Low energy method of pyrolysis of hydrocarbon materials such as rubber

a hydrocarbon material and low energy technology, applied in the direction of catalytic material combustion, lighting and heating apparatus, combustion types, etc., can solve the problems of increasing the temperature required to promote thermal cracking, increasing the risk of cleavage, and reducing the energy. , to achieve the effect of improving the solid reaction product, improving the energy, and rapid ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

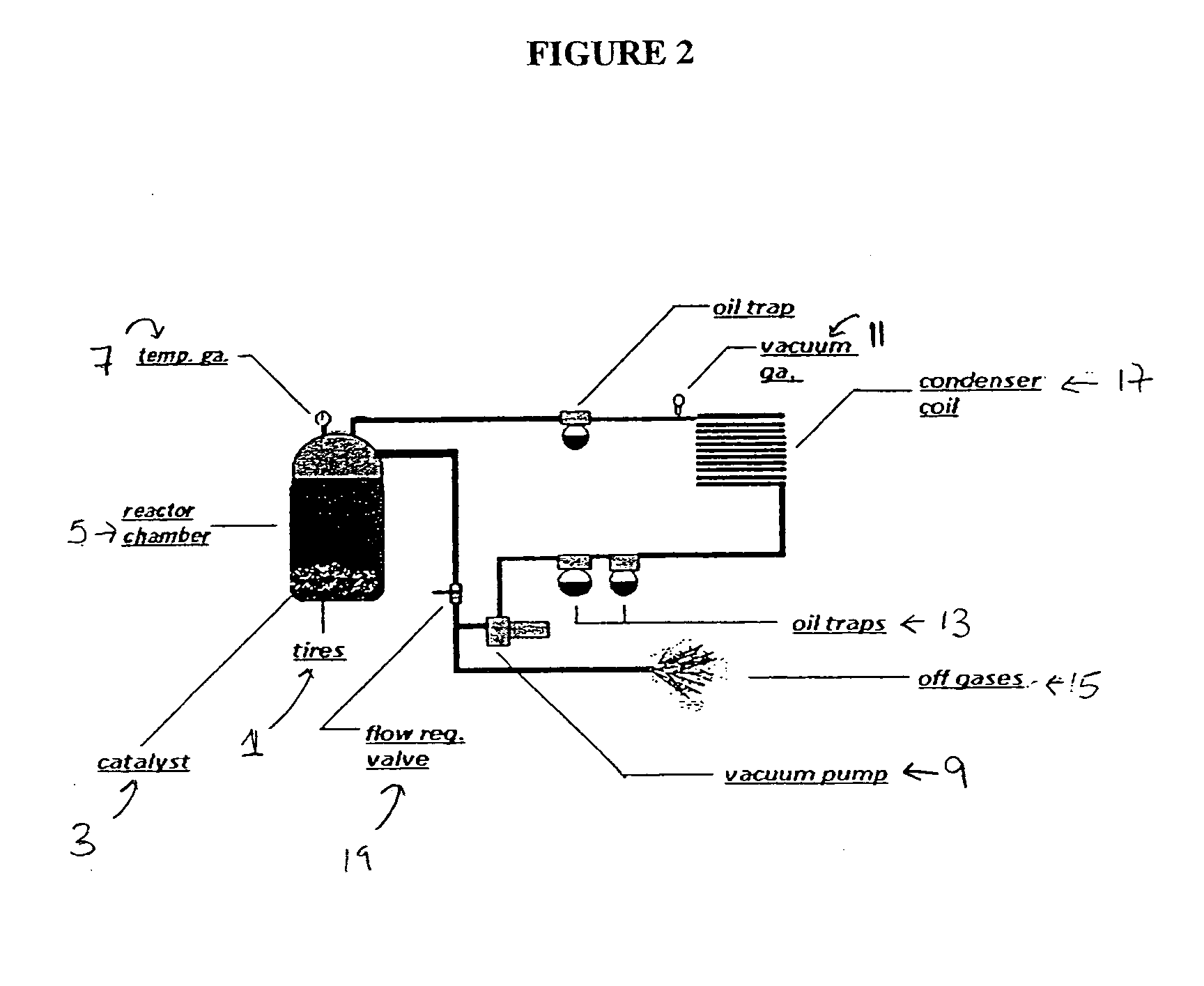

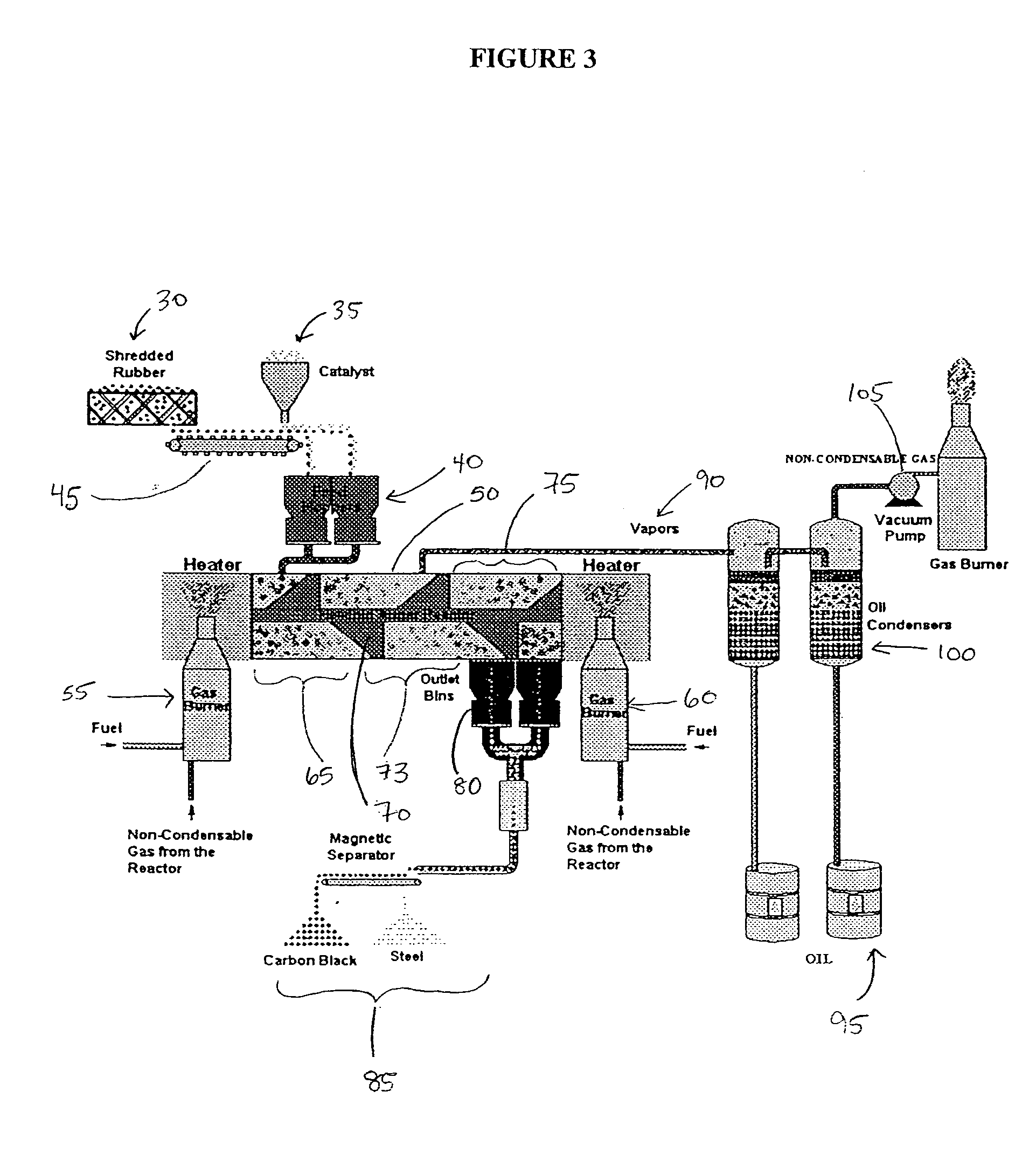

[0029] The present invention provides a low energy method of pyrolysis of hydrocarbon material comprising providing hydrocarbon material; loading the hydrocarbon material into a reaction chamber; adding a catalyst to the reaction chamber; and heating the reaction chamber. This method occurs under vacuum conditions and yields reaction products comprising a carbonaceous solid residue, a liquid hydrocarbon product and a combustible gas.

