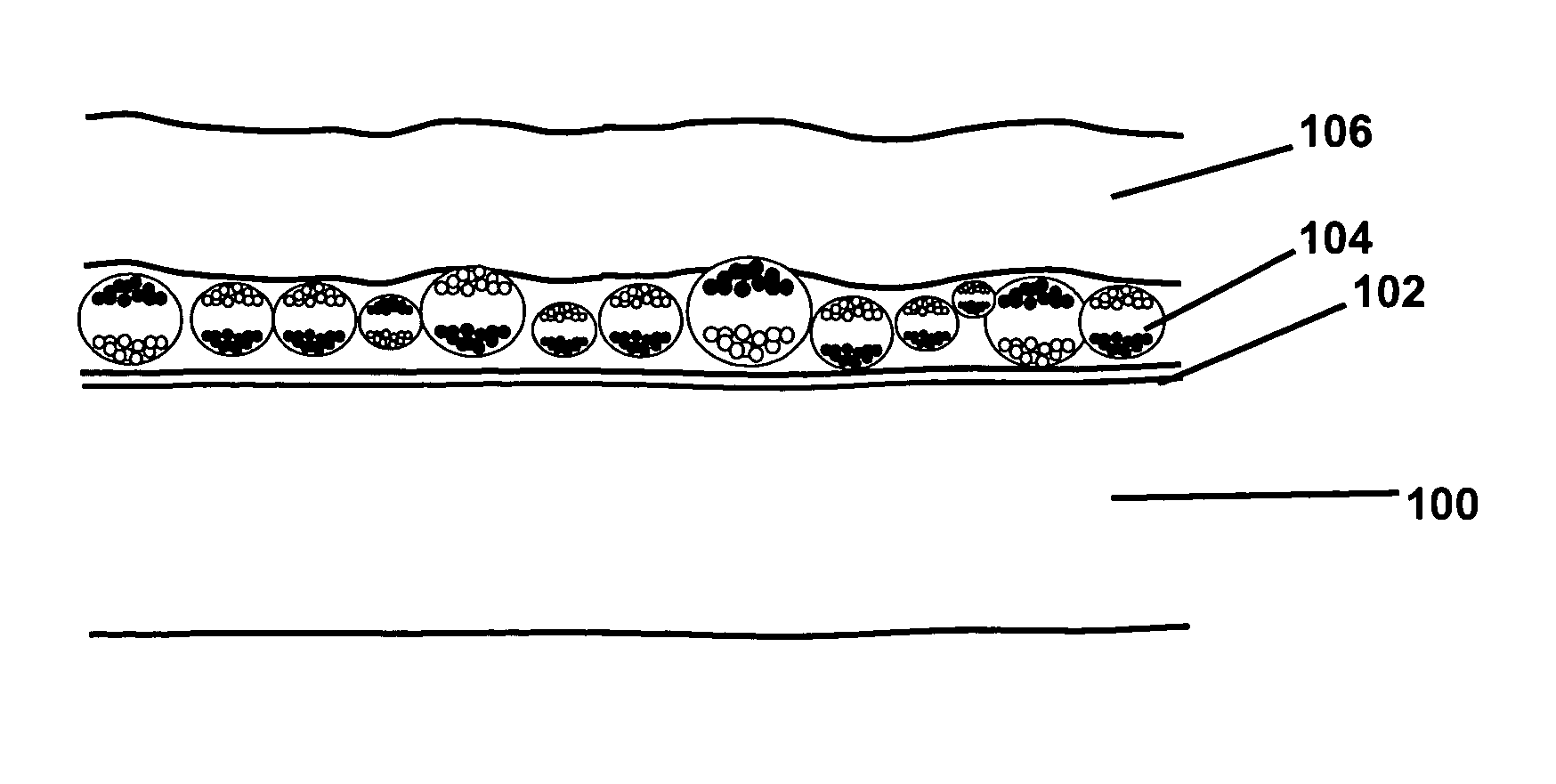

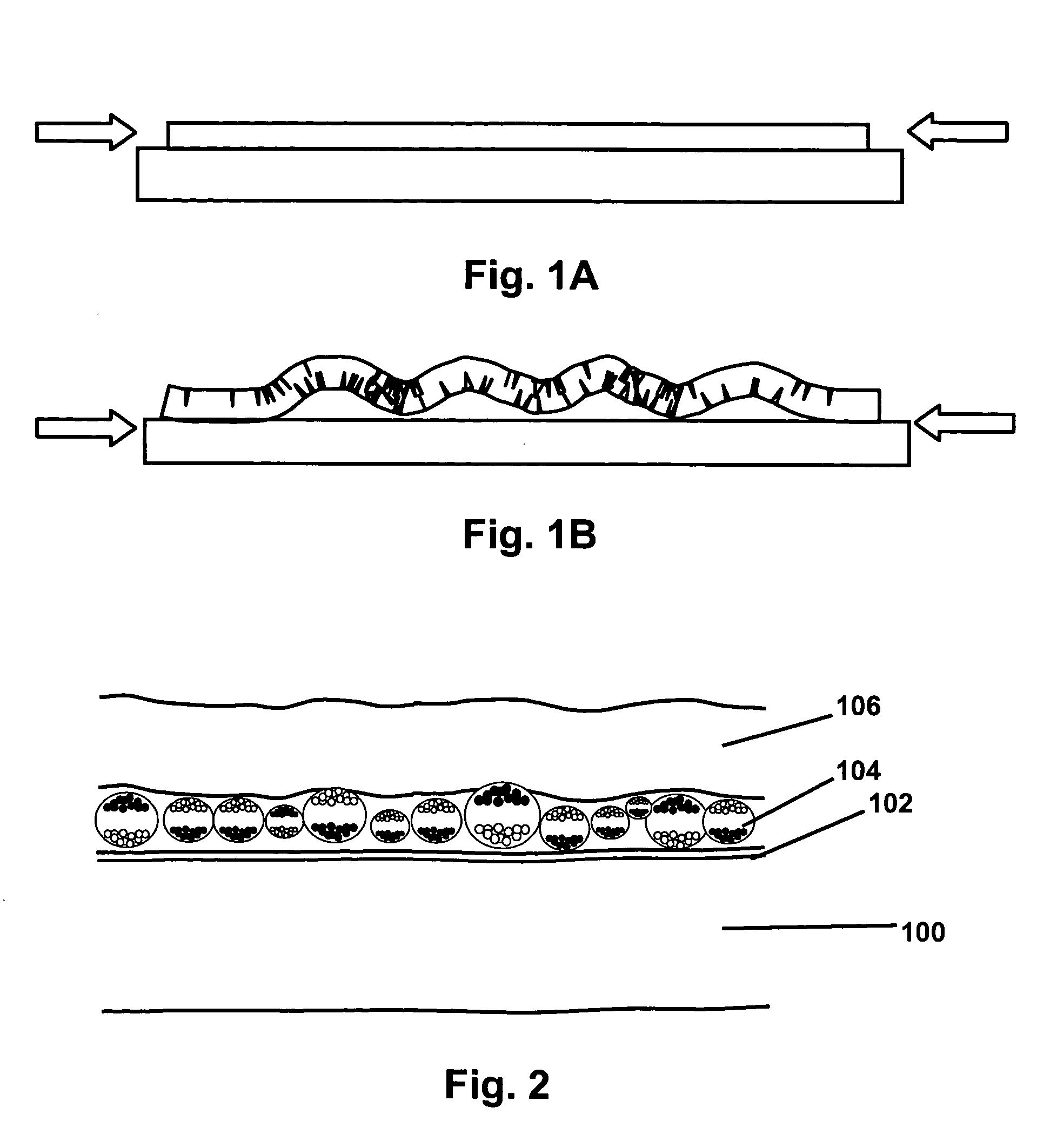

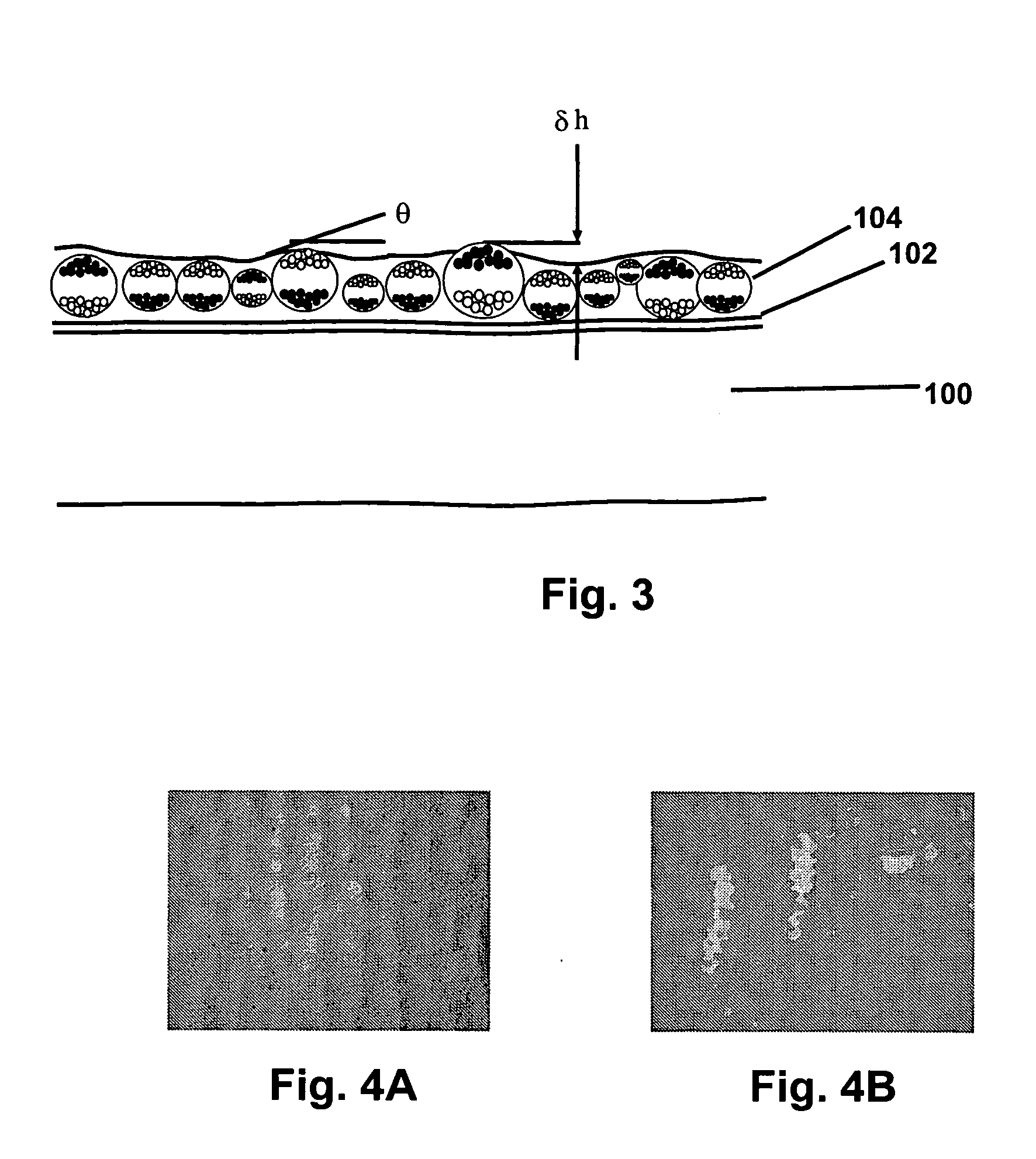

[0067] An internal phase was prepared comprising polymer-coated titania white particles and polymer-coated carbon black particles in a hydrocarbon suspending fluid. This internal phase was encapsulated in gelatin / acacia microcapsules substantially as described in Paragraphs [0069] to [0074] of the aforementioned 2002 / 0180687. The resultant microcapsules were separated by size and capsules having an average particle size of about 35 μm were used in the following experiments. The microcapsules were mixed into a slurry with a polyurethane binder and coated by a roll-to-roll process at a dry coating weight of 18 g m−2 on to the surface of a 7 mil (177 μm) poly(ethylene terephthalate) film carrying an indium tin oxide (ITO) layer on one surface, the microcapsules being deposited on the ITO-covered surface, substantially as described in Paragraphs [0075] and [0076] of the aforementioned 2002 / 0180687. The capsule-bearing film was then formed into a front plane laminate by laminating it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com