Cuvette for an automated analyzer

a cuvette and analyzer technology, applied in the field of automatic analyzers, can solve the problems of limited automation applied, variable test results, high cost, etc., and achieve the effect of high degree of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

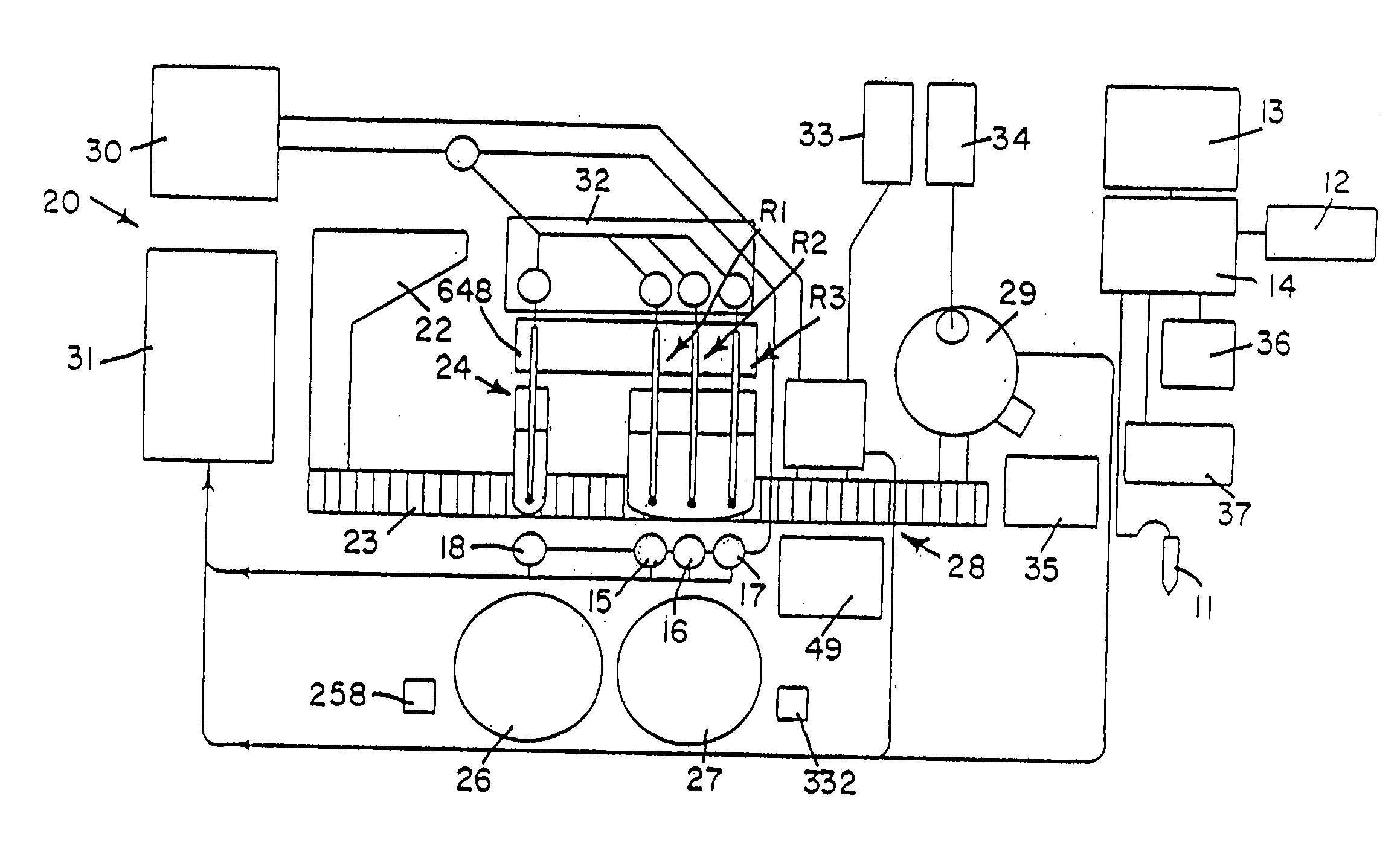

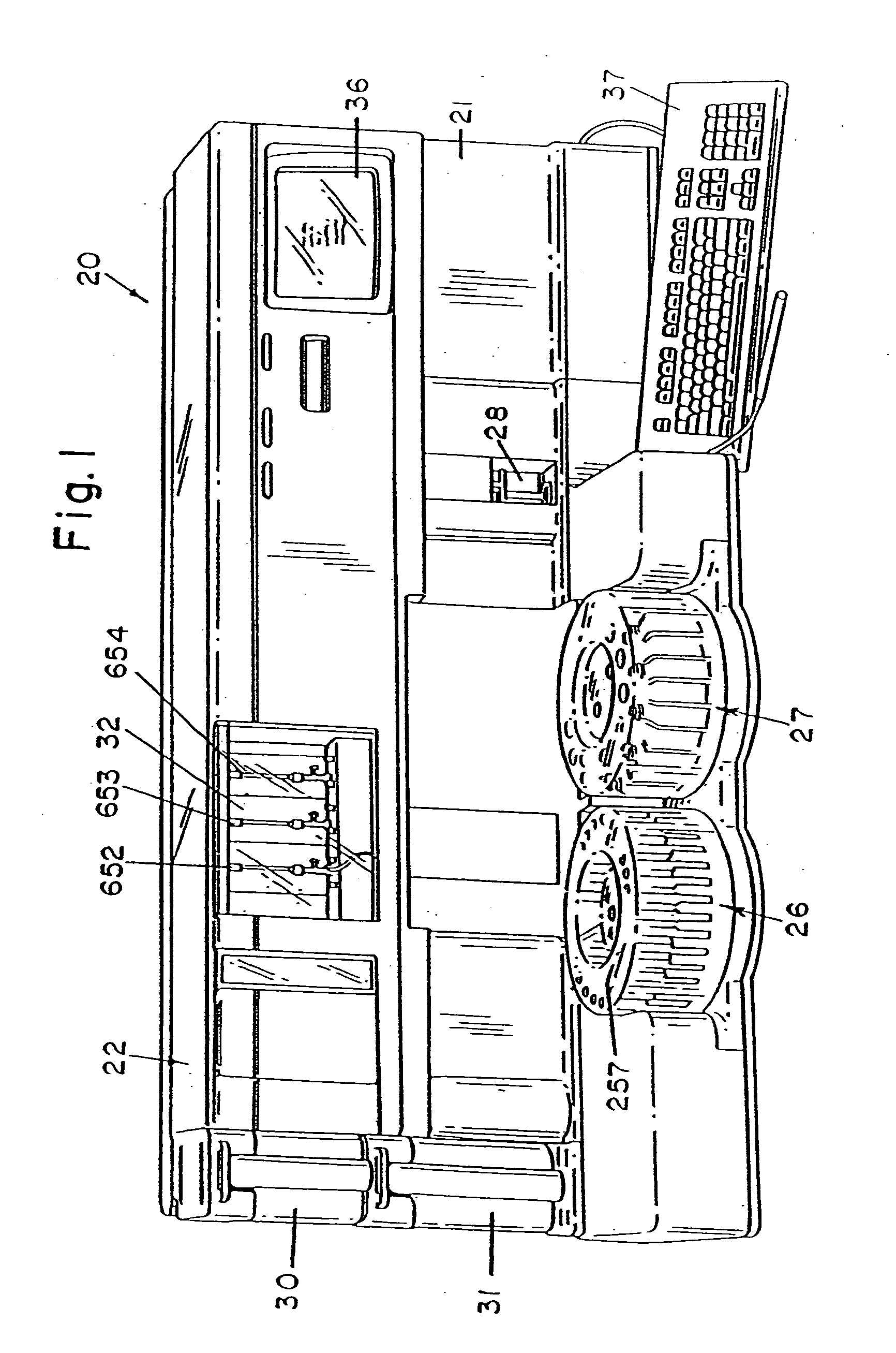

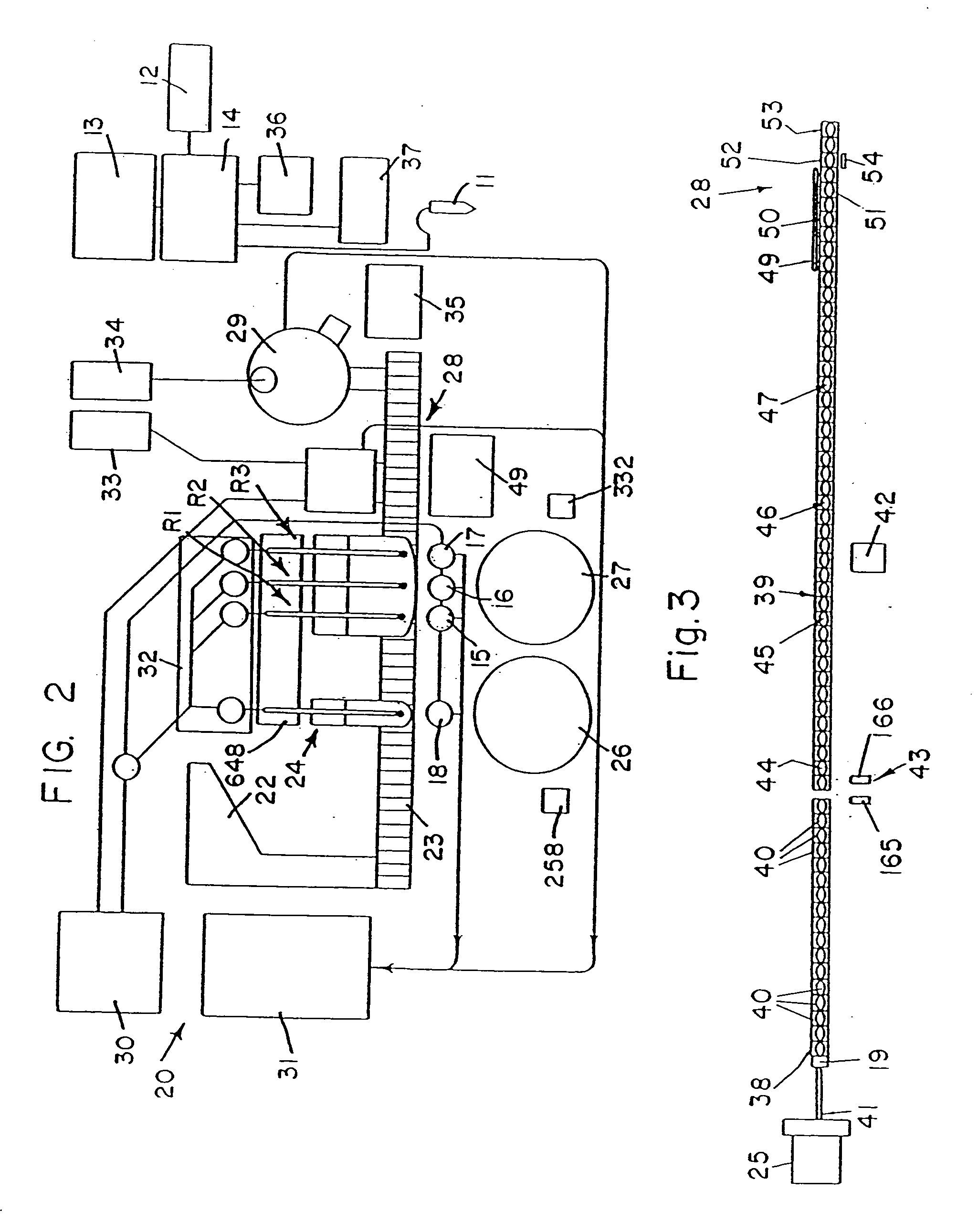

Method used

Image

Examples

example 1

Free Thyroxine (FT4)

[0278] A free thyroxine (FT4) assay has been developed for the above described automated analyzer. The FT4 assay is a competitive binding assay in which FT4 in a test sample competes with labeled T4 (tracer reagent) for a limited amount of T4 antiserum covalently coupled to the solid phase. In the preferred format of this assay acridinium ester is the label and paramagnetic particles serve as the solid phase. A test sample (25 uL.) acridininm ester labeled T4 (100 uL.) and anti-T4 paramagnetic particles (450 uL.) are dispensed by the analyzer into a cuvette and incubated for 7.5 minutes at 37° C. After incubation, magnetic separation and washes are performed as described prior to