Flame resistant fabrics with improved aesthetics and comfort, and method of making same

a technology of aesthetics and comfort, which is applied in the field offlame resistant fabrics with improved aesthetics and comfort, and the method of making same, can solve the problems of extreme deficiency of aesthetic characteristics such as wearer comfort, harsh handling, hot and uncomfortable wearers, etc., and achieve the effect of improving wearer comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

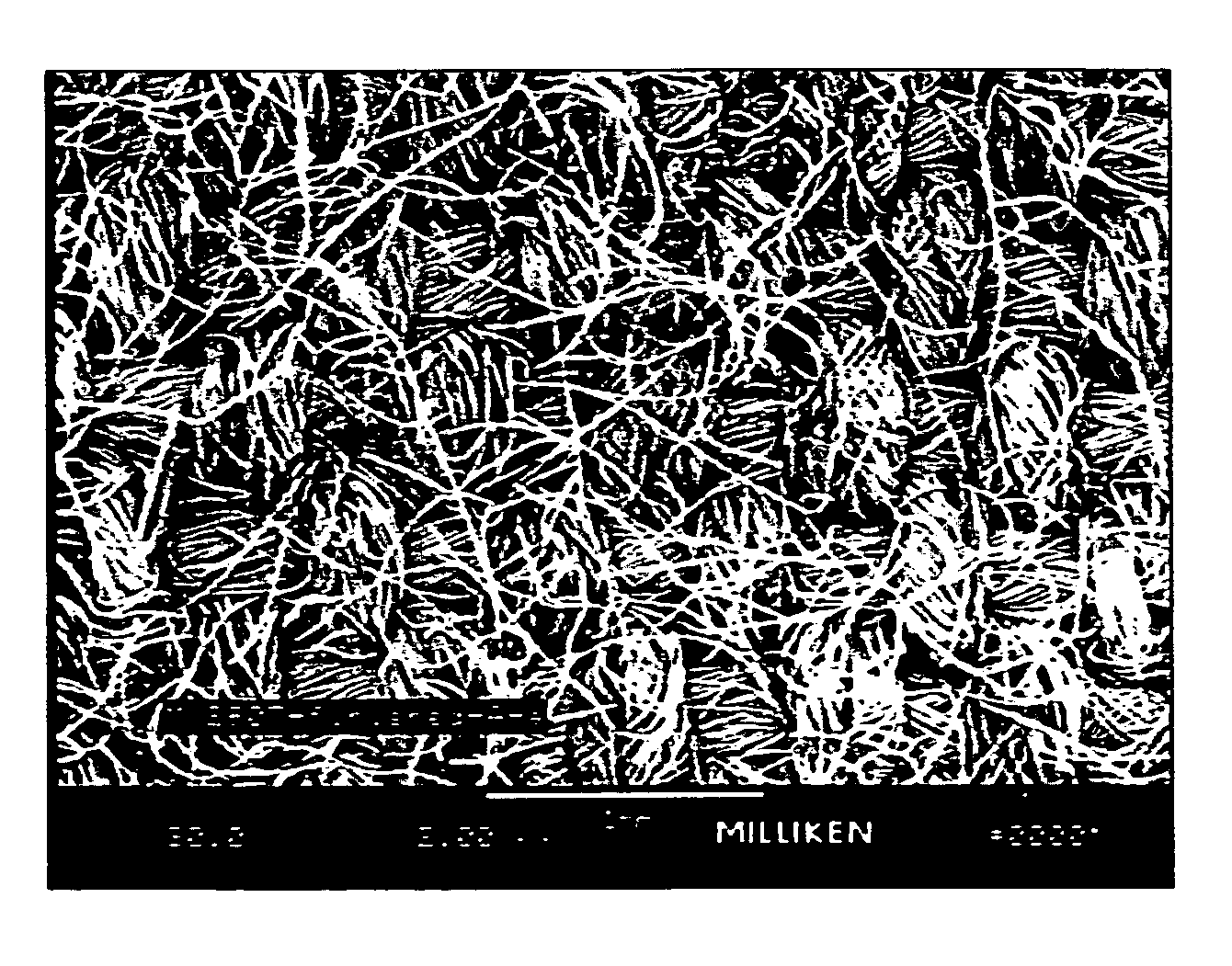

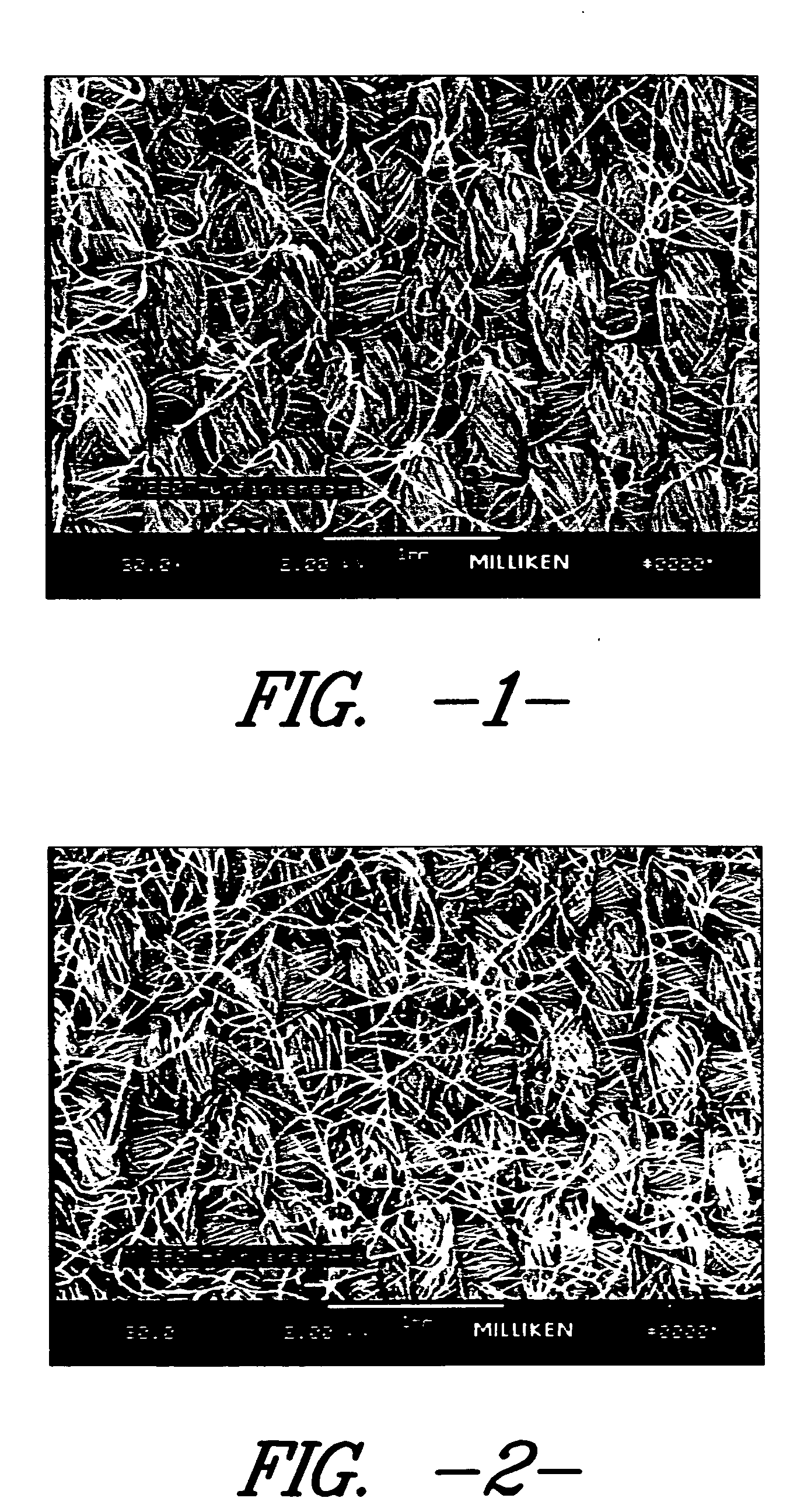

