Method of manufacture of a chromogenic panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

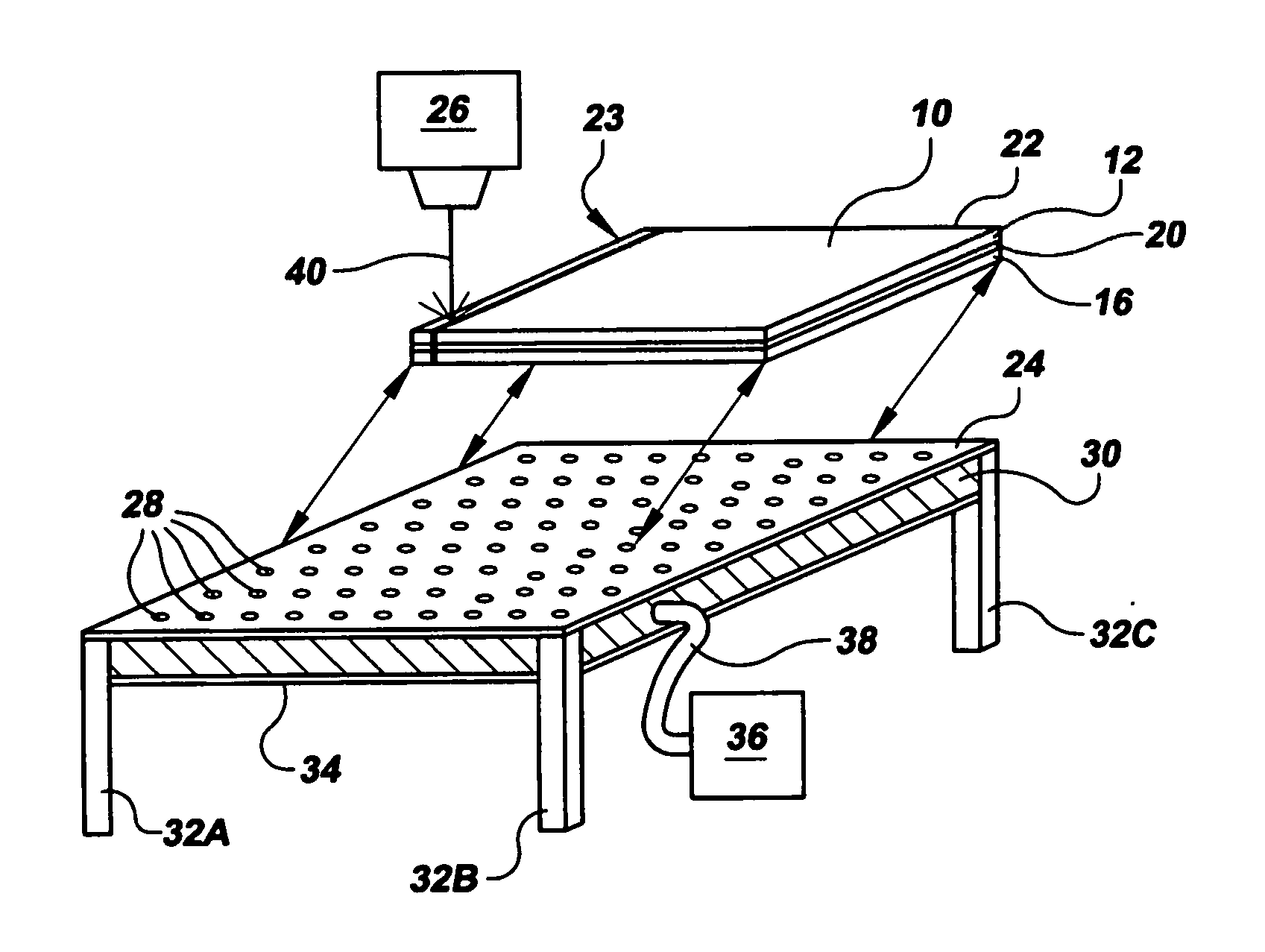

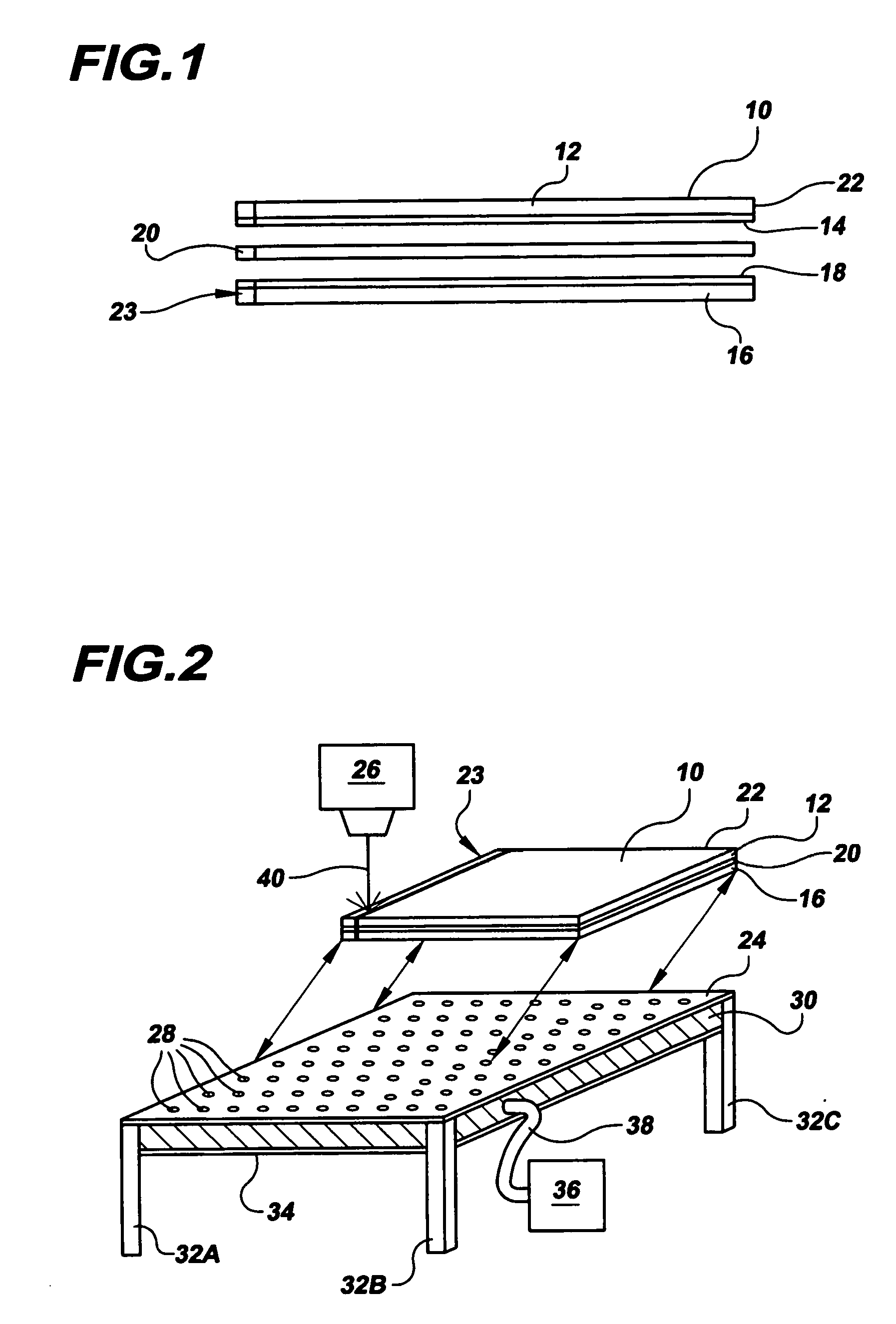

[0023] The invention is a method of manufacturing a chromogenic panel 10 that provides for varying optical characteristics in response to varying energy signals. The method comprises the steps of first securing at least one chromogenic matrix 20 between a first electrically conductive surface 14 of a first substrate 12 and a second electrically conductive 16 surface of a second substrate 18 to form a chromogenic film 23 as best shown in FIG. 1. Next, the chromogenic film 23 is secured to an especially flat cutting surface 24. It has been determined by the inventors herein that use of a laser 26 to cut the chromogenic panel 10 requires that the surface of the panel 10 being cut must be extremely flat. Therefore, a flat cutting surface 24 for purposes herein is defined to have no variations within a plane of the surface 24 that are greater than plus or minus one-fiftieth of an inch, or preferably, plus or minus one-hundredth of an inch.

[0024] The flat cutting surface 24 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com