Decorative material and decorative sheet

a technology of decorative sheets and decorative sheets, applied in the direction of instruments, synthetic resin layered products, transportation and packaging, etc., can solve the problems of grain depression, doctor streaks, and insufficient scraping of the ink of this part, and achieve the effect of proper flow ability, easy and continuous production, and viscosity and thixotropic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) First Embodiment

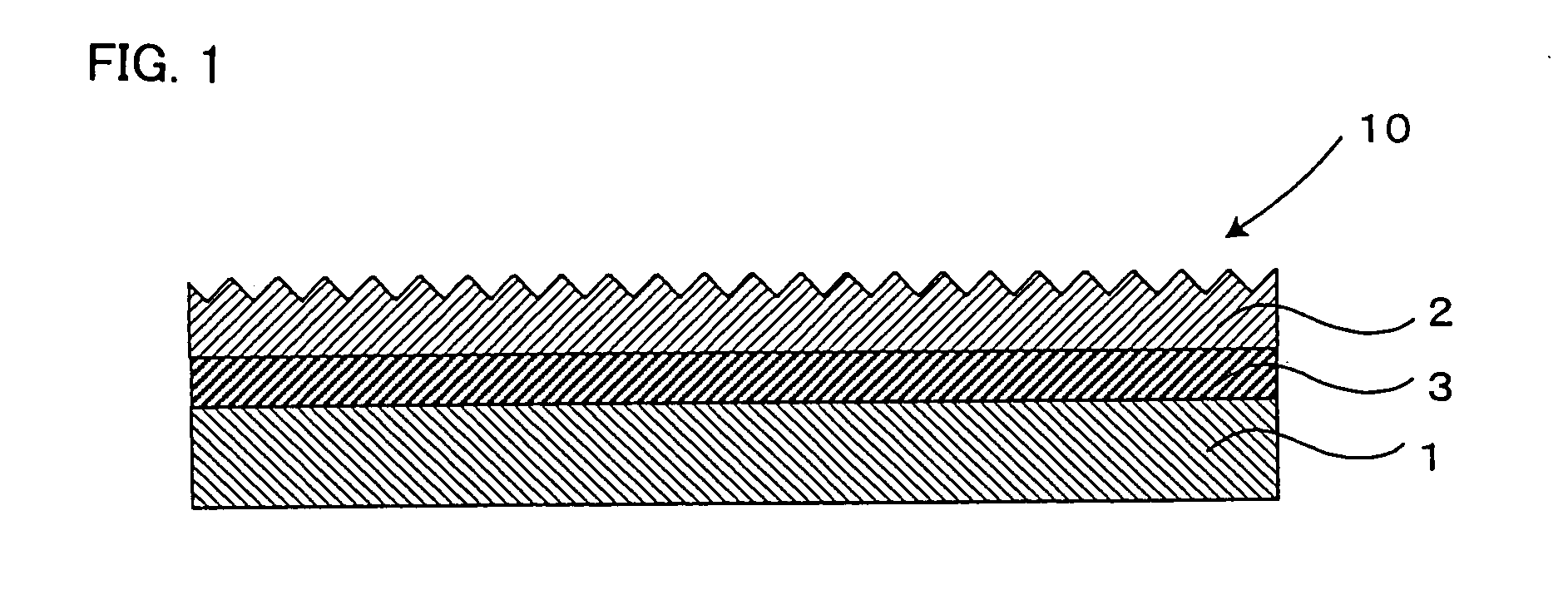

[0052] At first, the first embodiment of the decorative material of the present invention will be explained. For example as shown in FIG. 1, the first embodiment of a decorative material of the present invention comprises at least: a base material 1; and a luster adjusting resin layer 2, formed thereon, which is formed of a cross-linked cured material of an ionizing radiation curing resin containing delustering silica, and for the delustering silica contained in the luster adjusting resin layer 2, the delustering silica, whose surface is treated with fatty acid based wax, is used.

[0053] Hereinafter, the respective components of the decorative material of this embodiment will be explained.

[Luster Adjusting Resin Layer]

[0054] At first, the luster adjusting resin layer 2 is a layer for providing surface physical properties such as abrasion resistance to the decorative material surface and adjusting the surface luster of the decorative material to lower the luster...

second embodiment

(2) Second Embodiment

[0094] Next, the second embodiment of a decorative material of the present invention will be explained. As shown in FIG. 1, the second embodiment of a decorative material of the present invention comprises at least a base material 1 and a luster adjusting resin layer 2, formed thereon, which is formed of a cross-linked cured material of an ionizing radiation curing resin containing delustering silica, and the luster adjusting resin layer 2 further contains either of both of magnesium hydroxide and magnesium carbonate, in addition to the delustering silica.

[0095] Hereinafter, the respective components of the decorative material of this embodiment will be explained.

