Method of and device for coloring textiles

a textile and dyeing technology, applied in the field of continuous dyeing textiles, can solve the problem of not being able to use more efficiently for coloring, and achieve the effect of uniform coloring results and saving chemical quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

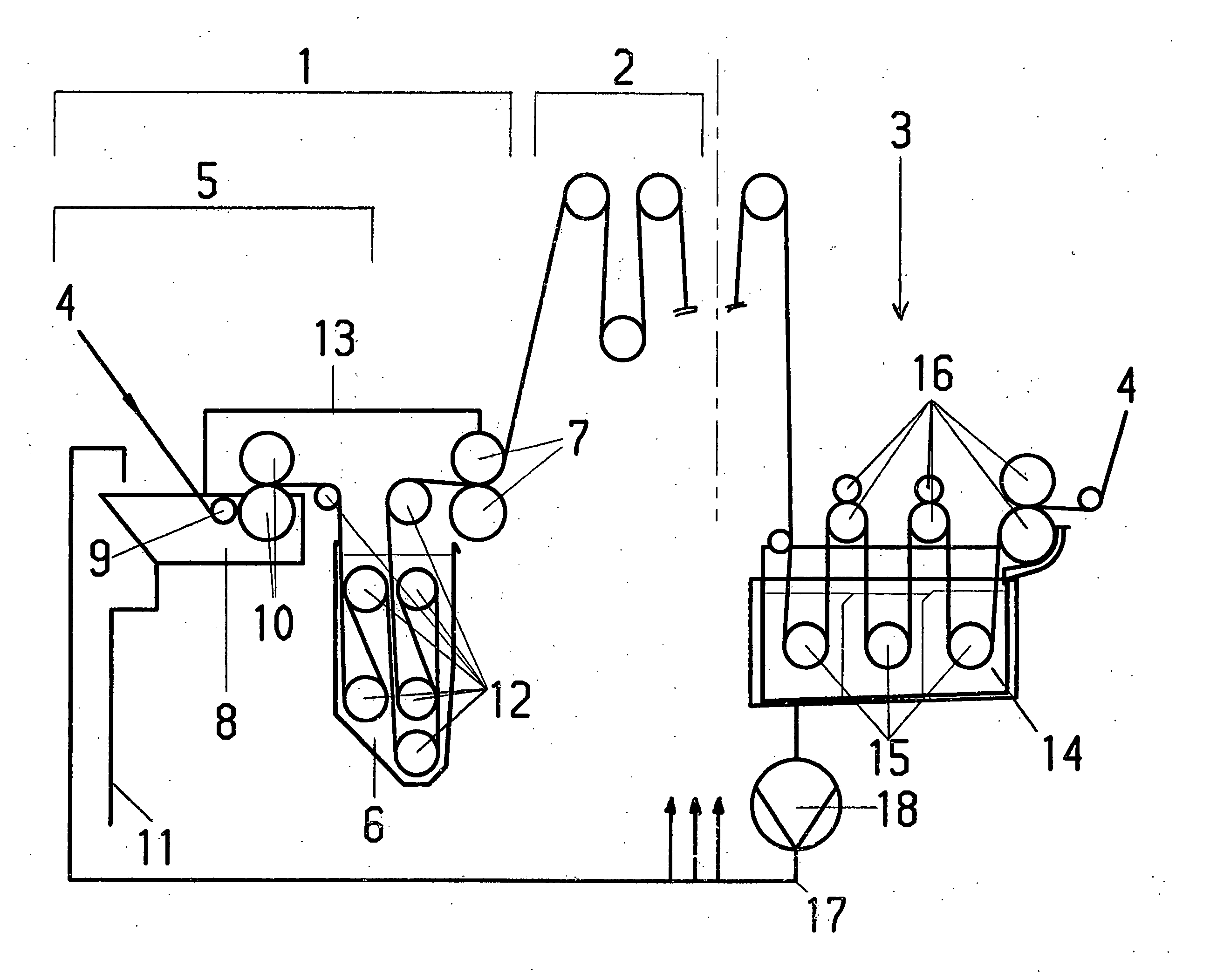

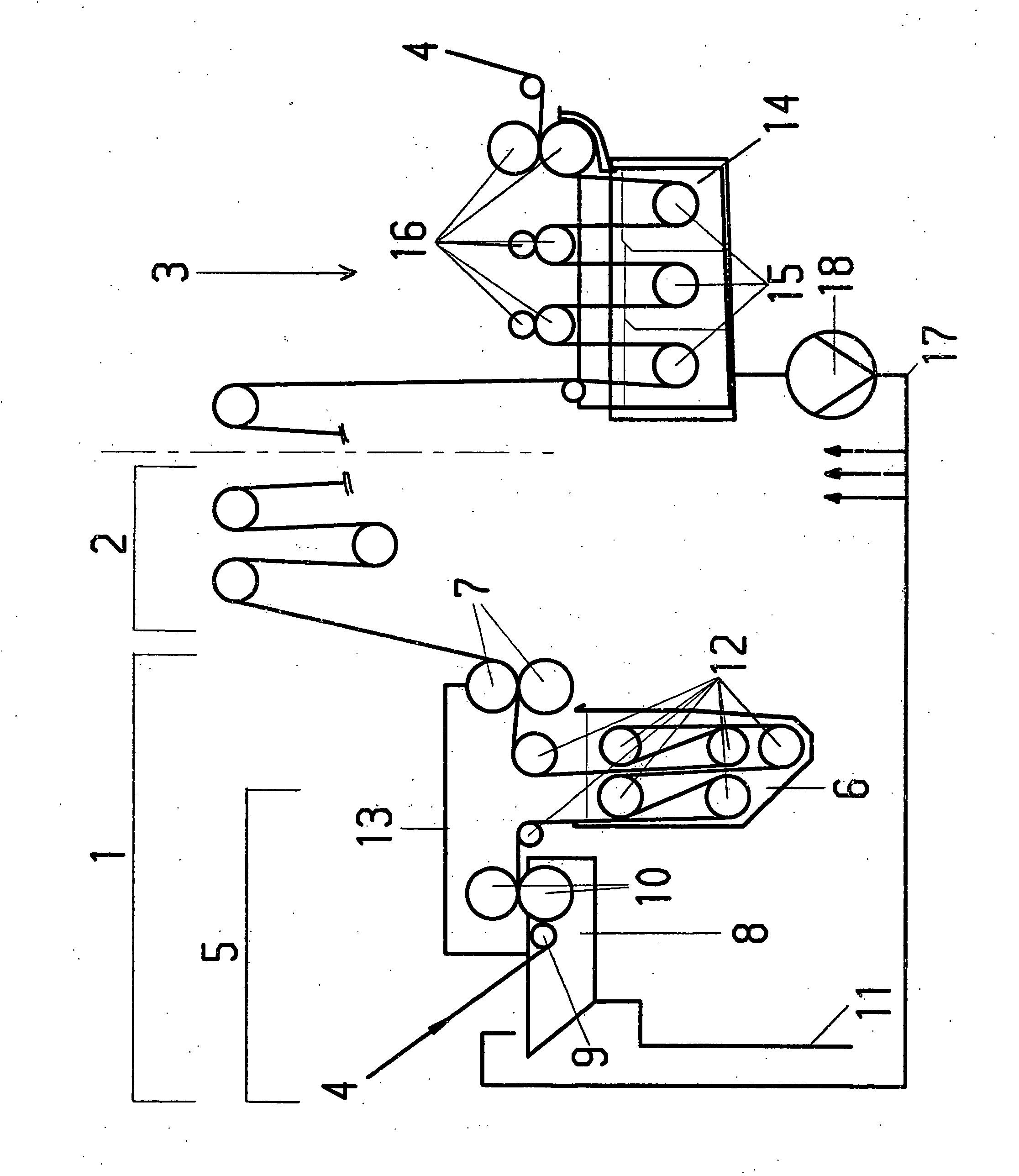

[0019] A device for coloring textiles in accordance with the present invention has a plurality of wetting stages 1. An oxidation line 2 and a washing device 3 follows each wetting stage 1. Furthermore, the device in accordance with the present invention has not shown means for supplying threads 4, in which the threads are wound for example in a bobbin by spools and supplied to coloring, and means for drying of the colored threads 4.

[0020] Each wetting stage 1 includes means for expelling oxygen 5 from the threads 4, a coloring substance trough 6, and a second squeezing mechanism 7.

[0021] The means for expelling 5 contain a trough 8 with at least one first deviating roll 9, and a first squeezing mechanism 10 arranged at an outlet of the threads 4 from the trough 8. An overflow conduit 11 is attached to the trough 8 and is connected with a drain.

[0022] At a short distance in the running direction of the threads 4 behind the first squeezing mechanism 10, the coloring trough 6 is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| squeezing pressure | aaaaa | aaaaa |

| affinity | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com