Muffler system for a compressor

a compressor and muffler technology, applied in the field of muffler systems, can solve the problems of affecting the operation efficiency of the compressor, affecting the noise source, and causing noise, so as to reduce the overall size of the compressor housing, reduce the pressure pulsation, and not adversely affect the compressor operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

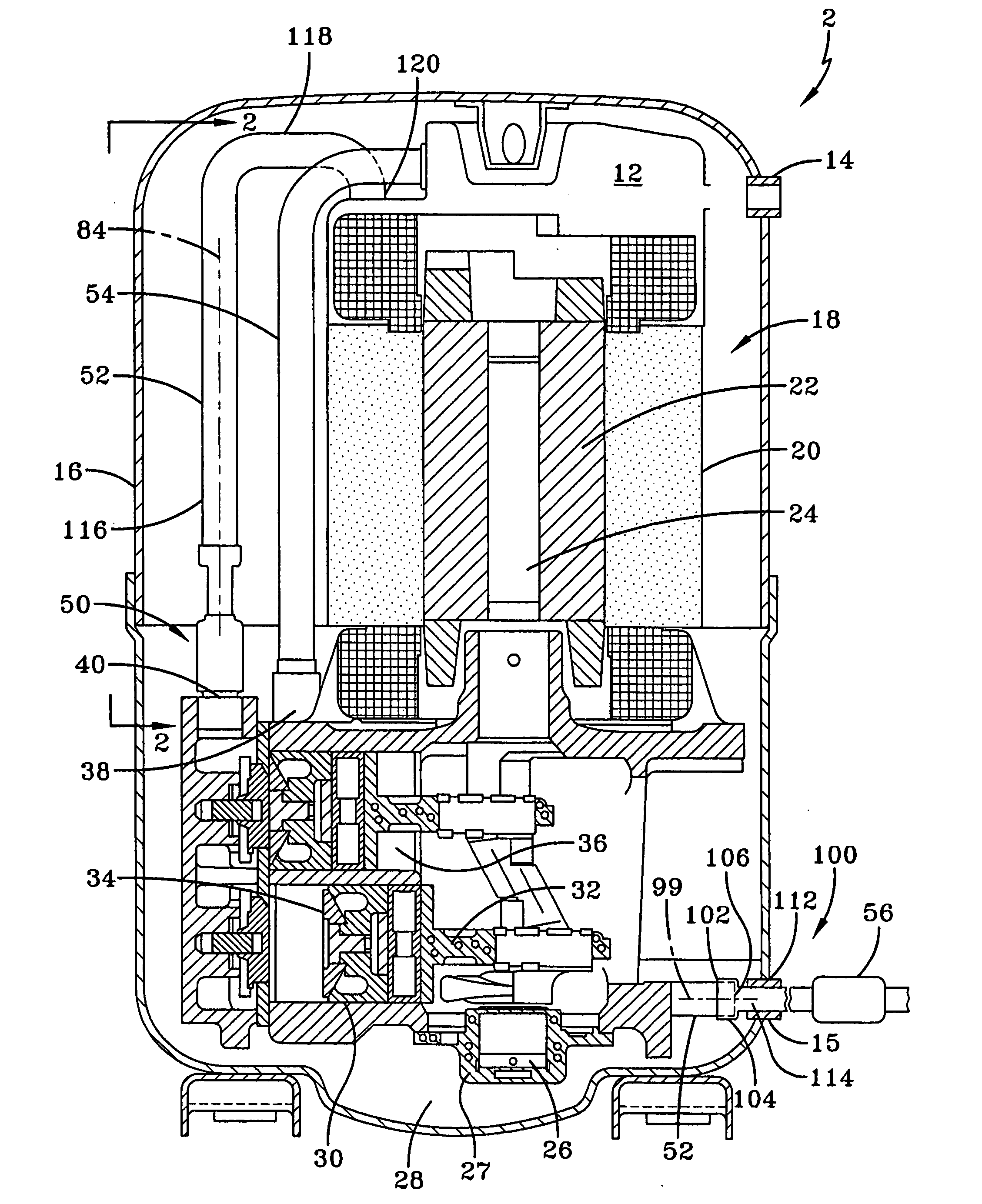

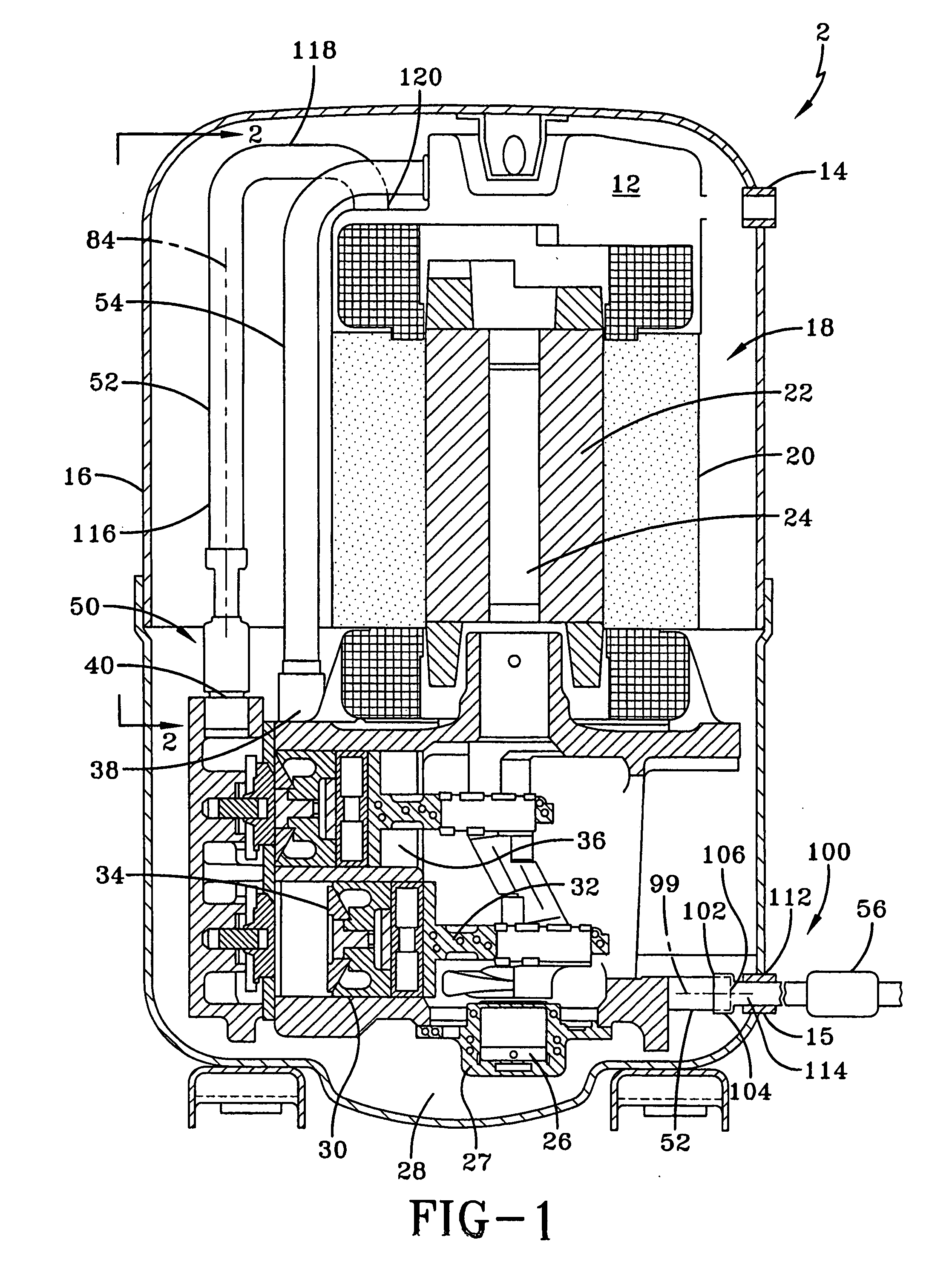

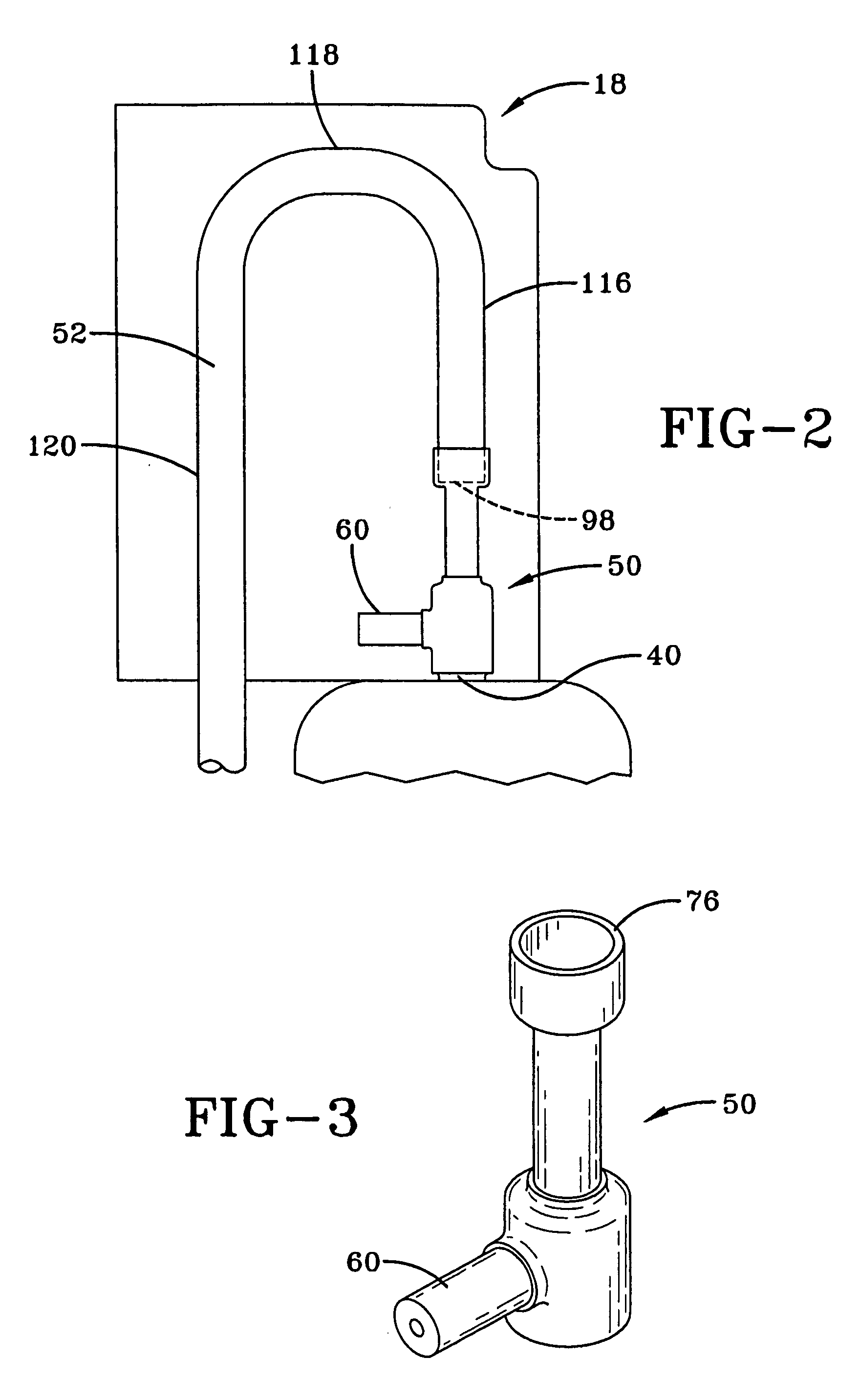

[0020] One embodiment of a compressor that incorporates the muffler system of the present invention is depicted in FIG. 1. Compressor 2 is connected to a conventional refrigeration or heating, ventilation and air conditioning and refrigeration (HVAC&R) system (not shown), such as may be found in a refrigerator, home or automobile. The HVAC&R system has a condenser, expansion device and evaporator in fluid communication. Compressor 2 is preferably a reciprocating compressor connected to an evaporator (not shown) by a suction line that enters the suction port 14 of compressor 2, although the muffler system may be used with any compressor, including, for example, a rotary, screw, or scroll compressor. Suction port 14 is in fluid communication with suction plenum 12. Refrigerant gas from the evaporator enters the low-pressure side of compressor 2 through suction port 14 and then flows to the suction plenum 12 before being compressed.

[0021] Compressor 2 includes an electrical motor 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com