Substrate processing apparatus, substrate processing method, and program for implementing the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

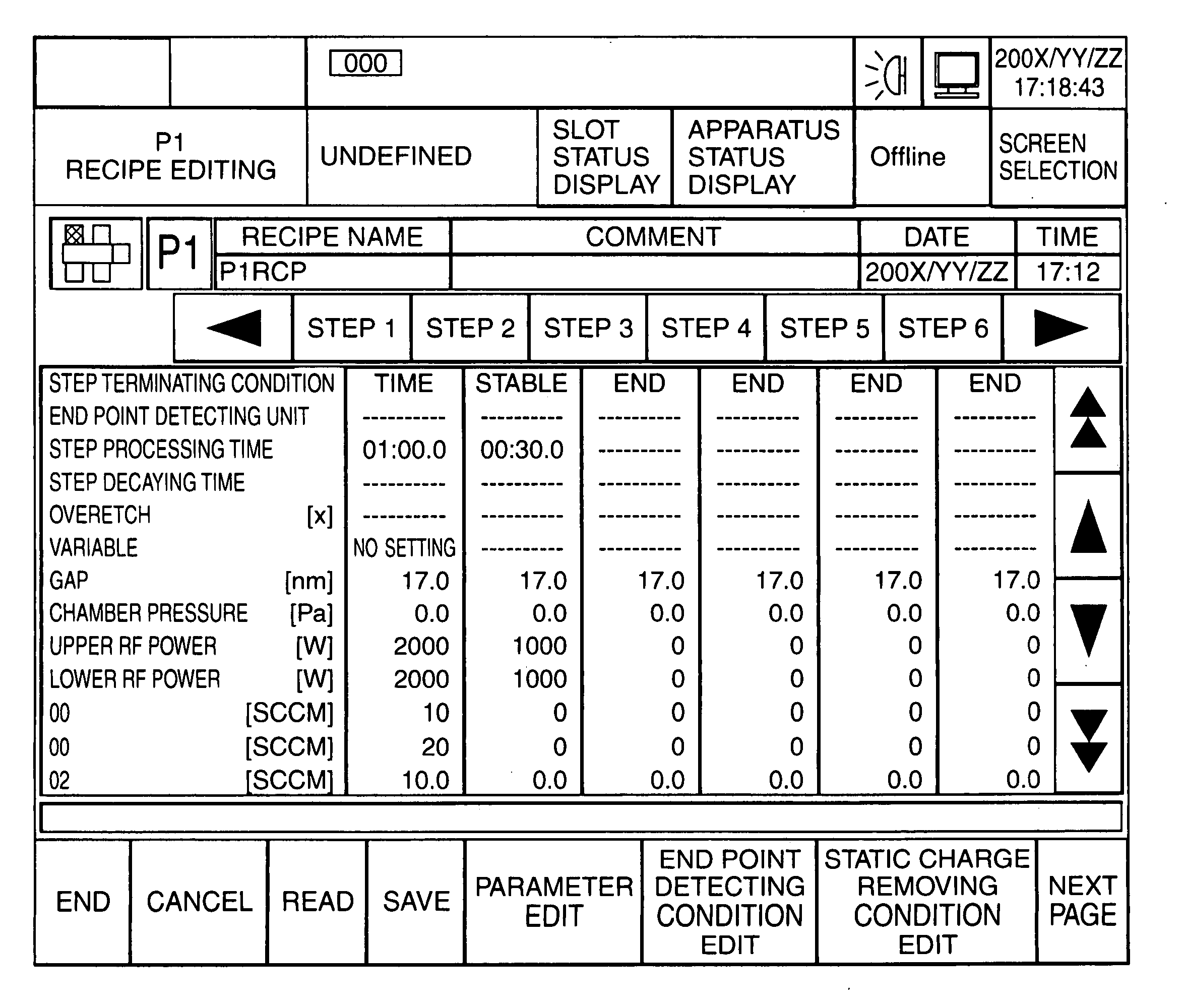

Image

Examples

Embodiment Construction

[0063] The present invention will now be described in detail with reference to the drawings showing a preferred embodiment thereof.