[Luster Adjusting Resin Layer]

[0096] At first, the luster adjusting resin layer 2 is a layer for providing surface physical properties such as abrasion resistance to the decorative material surface and for adjusting the surface luster of the decorative material to lower the luster or to deluster the ...

example 1

[0183] First, by using a coloring ink using a nitrocellulose based resin as a binder resin, a decorative layer, which is also used as a screening layer, was formed on a base material, formed of a resin impregnated paper of basic weight of 50 g m2, in a solid gray pattern for the entire surface by a gravure printing.

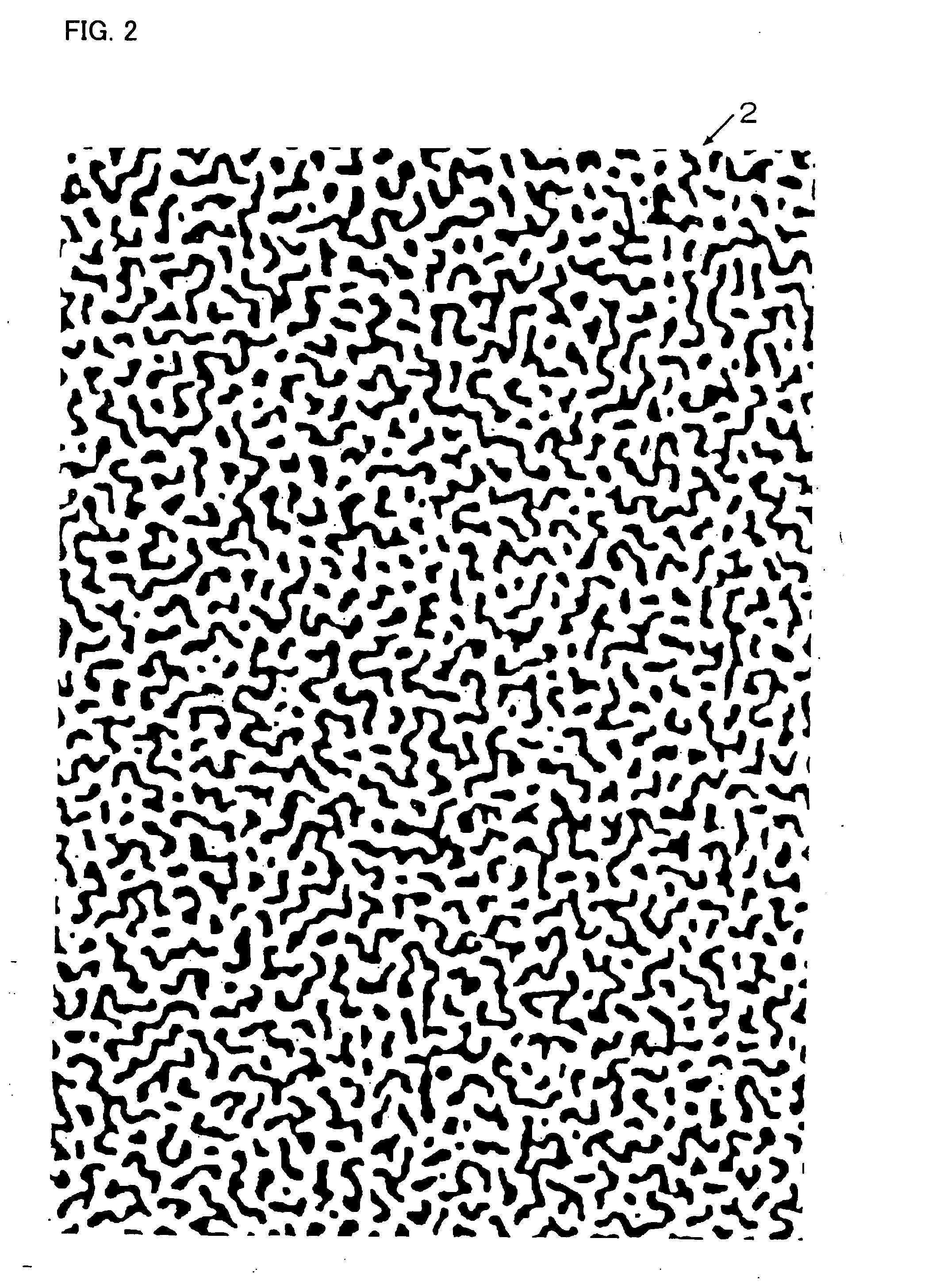

[0184] Next, by using a non-solvent ink formed of the below mentioned ionizing radiation curing resin composition, a predetermined decorative material was obtained as follows. After the gravure printing (relief printing) using a ceramic doctor and a gravure plate with a pattern as shown in a plane view in FIG. 2 (magnification), a luster adjusting resin layer, formed with a cross-link curing resin obtained by curing the ink with ionizing radiation, was provided on the decorative layer forming side. The luster of the decorative material was delustered by the luster adjusting resin layer, and a convex-concave surface design was imparted by the layer. Types of the luster ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com