Fracture-inducing lid for isolation pocket form

a technology of fracture-inducing lids and isolation pockets, which is applied in the direction of struts, constructions, building components, etc., can solve the problems of difficult removal of temporary wooden forms, difficult to remove temporary wooden forms, and less useful floor surfaces for new “tilt-up” construction techniques, etc., to achieve save considerable time and labor, and the effect of convenient and clean breakou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

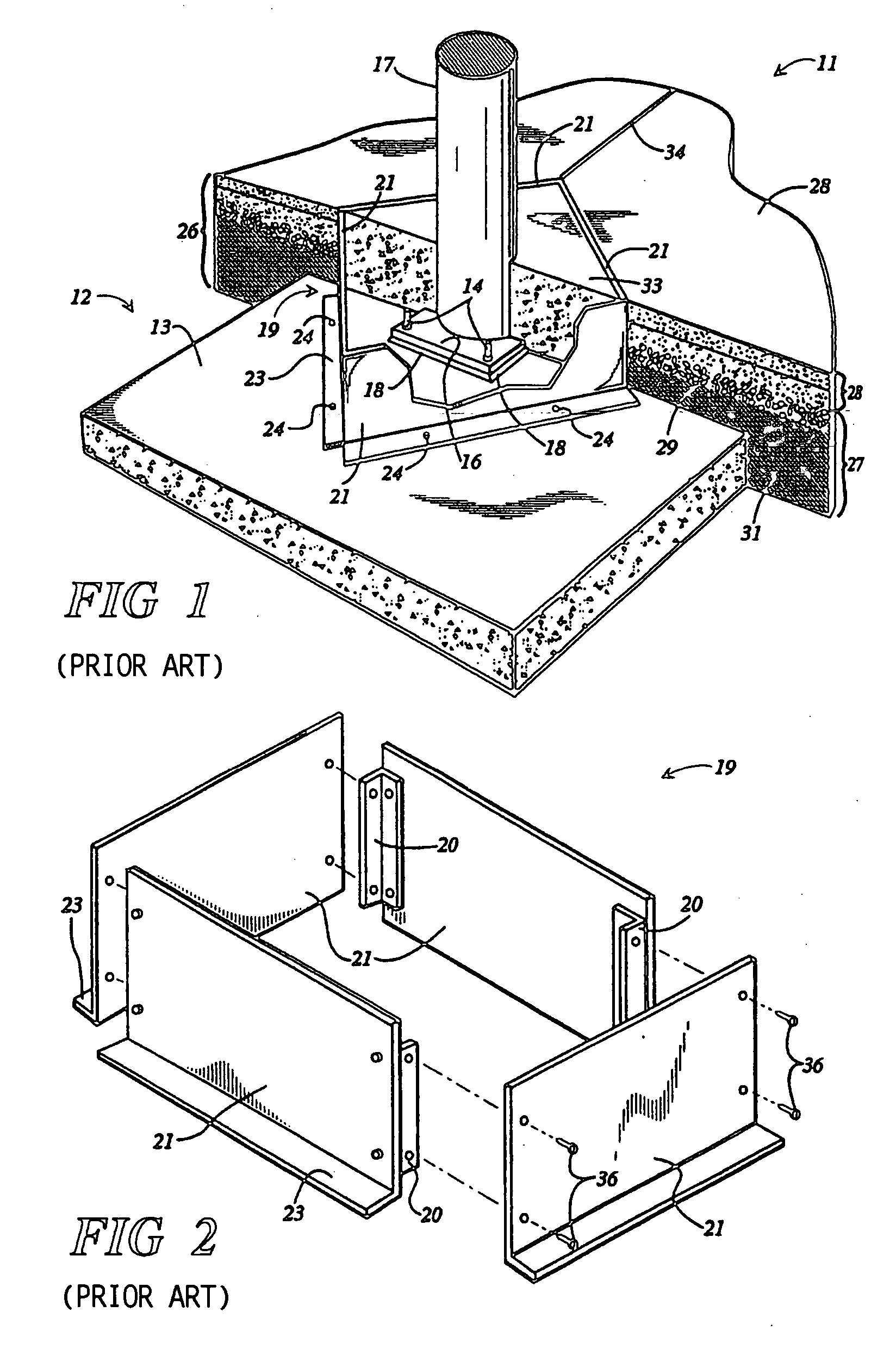

[0017] The floor structure 11 shown in FIG. 1 includes a generally rectangular concrete footing 12 that is formed with an upper load bearing surface 13. A set of anchor bolts 14 (only two of which are exposed in FIG. 1) are embedded within and extend upwardly from the upper surface 13 of the footing 12. The anchor bolts 14 provide means for securing the base plate 16 of a vertical support column 17 to the footing 12 using threaded nuts.

[0018] A generally rectangular open top form 19 is defined by four side panels 21 joined together at their ends. Each of the side panels 21 has a lower flange 23 that extends outwardly from the side panel along its bottom edge. The form 19 is mounted atop the footing 12 surrounding and isolating the base of support column 17 and is secured in place by means of concrete nails or other suitable fasteners 24 driven through the flanges 23 and into the concrete material of the footing 12. The form 19 is constructed from four similar side panels 21, and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com