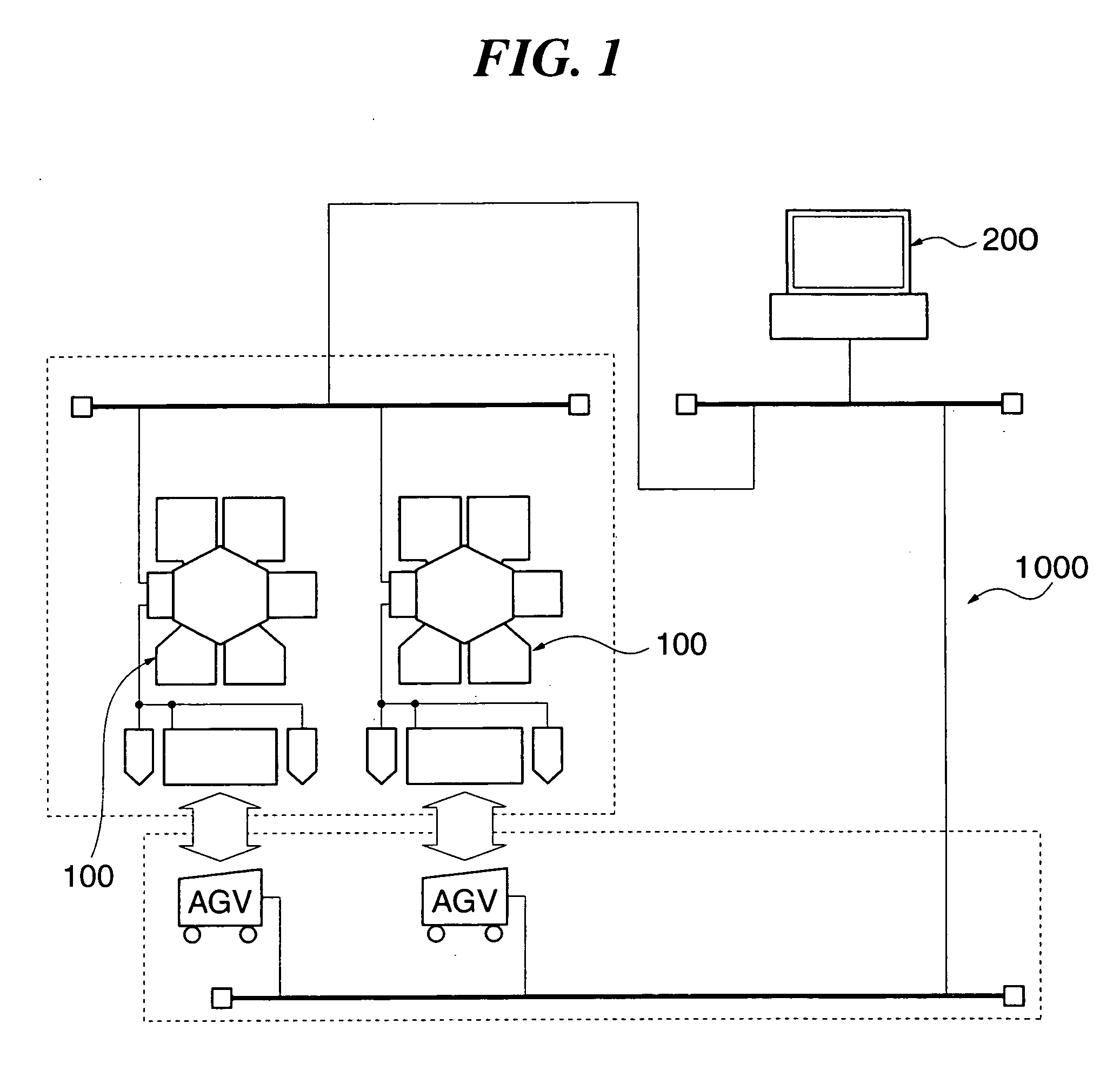

[0064]FIG. 1 is a block diagram schematically showing the arrangement of a substrate processing system including a substrate processing apparatus according to an embodiment of the present invention.

[0065] The substrate processing system 1000 shown in FIG. 1 is comprised of at least one etching apparatus 100 as a substrate processing apparatus, an auto guided vehicle (AGV) for conveying a cassette, referred to hereinafter, containing semiconductor substrates (hereinafter simply referred to as “substrates”) to the etching apparatus 100, and a host computer 200 connected to the AGV and the etching apparatus 100 via a network.

[0066] A transfer recipe, a product processing recipe, and a dummy processing recipe, all of which will be described in detail hereinafter, are registered in advance as programs in the host computer 200, and based on unattended contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar density | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com