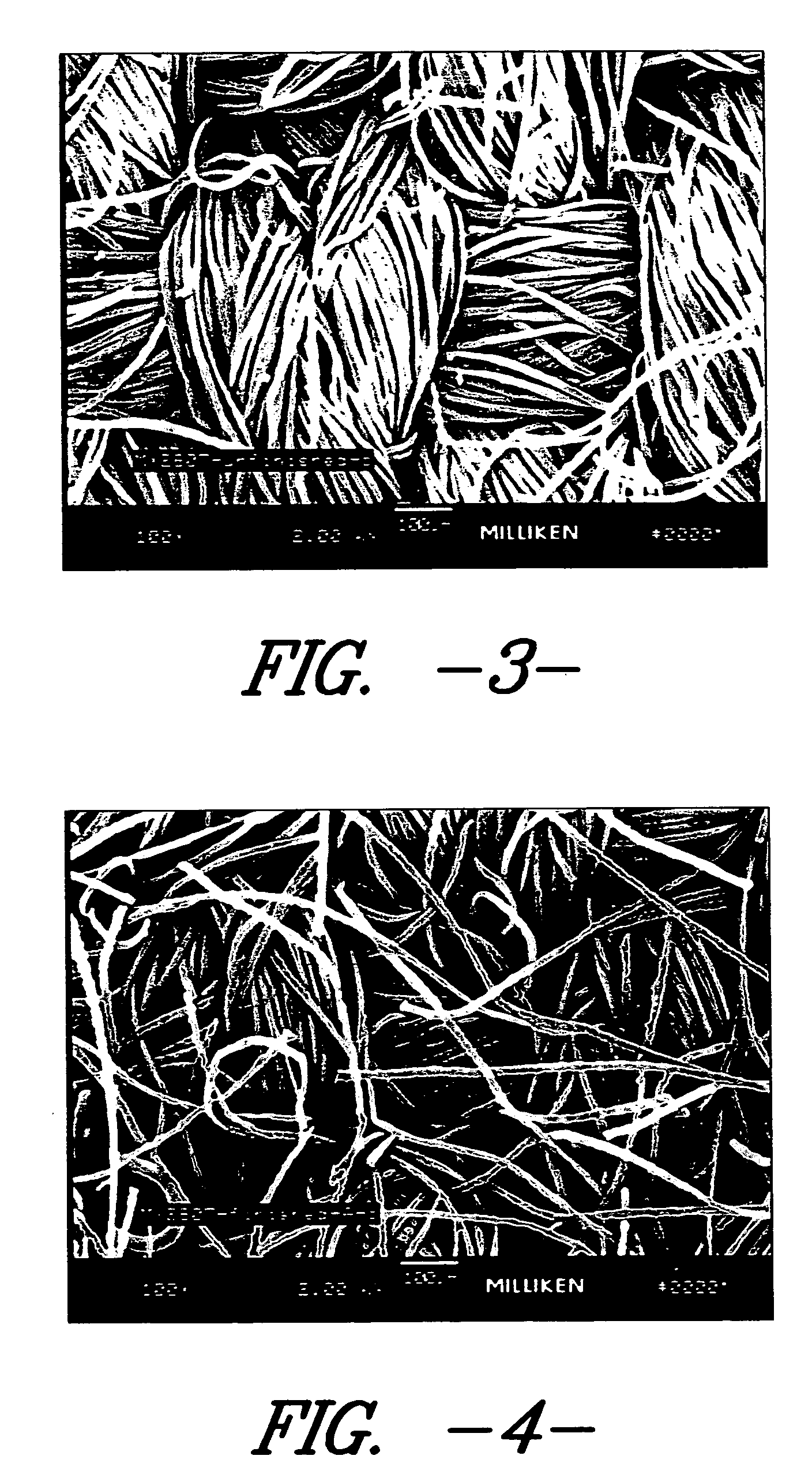

Image

Examples

examples

[0035] Example A—A fabric was woven from 30 / 2 100% Nomex IIIA® air-jet spun yarns (95% Aramid, 3% Kevlar®, and 2% Nylon P-140 (from DuPont) with a twist multiple of 14 of the variety available from Pharr Yarns of McAdenville, N.C. in a 1×1 plain weave construction. The fabric was jet dyed in a conventional manner using cationic dyes of the variety conventionally recommended for the dyeing of the Nomex, and acid dyes of the variety commonly used to dye nylon (both of which will be readily appreciated by those of ordinary skill in the art. Dyeing was performed at approximately 266° F. for one hour. The fabric was then passed through a pad containing 1-½% Lurotex A-25 ethoxylated polyamide (distributed by BASF of Mount Olive, N.J.) and 1-½% Lubril QCX high molecular weight ethoxylated polyester manufactured by Tennessee Eastman (to facilitate stain release and wicking). The fabric was then dried in a conventional manner on a tenter frame at about 410° F. at a speed of approximately 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com