Method and apparatus for a reticle with purged pellicle-to-reticle gap

a technology of pellicle and reticle, applied in the field of photolithography systems, can solve the problem that the oxygen in the ambient atmosphere of the clean room cannot be purged, and achieve the effect of reducing or eliminating pellicle or pellicle distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] To more clearly delineate the present invention, an effort is made throughout the specification to adhere to the following term definitions as consistently as possible.

[0033]“Ambient air” means an oxygen-containing atmosphere, such as normal atmospheric air. For instance, “ambient air” may mean air in an oxygen-containing clean room atmosphere or environment.

[0034]“Purge gas” means a gas that does not contain oxygen, or some other undesired gas, and is used to fill a purged air gap or space.

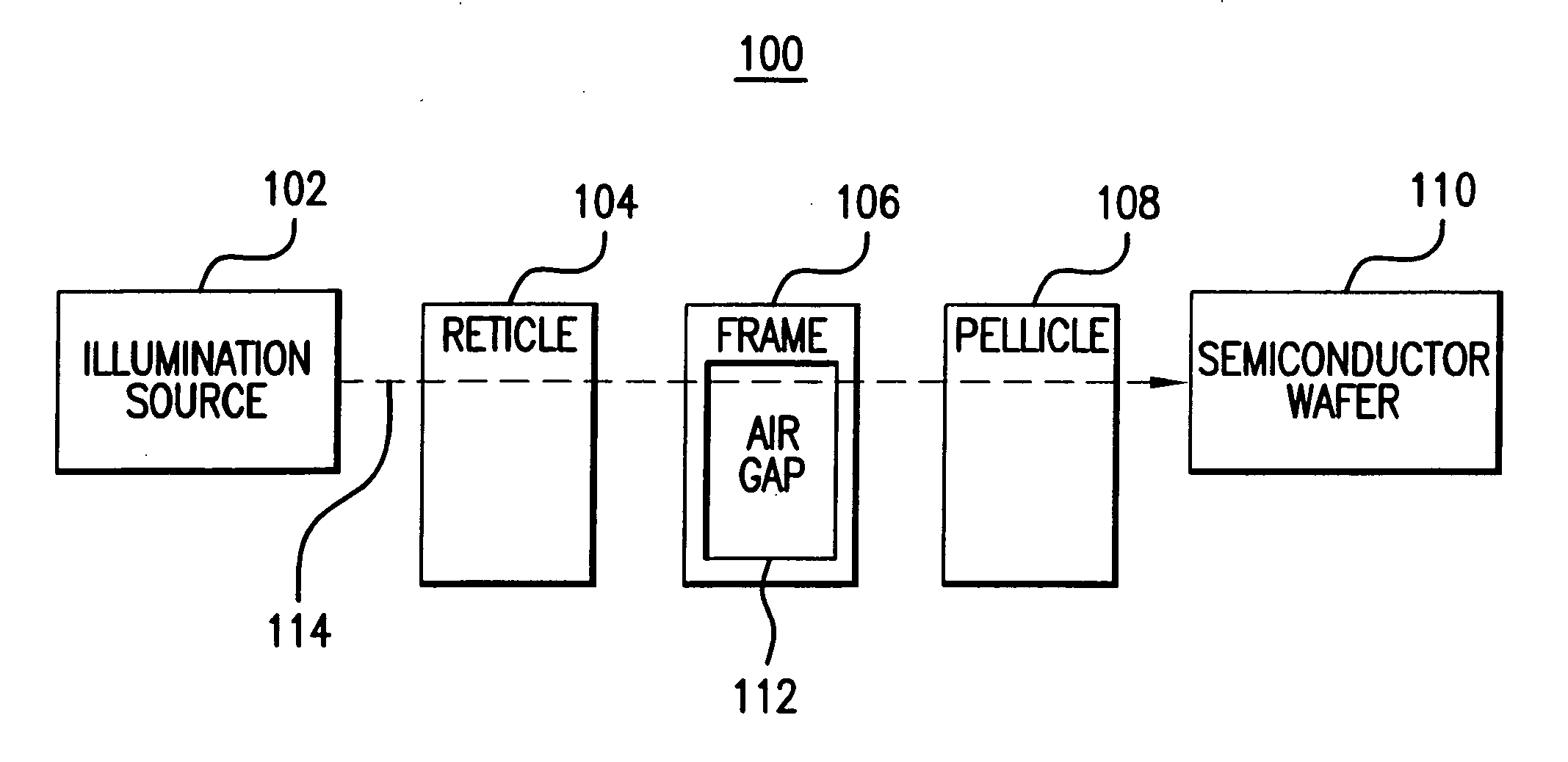

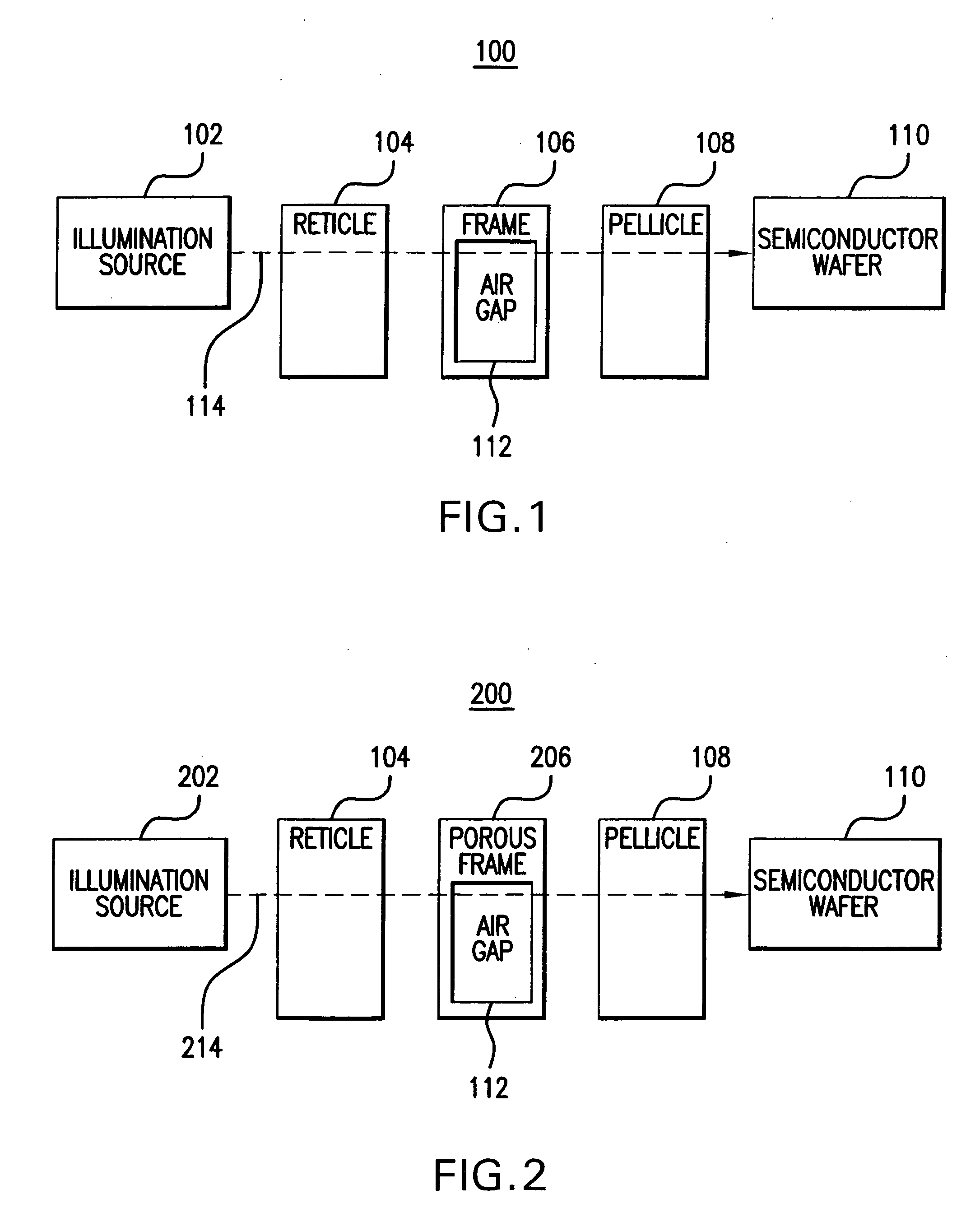

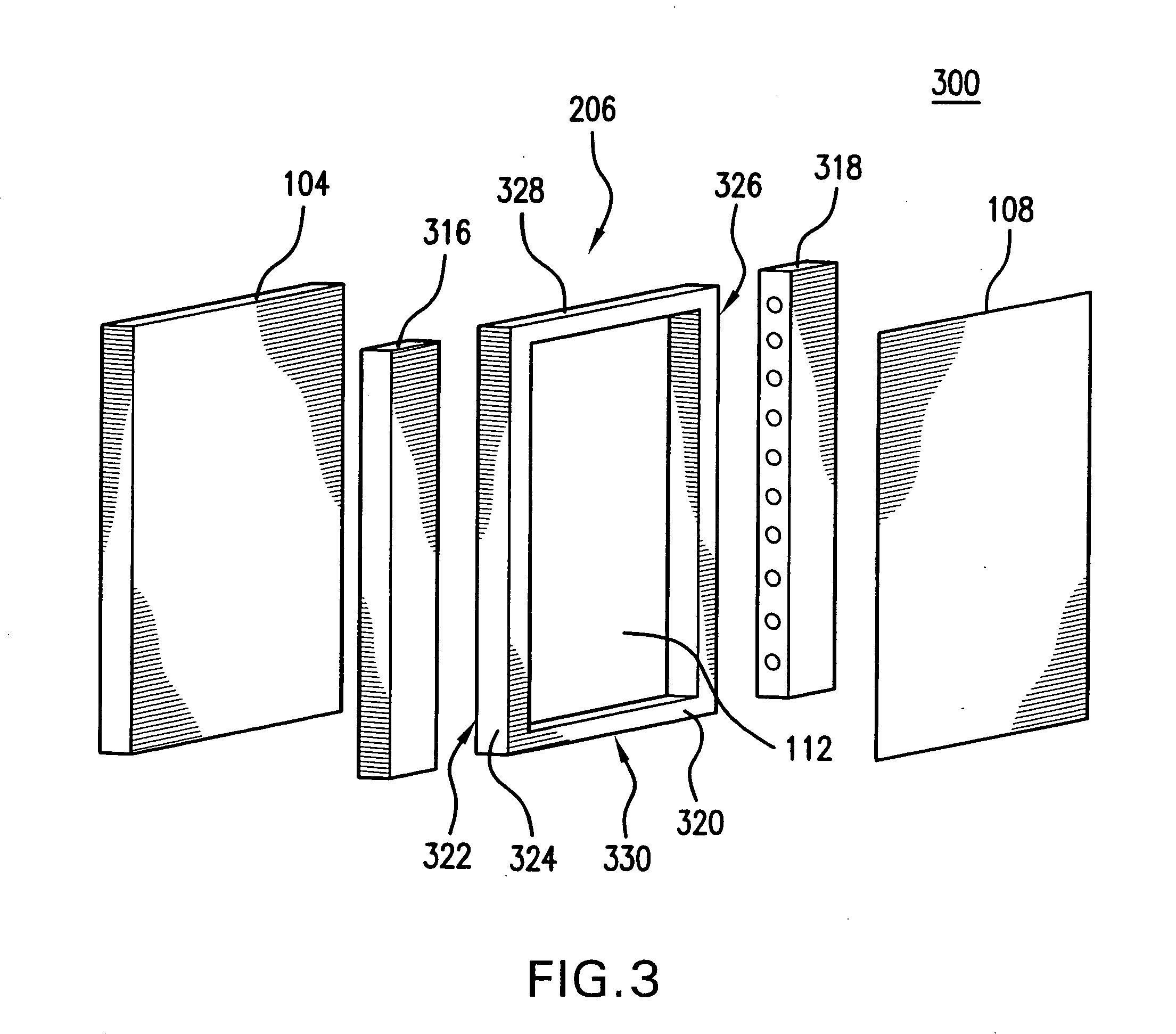

[0035]FIG. 1 illustrates a relevant portion of a conventional photolithography system 100. Conventional photolithography system 100 is located in an ambient air or gas environment. Some portions of a conventional photolithography system may not be shown in FIG. 1 for purposes of brevity, such as source optics, projection optics, etc.

[0036] Conventional photolithography system 100 comprises an illumination source 102, a reticle 104, a frame 106, a pellicle 108, and a semiconductor wafer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| light wavelengths | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com