Movable barrier operator

a technology of operator and moving barrier, which is applied in the direction of electric programme control, dynamo-electric converter control, instruments, etc., can solve the problems of high impulse force application, and achieve the effect of less momentum, smooth and quiet stop, and safer barrier operator movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

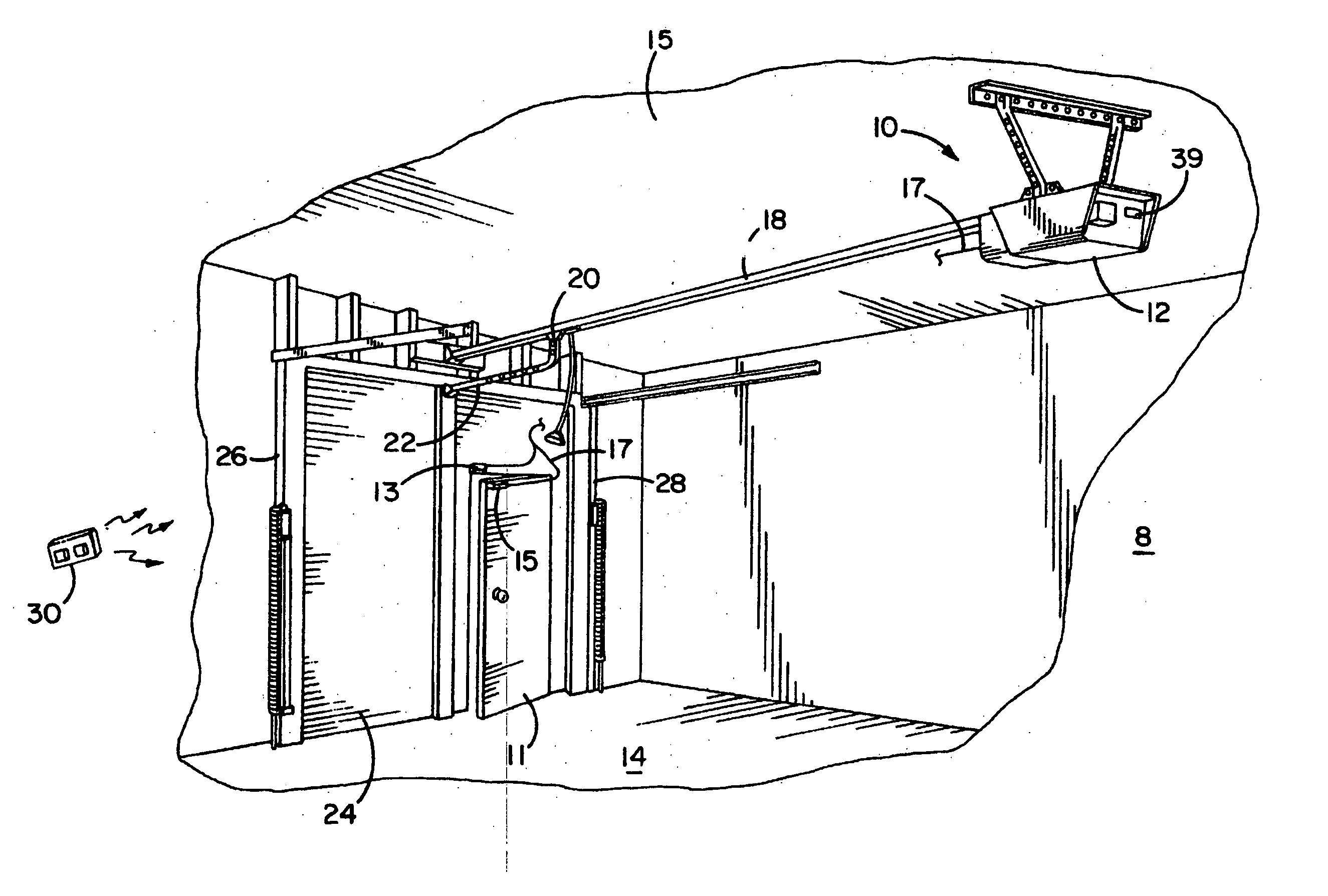

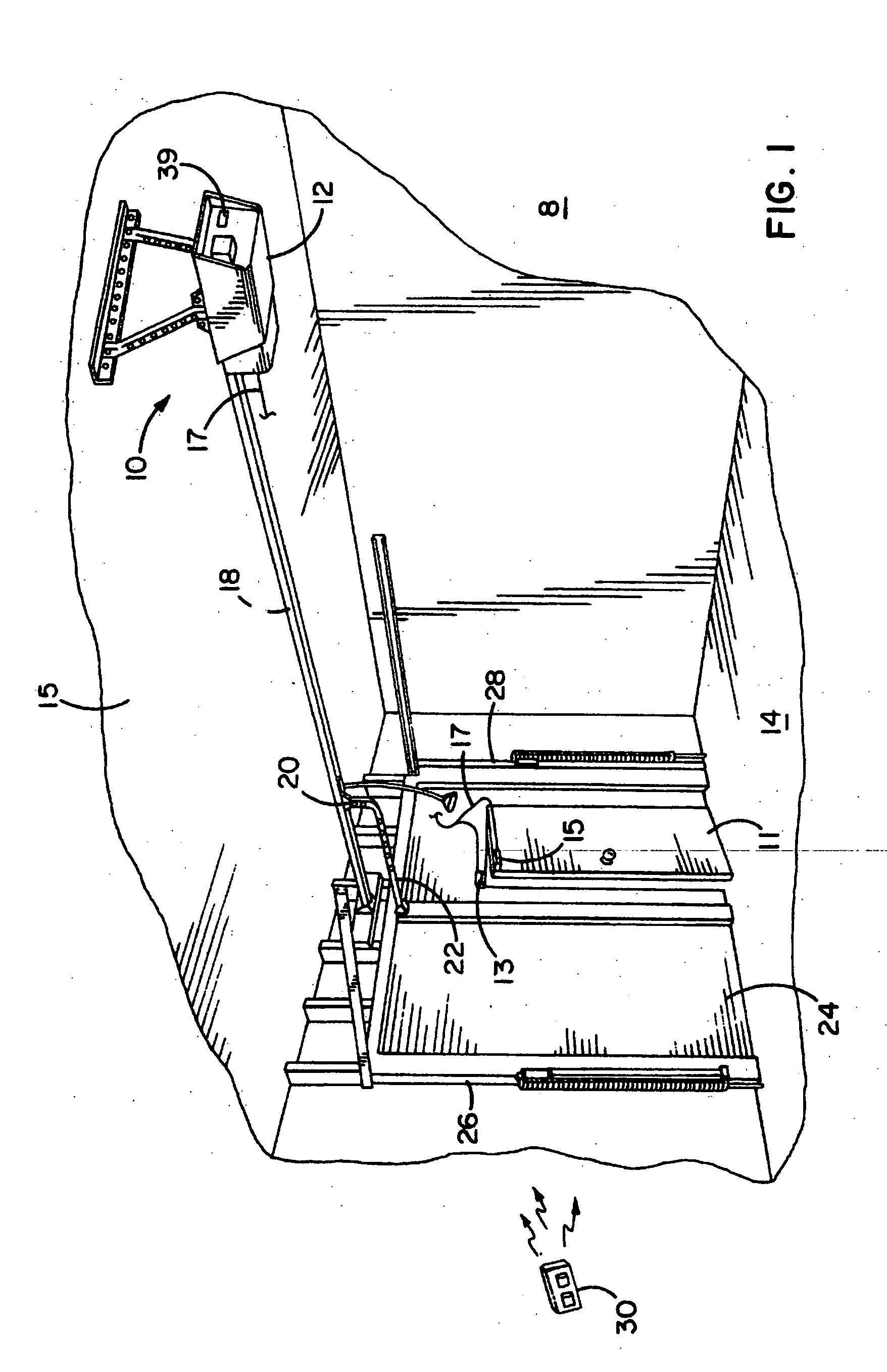

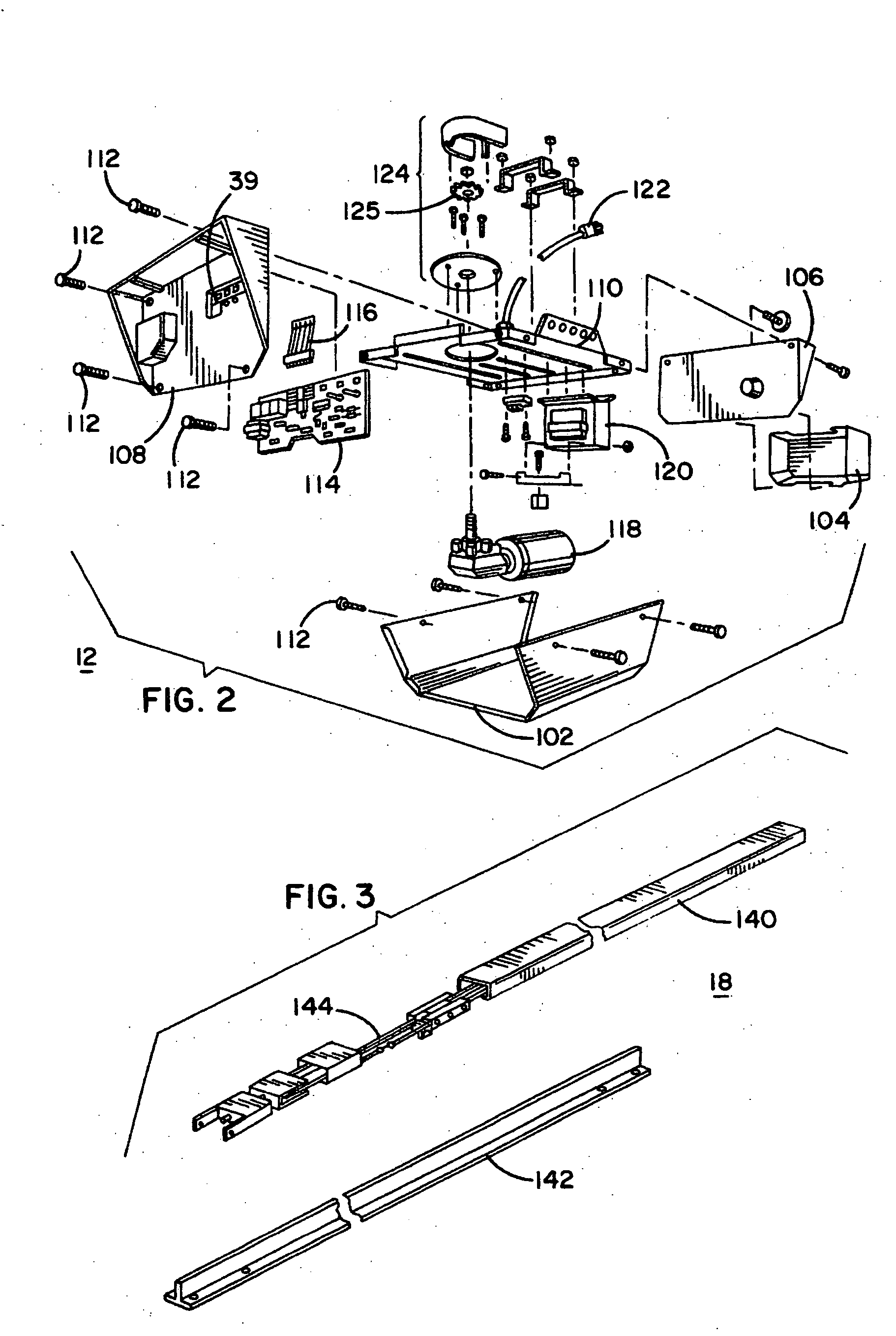

[0045] Referring now to the drawings and especially to FIG. 1, a movable barrier or garage door operator system is generally shown therein and referred to by numeral 8. The system 8 includes a movable barrier operator or garage door operator 10 having a head unit 12 mounted within a garage 14. More specifically, the head unit 12 is mounted to a ceiling 15 of the garage 14. The operator 10 includes a transmission 18 extending from the head unit 12 with a releasable trolley 20 attached. The releasable trolley 20 releasably connects an arm 22 extending to a single panel garage door 24 positioned for movement along a pair of door rails 26 and 28.

[0046] The system 8 includes a hand-held RF transmitter unit 30 adapted to send signals to an antenna 32 (see FIG. 4) positioned on the head unit 12 and coupled to a receiver within the head unit 12 as will appear hereinafter. A switch module 39 is mounted on the head unit 12. Switch module 39 includes switches for each of the commands availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com