Method for edge sealing barrier films

a technology of barrier films and thin films, applied in the direction of cell components, instruments, semiconductor/solid-state device details, etc., can solve the problems of reducing the area of the substrate which is usable, compromising the encapsulation, and finite lateral diffusion rate of moisture and oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

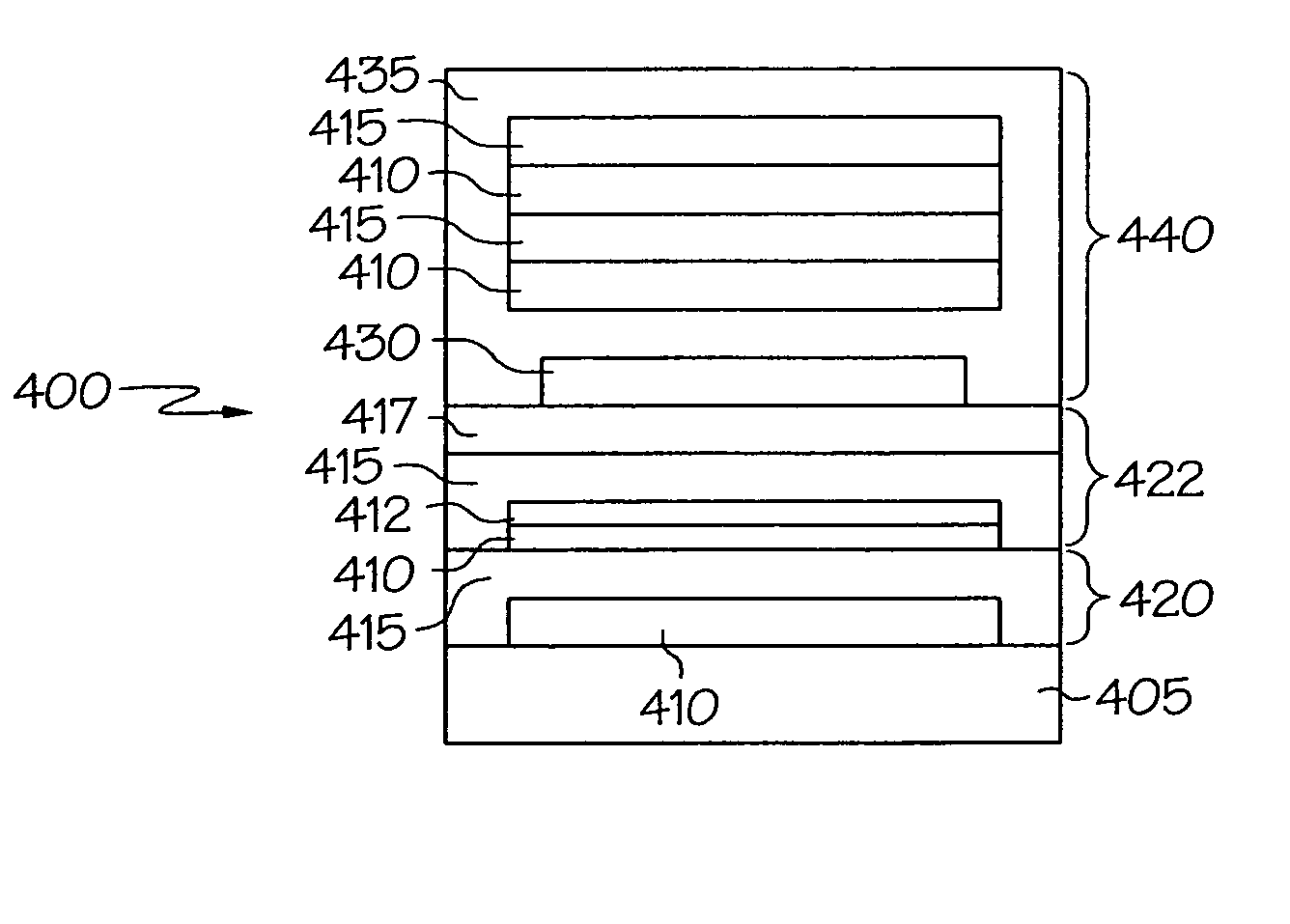

[0024]FIG. 2 shows one embodiment of an edge-sealed, barrier composite 200. The composite 200 includes a substrate 205. The substrate can be any suitable substrate, and can be either rigid or flexible. Suitable substrates include, but are not limited to: polymers, for example, polyethylene terephthalate (PET), polyethylene naphthalate (PEN), or high temperature polymers, such as polyether sulfone (PES), polyimides, or Transphan™ (a high glass transition temperature cyclic olefin polymer available from Lofo High Tech Film, GMBH of Weil am Rhein, Germany); metals and metal foils; paper; fabric; glass, including thin, flexible, glass sheet (for example, flexible glass sheet available from Coming Inc. under the glass code 0211. This particular thin, flexible glass sheet has a thickness of less than 0.6 mm and will bend at a radium of about 8 inches.); ceramics; semiconductors; silicon; and combinations thereof.

[0025]FIG. 2 shows three initial barrier stacks 220 adjacent to the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com