detection of the chemiluminescent signal. The amount of FT4 present in the test sample is determined by the level of the signed detected and is converted to a dose by a two-point data reduction algorithm.

[0279] The test assay has a sensitivity of 0.107 ng / dL. (minimum detectable dose ...

example 2

Human Chorionic Gonadotropin (hCG)

[0282] A human chorionic gonadotropin (hCG) assay has been developed for the above described automated analyzer. The hCG assay is a sandwich assay which utilizes an antibody-coated capture solid phase and a labeled antibody as a tracer reagent. In the preferred format of this assay acridinium ester is the label on a monoclonal antibody and polyclonal antibody coated paramagnetic particles serve as the capture solid phase. A test sample (50 uL.) and tracer reagent (100 uL.) are dispensed into a cuvette by the analyzer and incubated for 5.0 minutes at 37° C. The capture solid phase reagent (450 uL.) is then added to the cuvette followed by an additional incubation of 2.5 minutes. After the second incubation, magnetic separation and washes are performed as described above prior to detection of the chemiluminescent signal.

[0283] All data presented was generated based on a two-point calibration off a full standard master curve, consisting of ten stand...

example 3

[0287] A digoxin assay has been developed for the above described automated analyzer. The digoxin assay architecture is a hapten solid phase with a labeled antibody (tracer reagent). In the preferred format of this assay, the tracer reagent is an acridinium ester labeled monoclonal anti-digoxin antibody; and the solid phase is paramagnetic particles to which digoxin-apoferritin has been immobilized. A test sample (150 uL.) and tracer reagent (50 uL.) are dispensed into a cuvette by the analyzer and incubated for 2.5 minutes at 37° C. The solid phase reagent (250 uL.) is then added to the cuvette followed by an additional incubation of 5.0 minutes. After the second incubation, magnetic separation and washes are performed as described above prior to detection of the chemiluminescent signal.

[0288] All data presented was generated based upon a two-point recalibration off an original master curve. The master curve was generated using eight standards with valves ranging from zer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com