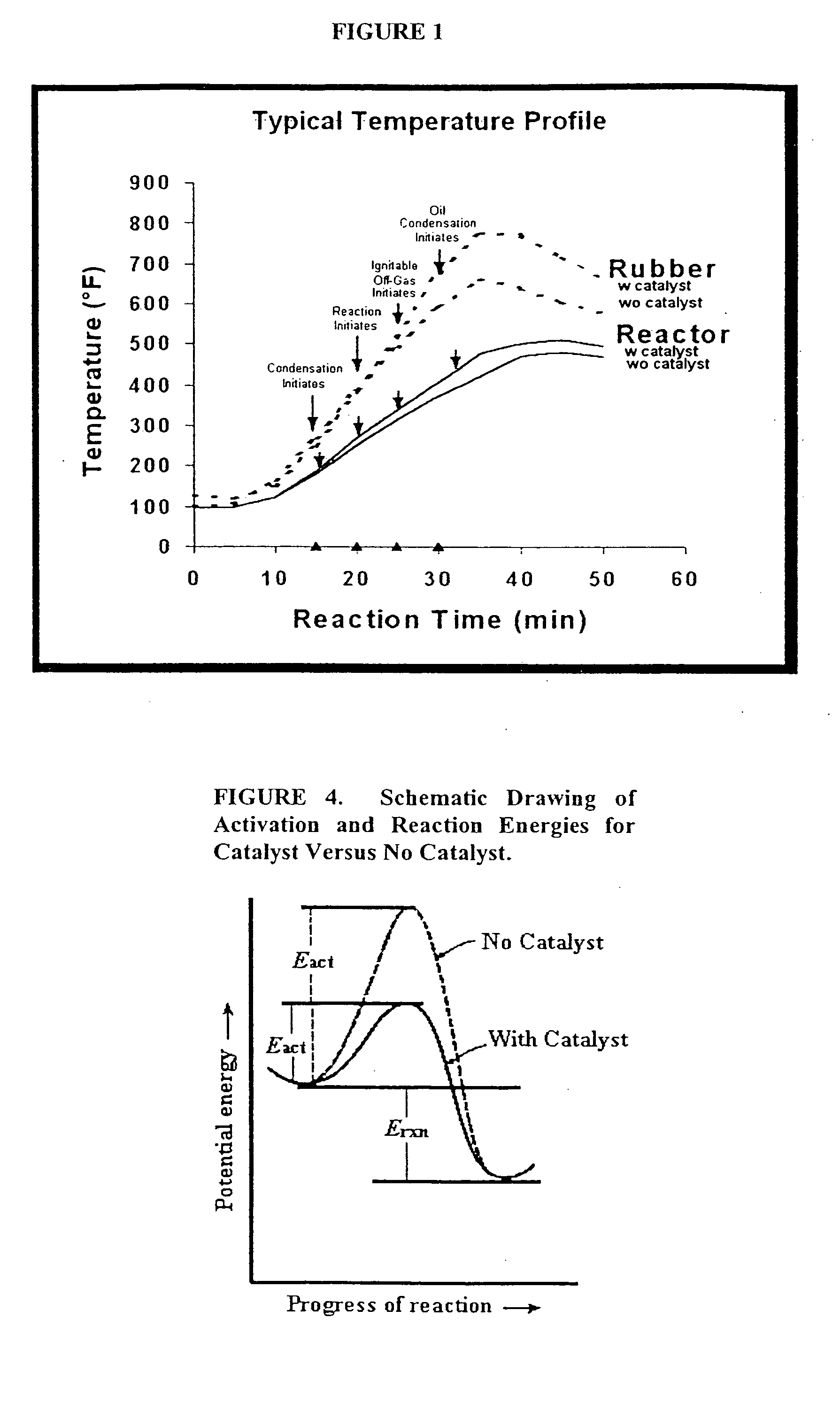

[0030] The catalyst in the present invention is a clay catalyst which allows the process to proceed at a more rapid rate with lower energy input than other prior art processes. In addition, use of the clay catalyst in combination with vacuum conditions results in a solid residue of higher quality than that achievable with other methods. The process is designed to optimize energy requirements by 1) utilizing a catalyst to lower the activation energy; 2) recycling combustible gas generated by the process and 3) utilizing energy generated by bond cleavage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com